The IS220PRTDH1B represents an advanced iteration within the distributed I/O module series for Mark VIe and Mark VIeS Control Systems, dedicated to high-fidelity Resistance Temperature Detector (RTD) signal acquisition. This module functions as an intelligent gateway, bridging the analog world of temperature sensors with the digital realm of modern control systems. It is engineered to deliver superior performance in demanding industrial environments where temperature measurement accuracy, system reliability, and diagnostic depth are paramount.

Operating as a critical node in the control architecture, the IS220PRTDH1B transcends basic signal conversion. It embodies a comprehensive data acquisition and processing unit that seamlessly integrates with system networks, providing not only temperature data but also vital health status information for both the module itself and the connected sensor field.

2. Detailed Functional Description

Advanced Signal Acquisition & Processing

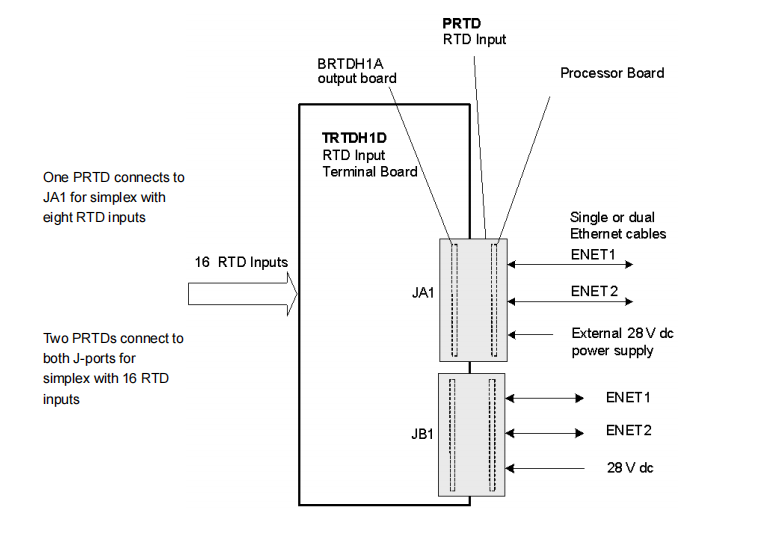

High-Density Input Handling: The module is architected to manage 8 discrete, high-resolution RTD input channels concurrently. Its design allows for system scalability; deploying two PRTDH1B modules on a single TRTDH2D terminal board facilitates the management of 16 independent temperature points, providing flexible I/O density.

Extended Sensor Library: Beyond standard RTD types (PT100, PT200, N120, CU10), the PRTDH1B's firmware incorporates linearization curves for specialized sensors, enabling precise temperature tracking across a wider operational envelope. This includes enhanced support for custom platinum curves and high-temperature variants.

Intelligent Lead Resistance Compensation: The module's 3-wire measurement technique is augmented by sophisticated algorithms that dynamically compensate for lead wire resistance variations, ensuring measurement integrity even over long cable runs.

Robust System Integration & Connectivity

Unified Terminal Board Interface: A keyed DC-37 pin connector ensures secure, error-proof mating with compatible terminal boards (TRTDH1D, TRTDH2D, SRTD), facilitating rapid module replacement and minimizing downtime.

Dual-Port Ethernet Communication: Featuring two independent RJ-45 ports (ENET1, ENET2), the module supports robust network architectures. It enables both redundant network paths and sophisticated traffic management schemes, enhancing data availability and network resilience.

Conditional Power Management: The integrated 28V DC power input circuit is designed with advanced soft-start technology and comprehensive protection against over-voltage, reverse polarity, and transients, safeguarding the module and its connected terminal board.

Comprehensive Diagnostic & Prognostic Capabilities

Hardware Limit Violations: Non-configurable, firmware-defined boundaries instantly flag sensor failures or catastrophic wiring faults (shorts/opens), automatically isolating the affected channel to prevent cross-talk.

Configurable System Limits: User-defined high/low temperature alarms for process monitoring, with flexible latching and auto-reset behaviors.

Internal Integrity Checks: Continuous self-monitoring of reference voltages, A/D converter performance, and communication sub-systems.

Multi-Tier Status Indication: A comprehensive array of multi-color LEDs provides immediate visual feedback on operational status, network activity, fault conditions, and power integrity, enabling at-a-glance assessment by field personnel.

Hierarchical Fault Detection: The module implements a layered diagnostic strategy:

Predictive Health Monitoring: The module tracks operational parameters such as internal temperature and power supply quality, providing early warnings of potential issues before they lead to failure.

3. In-Depth Working Principle Analysis

The operational paradigm of the IS220PRTDH1B is built upon a foundation of precision analog design, high-speed digital signal processing, and secure data communication.

Precision Excitation & Isolated Measurement

Multiplexed Current Source: The module employs a highly stable, multiplexed 10 mA DC current source to excite each RTD sequentially. This pulsed excitation strategy minimizes self-heating effects in the sensor, a critical factor for high-accuracy measurements. The timing of these pulses is precisely synchronized to the selected scan rate.

Galvanic Isolation Barrier: A fundamental safety and performance feature is the complete galvanic isolation between the RTD field side and the logic/communication side. This isolation barrier, capable of withstanding high voltages, breaks ground loops, suppresses common-mode noise, and protects the control system from hazardous field potentials.

High-Impedance Differential Sensing: The voltage drop across the RTD is measured using a high-impedance differential amplifier. This configuration rejects noise common to both signal leads, significantly enhancing signal integrity in electrically noisy industrial environments.

High-Speed Digital Conversion & Signal Conditioning

High-Noise-Rejection Mode (4 Hz): Optimized for standard process monitoring, it incorporates powerful digital filters tuned to reject 50/60 Hz power line interference and its harmonics.

High-Speed Mode (25 Hz): Designed for dynamic process applications like airflow or exhaust temperature monitoring, this mode provides a faster update rate, capturing rapid temperature transients at the expense of some noise immunity.

Advanced A/D Conversion: A high-performance 14-bit Analog-to-Digital Converter captures the analog voltage with exceptional resolution. Oversampling and digital filtering techniques are employed to increase the effective number of bits (ENOB) and improve the signal-to-noise ratio.

Adaptive Scan Modes:

Firmware-Based Linearization: The raw digital counts are processed by the module's powerful firmware, which applies complex, multi-segment polynomial linearization algorithms specific to the selected RTDType. This ensures non-linearity errors are minimized across the entire temperature span.

Data Management & Network Protocol Handling

The processed temperature values, along with channel status bits and diagnostic data, are packetized using efficient, deterministic protocols.

The integrated dual Ethernet controllers manage all layers of network communication, ensuring timely and reliable data delivery to the Mark VIe controller, even under heavy network traffic conditions.

4. Installation and Configuration

Modular Hardware Deployment

The PRTDH1B features a tool-less, direct-plug design. The module aligns and connects seamlessly to the terminal board, with positive latching fasteners ensuring a secure connection resistant to vibration. The optional mounting bracket provides additional mechanical strain relief.

Streamlined Software Setup

Configuration is performed intuitively within the ToolboxST environment. Key setup tasks include:

Sensor Configuration: Assigning the RTDType and RTDGain for each channel.

Performance Tuning: Selecting the GroupRate (scan speed/filtering) appropriate for the application.

Alarm Management: Enabling and configuring SysLimit values and latching behavior.

System Integration: Verifying the RTDUnit consistency across the control system to prevent unit mismatch errors.

5. Diagnostics and Specific Alarms

The IS220PRTDH1B enhances diagnostic visibility with precise alarm reporting:

Sensor-Level Alarms (32-39, 64-71, 96-103): These alarms are triggered by specific fault conditions—Voltage, Current, or Resistance out of range—on individual channels, pinpointing the exact nature and location of a field issue.

Module Integrity Alarms (128, 144): These critical alarms indicate failures of internal hardware reference circuits (Voltage, Current), necessitating module replacement.

Proactive System Alarms: The module generates alerts for communication faults (LINK_OK_PRTD_R), overall module health (L3DIAG_PRTD_R), and internal power supply status (PS18V_PRTD_R, PS28V_PRTD_R).

6. Detailed Comparison: IS220PRTDH1B vs. IS220PRTDH1A

This section delineates the key technical and functional differentiators between the IS220PRTDH1B and its predecessor, the IS220PRTDH1A.

| Feature/Aspect | IS220PRTDH1A | IS220PRTDH1B |

| Core Processor | BPPB processor board. | BPPC processor board. Offers enhanced processing power and memory, supporting more complex functions and future firmware enhancements. |

| Software Compatibility | Compatible with a broad range of older ControlST versions. | Requires ControlST software suite V04.06 or later. This ensures access to the latest features and security updates but may necessitate a system software upgrade. |

| Environmental Rating | Operating Temperature: -30°C to +65°C. | Extended Operating Temperature: -40°C to +70°C. Offers greater robustness for harsh environments, both in extreme cold and high ambient heat. |

| Diagnostic Depth | Standard diagnostic capabilities as defined for the platform. | Enhanced diagnostic resolution and potentially more detailed status reporting, leveraging the increased processing capability of the BPPC board. |

| Firmware Capabilities | Firmware feature set is locked to the capabilities of the BPPB platform. | Capable of running more advanced firmware with potential for features like improved noise filtering algorithms, sensor diagnostics, and data logging. |

| Hardware Integration | Standard integration with terminal boards. | Maintains full physical and functional compatibility with terminal boards (TRTDH1D/H2D, SRTD), ensuring a drop-in replacement in most cases, subject to software version. |

Conclusion and Selection Guidance

The IS220PRTDH1B is not merely a successor to the IS220PRTDH1A; it is a strategic upgrade path for users seeking to leverage the full capabilities of modern Mark VIe/VleS systems. Its core differentiator is the BPPC processor, which unlocks higher performance, extended environmental limits, and a foundation for future software advancements.

Selection Criteria:

Choose IS220PRTDH1B for: New installations, system upgrades where ControlST V04.06+ is available, applications demanding extended temperature operation, and projects requiring the highest level of diagnostic insight and future-proofing.

IS220PRTDH1A remains suitable for: Legacy systems operating with older ControlST versions, environments within its specified temperature range, and applications where the enhanced features of the BPPC are not immediately required.

The IS220PRTDH1B thus establishes itself as the preferred choice for forward-looking control system architectures, delivering enhanced robustness, software currency, and operational intelligence for critical temperature monitoring applications.