The IS220PAICH1A is an indispensable key component within GE's Mark VIe control system, belonging to the PAIC series of Analog Input/Output modules. This module is specifically designed for industrial automation and process control applications, playing a vital role in critical industrial sectors such as power generation, petrochemicals, and heavy machinery. Acting as a bridge connecting the controller with field analog devices, the PAICH1A provides high-precision, highly reliable signal processing capabilities.

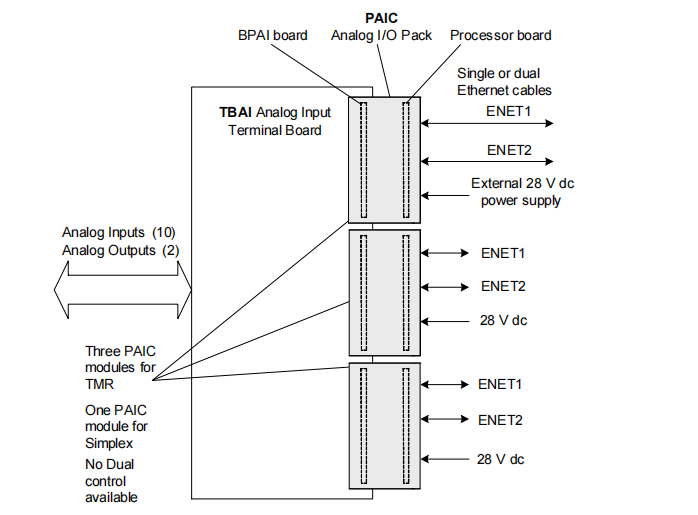

This module employs advanced electronic technology and sophisticated signal processing design, capable of handling multiple analog input and output signals simultaneously. Its compact structure and robust design make it suitable for long-term stable operation in harsh industrial environments. The PAICH1A supports Simplex and Triple Modular Redundant (TMR) configurations, offering users flexible system integration solutions to meet the reliability and safety requirements of different application scenarios.

Communicating with the control system via dual Ethernet interfaces and coupled with comprehensive diagnostic functions, the IS220PAICH1A can monitor the module status in real-time, ensuring system operational integrity and reliability. Its precise signal conditioning circuits and anti-interference design guarantee measurement accuracy and control precision in complex industrial environments.

2. Key Features and Functions

1. Multi-Channel Analog Signal Input

The IS220PAICH1A module provides 10 independent analog input channels, each offering high configuration flexibility:

Channels 1 through 8 support three input modes:

±5 V DC voltage input, suitable for standard industrial voltage signals.

±10 V DC voltage input, providing a wider measurement range.

4-20 mA current loop input, supporting the industrial standard current signal.

Channels 9 and 10 are dedicated to current input, configurable as:

4-20 mA standard industrial current signal.

±1 mA special low-current signal, meeting specific application needs.

All current input channels perform signal conversion via precision 250 Ω burden resistors located on the terminal board, converting the current signal into a voltage signal accessible for module acquisition. This design ensures accuracy and stability in signal acquisition.

2. High-Precision Analog Signal Output

The module integrates 2 independent 0-20 mA analog current outputs, each boasting excellent performance characteristics:

18 V Compliance Voltage, ensuring the ability to drive various industrial loads.

Maximum 800 Ω load driving capability, adapting to a wide range of field device requirements.

Supports Load Sharing functionality in TMR systems, where three redundant modules work cooperatively.

The output circuit includes comprehensive protection mechanisms to prevent damage from overloads and short circuits.

3. Flexible Communication Interface

The IS220PAICH1A is equipped with comprehensive communication interfaces to ensure reliable data transmission:

Dual RJ-45 Ethernet interfaces (ENET1 and ENET2) support network redundancy.

ENET1 serves as the primary communication interface, typically connected to the R controller network.

ENET2 acts as the redundant backup interface, automatically switching over if the primary network fails.

The module can operate normally on either network port, ensuring communication continuity.

4. Comprehensive Diagnostics and Status Monitoring

The module features multi-level self-diagnostic functions, including:

Power-On Self-Test (POST): Comprehensive checks of memory, Ethernet ports, and processor hardware.

Continuous Power Supply Monitoring: Real-time monitoring of internal +5V, ±15V power status.

Hardware Limit Checking: Configurable high/low limit monitoring for 4-20 mA input signals.

System Limit Checking: Setting alarm thresholds based on process requirements, supporting latching function.

Output Feedback Verification: Comparing output command values with actual feedback values to ensure output accuracy.

5. Advanced Signal Processing

The IS220PAICH1A utilizes professional signal processing technology to ensure signal quality:

Passive Low-Pass Filter: All input channels are equipped with a hardware filter having a cutoff frequency of 75.15 Hz.

Configurable Digital Filter: Provides multiple software filter options from 0.75 Hz to 12 Hz.

Excellent Common-Mode Rejection:

3. Detailed Working Principle

1. Analog Input Signal Processing Chain

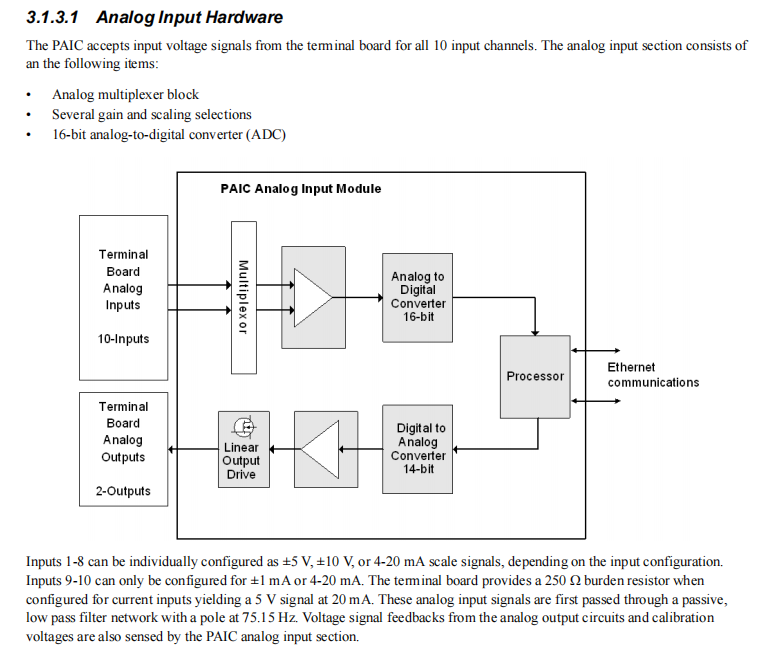

The analog input processing of the IS220PAICH1A is a precise, multi-stage process ensuring data acquisition accuracy and reliability:

-Signal Access Stage:

Analog signals from field sensors or transmitters are accessed via dedicated Analog Input Terminal Boards. For current input signals, the terminal board incorporates precision 250 Ω burden resistors. These resistors accurately convert the 4-20 mA current signal into a 1-5 V voltage signal based on Ohm's Law, ensuring linearity and accuracy in signal conversion. Voltage input signals are connected directly to the module without requiring additional signal conversion.

-Signal Conditioning Stage:

The converted voltage signal first enters the Signal Conditioning Circuit. This stage includes a single-pole passive low-pass filter with its corner frequency precisely set at 75.15 Hz. This hardware filter is the first line of defense against field Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI), effectively attenuating high-frequency noise while preserving useful low-frequency signal components. The filter design considers common interference frequencies in industrial environments, providing excellent noise suppression performance.

-Signal Acquisition and Conversion Stage:

The conditioned signal enters an Analog Multiplexer (MUX), which sequentially selects the 10 input channels according to a preset scanning sequence. The selected signal then enters a programmable gain amplifier, where it is scaled appropriately based on the configured input type (±5V, ±10V, or 1-5V) to match the optimal input range of the Analog-to-Digital Converter (ADC).

The core Analog-to-Digital Conversion is performed by a 16-bit high-precision ADC. The 16-bit resolution means the module can divide the full-scale signal into 65,536 discrete levels, providing extremely high measurement accuracy and the ability to resolve minute signal changes. The ADC's integral and differential linearity are strictly calibrated, ensuring conversion accuracy across the entire measurement range.

Data Processing and Transmission:

The digitized data undergoes preliminary processing by the module's internal processor, including unit conversion, filtering, and limit checking. The processed data is then transmitted in real-time to the upper-level controller via the dual Ethernet interfaces for functions such as closed-loop control, logic operations, trend recording, and Human-Machine Interface (HMI) display.

2. Analog Output Signal Generation Chain

The IS220PAICH1A's analog output generation employs a closed-loop control architecture to ensure output current precision and stability:

Command Reception and Processing:

The controller sends digital output commands to the PAICH1A module via the Ethernet network. The module's internal processor receives these commands and performs necessary verification and processing. The processed digital command is sent to the 14-bit Digital-to-Analog Converter (DAC).

Digital-to-Analog Conversion Stage:

The DAC converts the digital command into a corresponding high-precision reference voltage. The accuracy and stability of this reference voltage directly determine the final output current's accuracy. The 14-bit resolution provides sufficient output precision, capable of generating 16,384 discrete output levels, meeting the accuracy requirements of most industrial control applications.

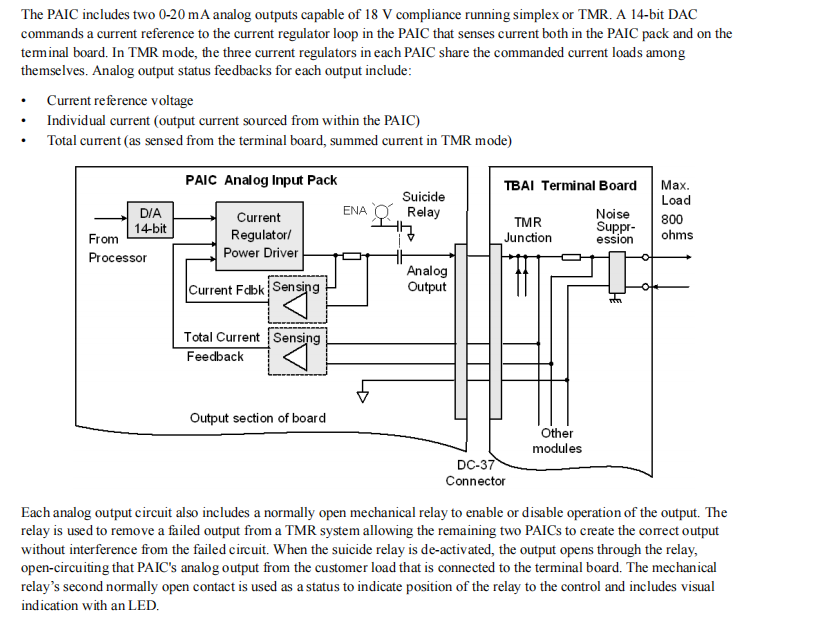

Current Regulation and Driving:

The reference voltage drives a precision Current Regulator/Power Driver Circuit. This circuit uses closed-loop control principles, monitoring the voltage drop across the output transistor in real-time to adjust the drive level, ensuring the output current accurately tracks the command value corresponding to the reference voltage. The current regulator employs linear regulation technology, providing low-noise, high-precision output characteristics.

Closed-Loop Feedback and Health Diagnostics:

Output current accuracy is ensured by a Multiple Feedback System:

Internal Current Sensing: The module internally measures its own output current value in real-time via a precision sense resistor.

External Total Current Sensing: In TMR applications, monitoring circuits on the terminal board measure the total current flowing through the load.

Comparison and Verification: The module continuously compares the DAC reference voltage, the internally sensed current, and the external total current feedback. Any significant discrepancy triggers a diagnostic alarm.

3. TMR Redundancy and Fault Isolation Mechanism

In high-reliability TMR applications, the PAICH1A demonstrates its unique design advantages:

Load Sharing Principle:

Three redundant PAIC modules work cooperatively through a dedicated Load Sharing Circuit. The current regulator of each module is designed to automatically adjust its output so that the three modules share the total load current collectively. For example, when the system requires a 12 mA output, each module precisely outputs approximately 4 mA, which are combined in parallel on the terminal board to achieve the required 12 mA.

"Suicide" Relay Mechanism:

Each analog output channel is equipped with a Normally Open mechanical relay, known as the "Suicide" relay. When the module detects an irrecoverable fault in its own output circuit through internal diagnostics, it proactively opens this relay, physically isolating the faulty module's output circuit from the load loop.

The significance of this fault isolation mechanism lies in:

Preventing Fault Propagation: The faulty module is immediately isolated, preventing it from affecting the normal operation of other healthy modules.

Maintaining System Operation: The remaining two healthy modules automatically readjust their outputs to maintain the total output current.

Supporting Online Maintenance: Faulty modules can be replaced without requiring system shutdown.

The relay status is monitored in real-time via auxiliary contacts and provides visual feedback through LED indicators on the module panel, offering maintenance personnel clear status indication.

4. Power Management and System Initialization

The IS220PAICH1A's power management system is designed considering the special requirements of industrial environments:

Power Input:

The module receives external 28 V DC power via a 3-pin power connector on its side. The power input circuit includes comprehensive overvoltage protection, reverse connection protection, and surge suppression circuits, ensuring the module is not damaged under abnormal power conditions.

Soft-Start Function:

The module incorporates a Soft-Start Circuit that gradually establishes operating voltage during power-up, effectively suppressing inrush current. This feature enables the module to support Hot-Swapping operations, allowing maintenance and replacement while the system is running, significantly improving system maintainability and availability.

Initialization Sequence:

After power-up, the module executes a strict initialization process:

Power Stability Detection: Waits for all internal power supplies to reach a stable state.

Hardware Self-Test: Comprehensive checks of the processor, memory, and interface circuits.

Terminal Board Identification: Reads the electronic ID of the connected terminal board to verify hardware compatibility.

Output Safety Control: All outputs remain disabled until the system is fully ready.

This orderly initialization process ensures the module does not cause maloperation in an unknown state, providing an important safety guarantee for the entire control system.

4. System Integration and Configuration

1. Hardware Compatibility

The IS220PAICH1A has specific compatibility requirements:

2. Installation Specifications

Correct installation is fundamental to ensuring long-term stable operation of the module:

Terminal Board Mounting: Securely mount the selected terminal board on standard rails or mounting plates.

Module Connection: Precisely align the PAICH1A module with the terminal board's DC-37 interface and insert it vertically.

Mechanical Securing: Lock the module onto the mounting bracket using the threaded studs adjacent to the Ethernet ports.

Connection Check: Ensure all connectors are fully seated and not subjected to external twisting forces.

3. Software Configuration

Module configuration is performed via ToolboxST software:

5. Diagnostics and Maintenance

The IS220PAICH1A provides comprehensive diagnostic functions, offering status information through various means:

1. Status Indication

ENAX LED: Yellow indicator light, displays the enable status of the output channel.

Processor LED: Provides module operational status and fault indication.

2. Diagnostic Alarms

The module can detect various abnormal states:

Signal Out-of-Limit: Input signal exceeds hardware or system-set ranges.

Communication Fault: Network connection interruption or data anomaly.

Hardware Failure: Failure of internal circuit components.

Temperature Anomaly: Module operating temperature exceeds the normal range.

3. Maintenance Guidance

Maintenance recommendations based on diagnostic information:

Regular Inspection: Connector status, heat dissipation condition.

Preventive Maintenance: Firmware updates, calibration verification.

Fault Handling: Take corresponding measures according to specific alarm codes.