The Model 330102 is a key component of Bently Nevada's 3300 XL series 8mm Proximity Transducer System. It is a high-performance eddy current probe featuring 3/8-24 UNF standard mounting threads and a protective stainless steel armor. This probe, together with a 3300 XL extension cable and a 3300 XL Proximitor Sensor, forms a complete measurement system for the continuous and precise monitoring of vibration and position in rotating machinery.

As the front-end sensing element of the proximity transducer system, the 330102 probe is renowned for its enhanced mechanical robustness and environmental adaptability. Its design is intended to meet the requirements of the most demanding industrial environments, particularly in applications where there is a risk of physical damage, oil contamination, moisture, or where additional mechanical protection is required. The probe fully complies with the American Petroleum Institute's (API) 670 Standard for mechanical configuration, linear range, accuracy, and temperature stability. It is an ideal choice for condition monitoring and protection of large fluid-film bearing machines such as steam turbines, gas turbines, compressors, pumps, and generators.

2. Key Features

1. Rugged Armored Protection

The core characteristic of the 330102 model is its flexible stainless steel armor. This armor provides exceptional physical protection for the probe's cable, effectively resisting:

Mechanical Abrasion and Crushing: Prevents cable damage from friction, stepping on, or scraping against other components during installation or operation.

Accidental Pulling: The connection between the armor and the probe is designed to withstand pull forces up to 330 N (75 lbf), ensuring connection reliability in complex wiring environments.

Rodent Biting: Protects against cable damage caused by small animals in specific environments.

The armor is covered with a Fluoroethylene Propylene (FEP) jacket, offering both corrosion resistance and insulation properties.

2. Advanced Probe Structure and Materials

Patented TipLoc Molding Technology: The connection between the probe tip (which houses the sensing coil) and the probe body uses a special molding process, creating an extremely robust and sealed unit that effectively prevents moisture or contaminants from intruding from the tip, enhancing the probe's long-term stability.

Patented CableLoc Design: Ensures a robust connection between the probe cable and the probe rear, achieving a high pull-off strength of 330 N.

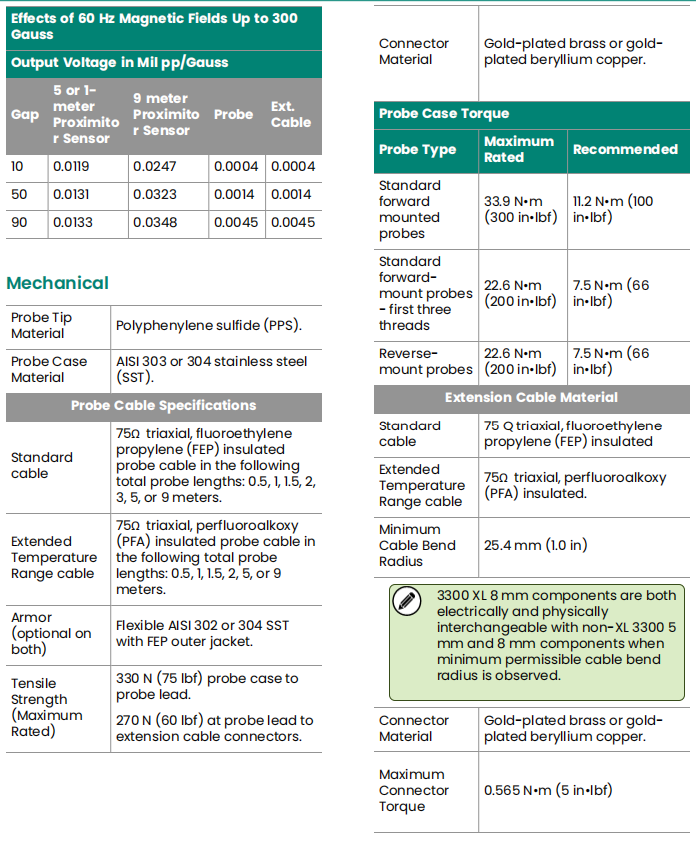

Corrosion-Resistant Materials: The probe body is made from AISI 303 or 304 stainless steel, providing good resistance to environmental corrosion. The probe tip is made from Polyphenylene Sulfide (PPS) plastic, a material known for its excellent high-temperature resistance, chemical resistance, and mechanical strength.

3. Plug-and-Play and Full Compatibility

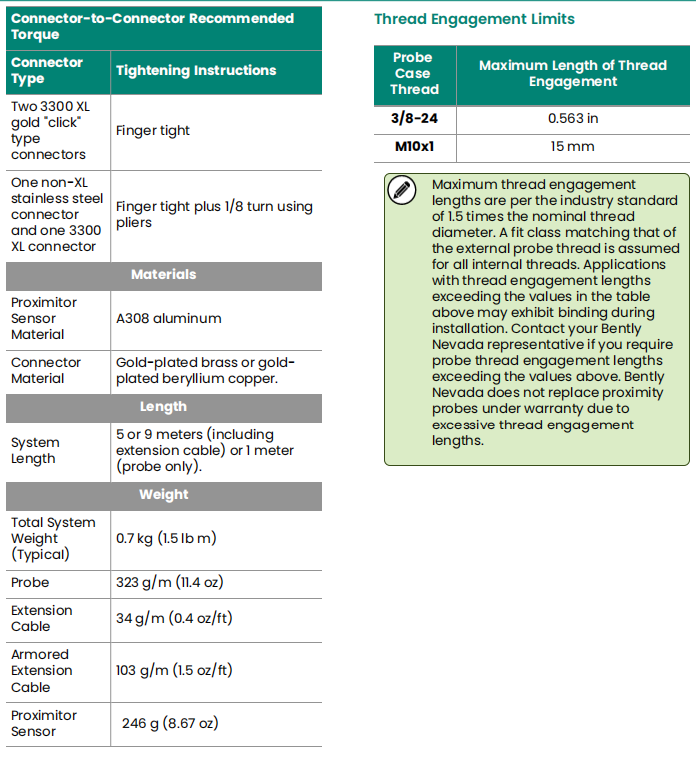

The 330102 probe utilizes ClickLoc connectors. These connectors offer the following advantages:

Quick Installation: Simply finger-tighten until a "click" is heard, indicating proper engagement. No special tools are required.

Anti-Loosening Design: A specially engineered locking mechanism prevents the connectors from loosening in vibrating environments.

Full System Compatibility: The 330102 probe is electrically and mechanically fully compatible with all 3300 XL series extension cables and Proximitor Sensors. It is also backward compatible with non-XL series 3300 5mm and 8mm system components. This full interchangeability means users do not need to match or bench-calibrate individual components in the field, greatly simplifying inventory and maintenance procedures.

4. Environmental Sealing Option (Optional)

Users can optionally select the FluidLoc cable option. This option uses a special internal seal structure within the cable to effectively prevent lubricating oil or other liquids from inside the machine from migrating along the interior of the cable to the outside, meeting applications with stringent sealing requirements.

3. Detailed Working Principle

The 330102 probe, as the core detection element of the eddy current proximity transducer system, operates based on the eddy current effect in electromagnetic induction. The working process of the entire system is a sophisticated procedure that accurately converts a physical gap (distance) into a linear DC voltage signal.

1. Core Physical Principle: The Eddy Current Effect

Encapsulated within the tip of the 330102 probe is a precision coil. When the system is powered, the rear 3300 XL Proximitor Sensor applies a high-frequency alternating current (typically 1 MHz or 2 MHz) to this coil. According to Faraday's Law of Electromagnetic Induction, this alternating current generates an alternating magnetic field of the same frequency in the space surrounding the probe tip.

When this alternating magnetic field approaches a conductive metal surface (typically a machine shaft, made of materials like AISI 4140 steel), it induces circulating, swirl-like currents called eddy currents in the surface layer of the metal. The existence of these eddy currents, in turn, generates a new alternating magnetic field opposing the original field, in accordance with Lenz's Law.

2. Impedance Change and Gap Measurement

The opposing magnetic field generated by the eddy currents has a canceling effect (i.e., "mutual inductance" effect) on the probe coil's own magnetic field. This interaction directly affects the effective impedance of the probe coil. The pattern of change is as follows:

Decreasing Gap: When the gap between the probe and the target surface decreases, the magnetic field coupling strengthens, the eddy current effect becomes more significant, causing a significant increase in coil impedance.

Increasing Gap: When the gap increases, the magnetic field coupling weakens, the eddy current effect diminishes, and the increase in coil impedance slows or relatively decreases.

Therefore, the distance of the gap between the probe and the metal surface has a single, deterministic functional relationship with the change in the probe coil's impedance. This is the fundamental physical basis enabling the entire system to perform measurements.

3. Signal Conditioning and Linearized Output

The minute changes in the probe coil's impedance are detected and processed by the connected 3300 XL Proximitor Sensor at the rear. The Proximitor contains a precise oscillator circuit and signal conditioning circuitry.

Demodulation: The Proximitor first demodulates the high-frequency carrier signal containing the gap information, extracting the low-frequency voltage signal corresponding to the impedance change.

Linearization Processing: The original voltage-gap relationship curve is nonlinear. The Proximitor incorporates advanced linearization circuitry that, through compensation algorithms, converts the nonlinear signal into a DC voltage output signal that is highly linear and proportional to the gap change.

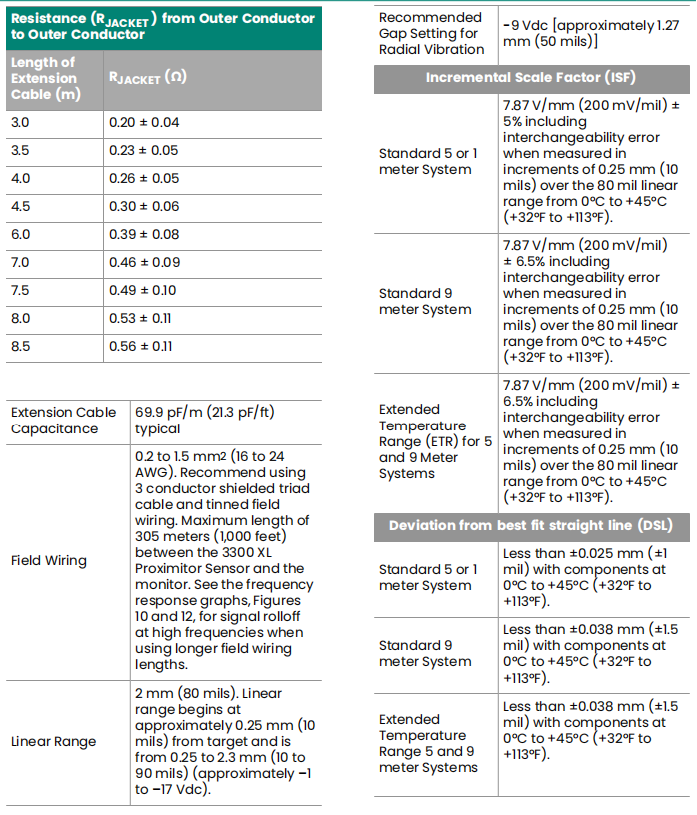

Standardized Output: After conditioning, the system outputs a DC voltage signal typically ranging from approximately -1 Vdc to -17 Vdc, corresponding to the start and end of the probe's linear range (typically 0.25 mm to 2.3 mm, or 10 mils to 90 mils). Its Incremental Scale Factor (ISF) is typically 7.87 V/mm ±5% (or 200 mV/mil), meaning the output voltage changes by approximately 7.87 Volts per millimeter of gap change.

4. Capability for Static and Dynamic Measurement

The sophistication of the system design lies in its ability to simultaneously measure both static (position) and dynamic (vibration) components.

Static Position: The average value (DC component) of the output voltage directly represents the average gap or position between the probe and the target surface. This is crucial for monitoring axial position, radial bearing clearance, etc.

Dynamic Vibration: The rapid fluctuations of the output voltage around its average value (AC component) accurately reflect the vibration of the target surface. The amplitude of this AC signal represents the peak-to-peak vibration displacement, and its frequency corresponds to the vibration frequency.

5. System Integration and Anti-Interference Design

The 330102 probe works in concert with the rest of the system to ensure measurement accuracy:

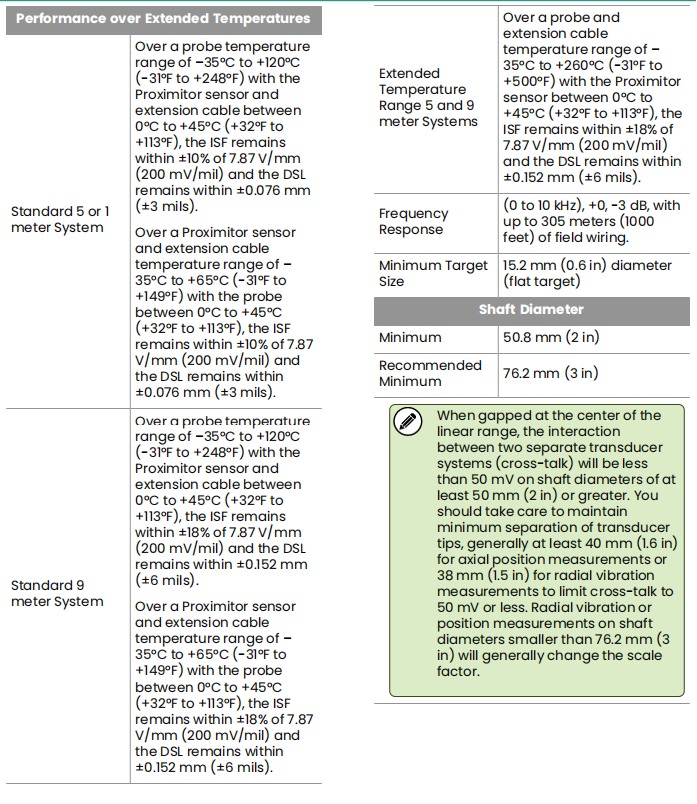

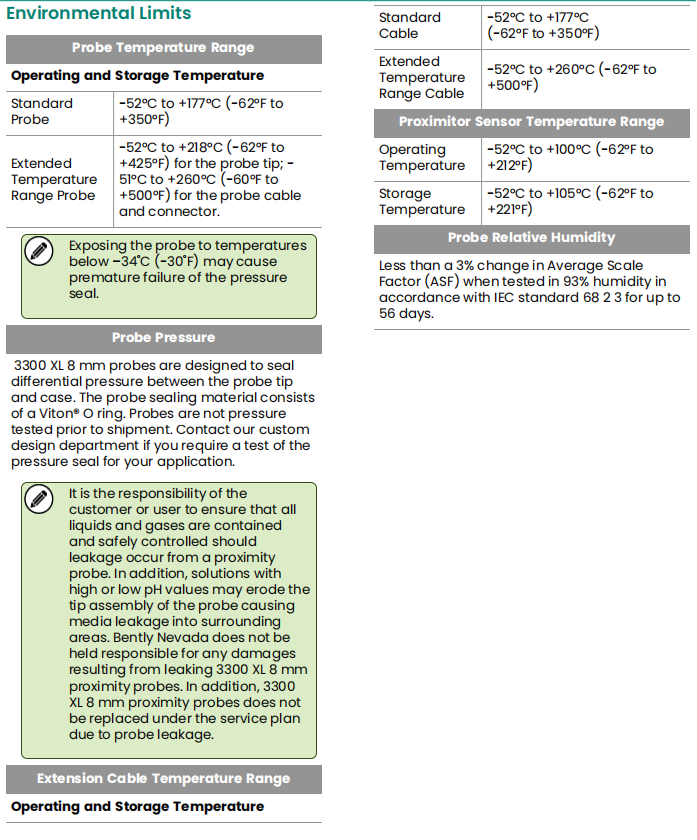

Temperature Stability: The resistance of the probe and cable changes with temperature. The 3300 XL system, through careful component selection and circuit design, controls the effects of temperature drift within allowable limits over a wide temperature range (e.g., ±10% ISF change for probe temperatures from -35°C to +120°C).

Resistance to RFI/EMI: The 3300 XL Proximitor Sensor has high immunity to Radio Frequency and Electromagnetic Interference, allowing the entire system to operate without significant impact from nearby radio signals, even when installed in fiberglass housings, meeting CE mark requirements without the need for expensive shielded conduit.

Target Material Calibration: The system is default calibrated for AISI 4140 steel targets. For other materials, sensitivity will vary due to differences in the strength of the eddy current effect and must be specified when ordering.

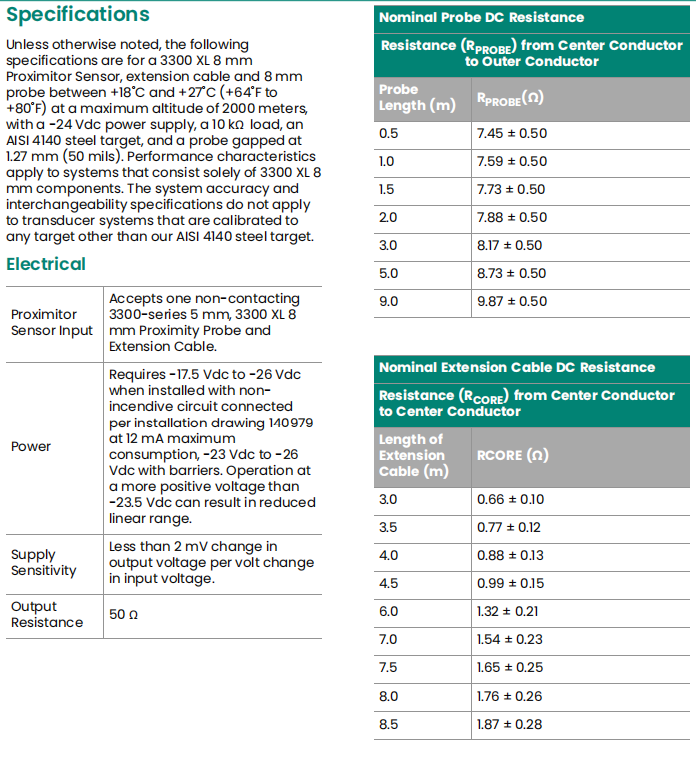

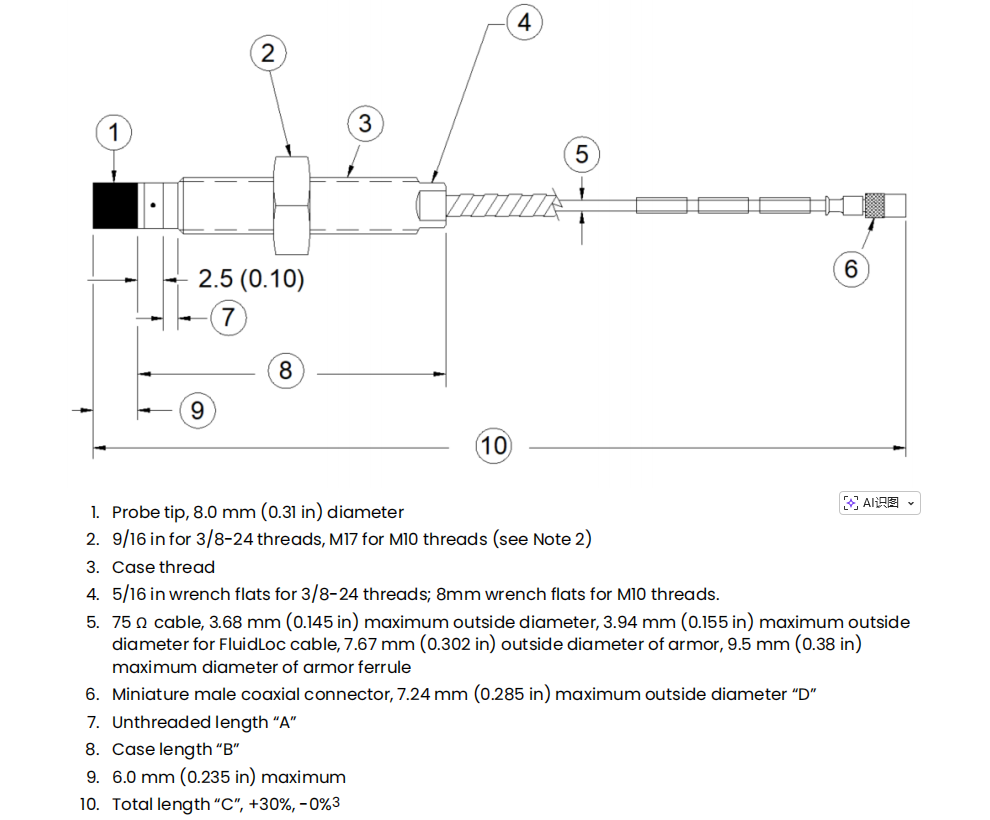

4. Key Specifications Summary

| Parameter | 330102 Specification |

| Probe Diameter | 8 mm |

| Mounting Thread | 3/8-24 UNF |

| Armor | Yes, AISI 302/304 Stainless Steel with FEP outer jacket |

| Probe Cable Type | 750 Triaxial, FEP Insulated (Standard) |

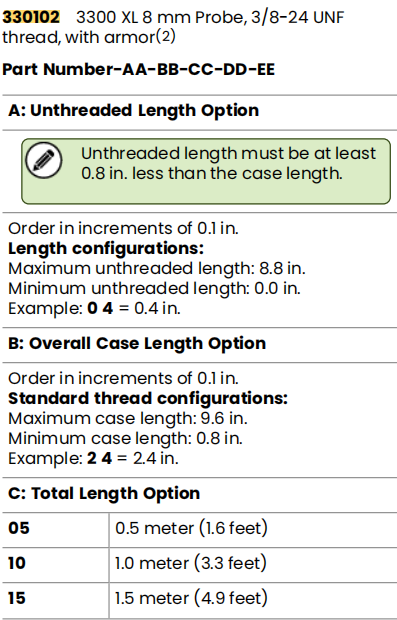

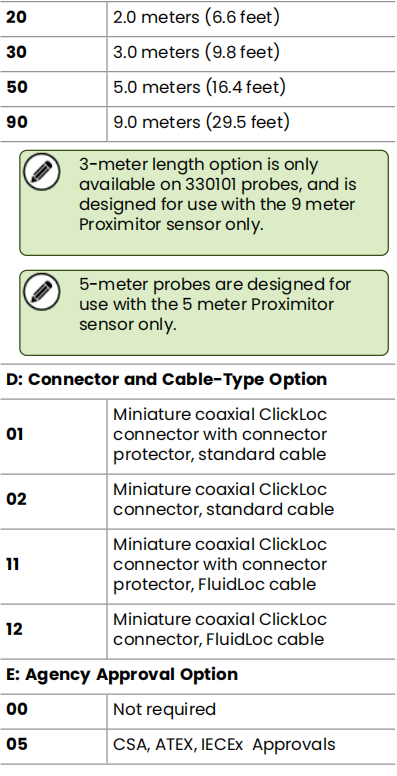

| Total Length Options | 0.5, 1.0, 1.5, 2.0, 3.0, 5.0, 9.0 meters |

| Connector | Miniature Coaxial ClickLoc Connector (Gold-Plated) |

| Recommended Gap Setting | 1.27 mm (50 mils), corresponding to ~-9 Vdc output |

| Linear Range | 0.25 mm to 2.3 mm (10 to 90 mils) |

| Incremental Scale Factor | 7.87 V/mm (200 mV/mil) ±5% (5-meter system) |

| Temperature Range | Standard Probe: -52°C to +177°C (Probe Cable & Connector) |

| Tensile Strength | Probe Case to Lead: 330 N (75 lbf) |

| Minimum Bend Radius | 25.4 mm (1.0 inch) |

| Agency Approvals | Optional CSA, ATEX, IECEx (Specify Option EE=05 when ordering) |

5. Application Scenarios

The 330102 armored probe is widely used for vibration and position monitoring in the following scenarios:

Radial Vibration Monitoring: Installed on bearing housings to monitor relative shaft vibration.

Axial Position Monitoring: Monitors rotor thrust bearing clearance to prevent rubbing and excessive displacement.

Keyphasor Reference: Used with a Keyphasor notch to provide speed and phase reference signals.

Harsh Environments: Suitable for any installation location with potential physical damage risks, severe oil contamination, or requiring extra mechanical protection.