The 330180 3300 XL Proximitor Sensor is a core component of the Bently Nevada 3300 XL 8 mm Proximity Transducer System. Together with the 8 mm proximity probe and extension cable, it forms a complete eddy current displacement sensing system. This sensor is specifically designed for vibration, position, and speed monitoring of industrial rotating machinery. It features high precision, high stability, and strong interference immunity, making it widely used for monitoring critical equipment in industries such as oil and gas, power generation, and chemicals.

II. Key Features

High-Precision Signal Processing

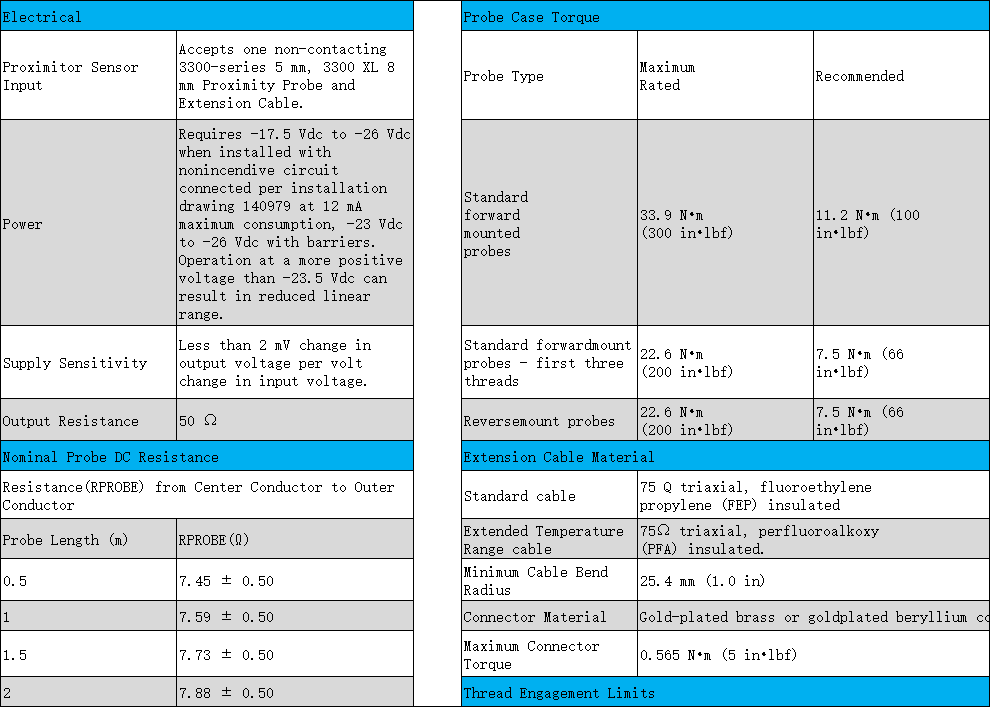

The 3300 XL Proximitor Sensor can receive signals from 3300 series 5 mm or 8 mm proximity probes and convert them into a DC voltage output proportional to the distance between the probe tip and the target. The system can simultaneously measure both static position and dynamic vibration signals, making it suitable for various monitoring tasks such as shaft displacement, vibration amplitude, and phase reference.

Full System Interchangeability

The 3300 XL sensor is fully compatible with earlier non-XL series 5 mm and 8 mm components, requiring no recalibration or matching. This reduces maintenance and spare parts management complexity.

Strong Interference Immunity

It possesses excellent Radio Frequency Interference (RFI) and Electromagnetic Interference (EMI) immunity. It can be installed in fiberglass housings without requiring additional shielded conduit or metallic enclosures, complying with European CE marking requirements. Output variation is minimal even under 60 Hz magnetic field strengths up to 300 Gauss, ensuring stable operation in strong electromagnetic environments.

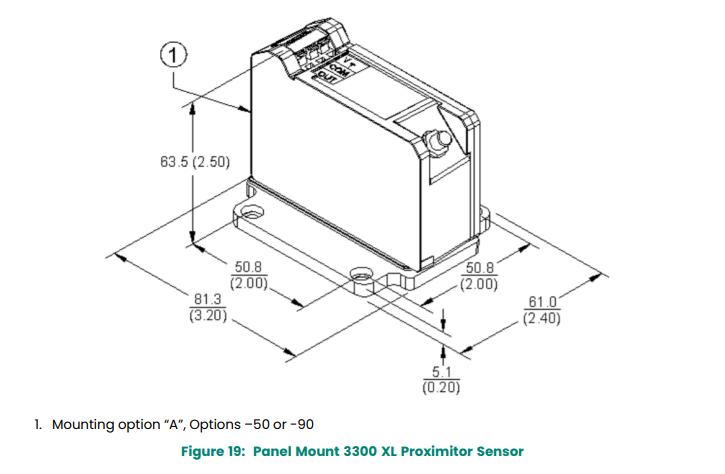

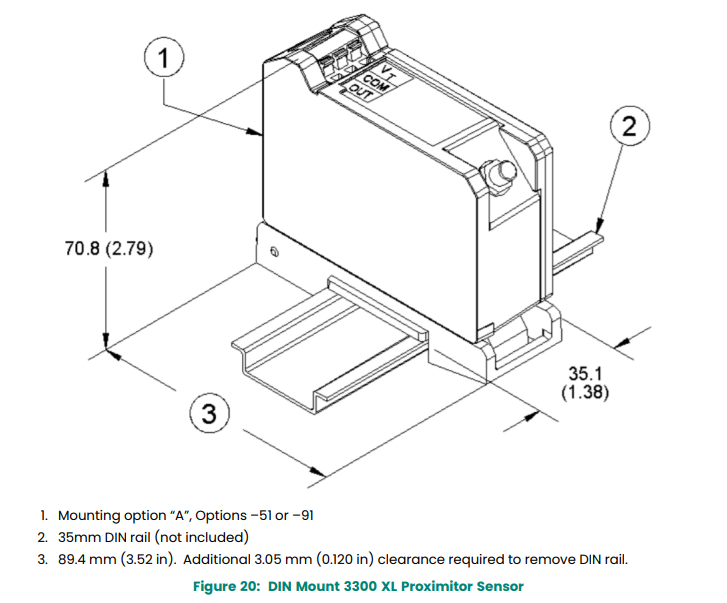

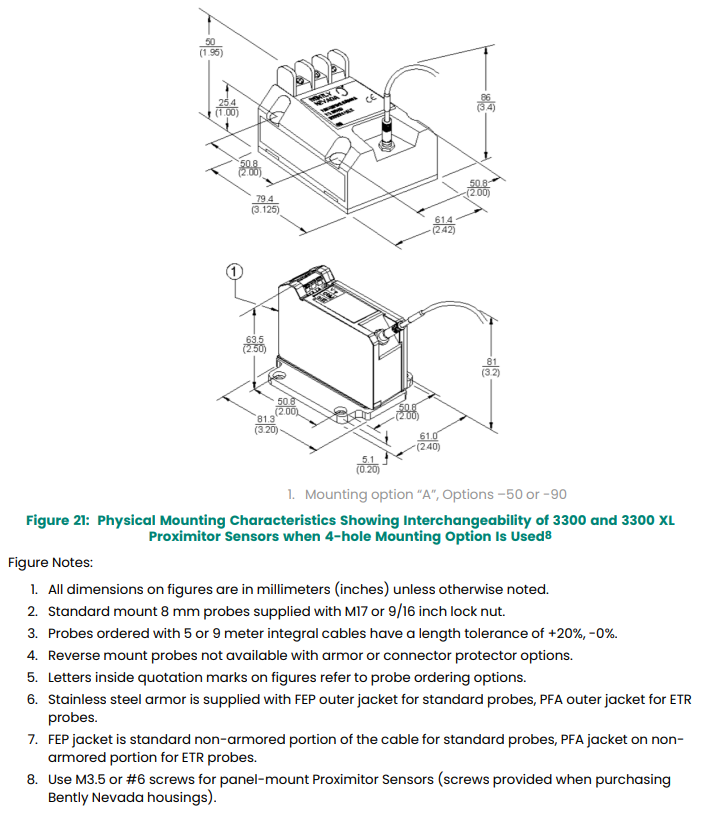

Flexible Installation Options

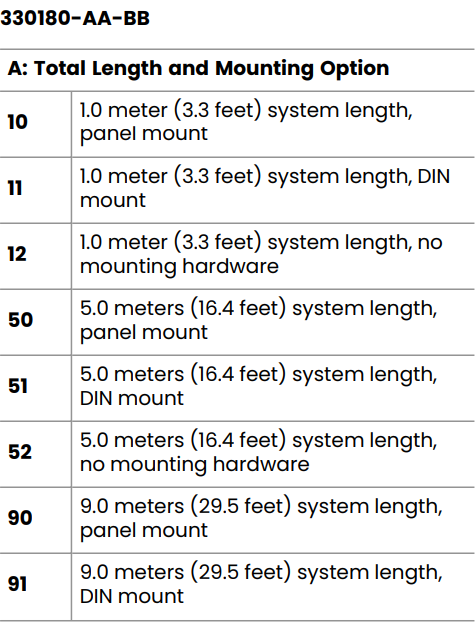

Supports both panel mount and DIN rail mount configurations. The mounting base provides built-in electrical isolation, eliminating the need for separate isolator plates. Its physical structure is compatible with earlier Proximitor sensors, allowing the use of existing four-hole mounting patterns.

Reliable Connection Design

Utilizes SpringLoc terminal strips, enabling secure field wiring connections without special tools and preventing loosening due to vibration. All connectors are gold-plated ClickLoc type, which lock securely with finger-tightening and feature a anti-loosening mechanism.

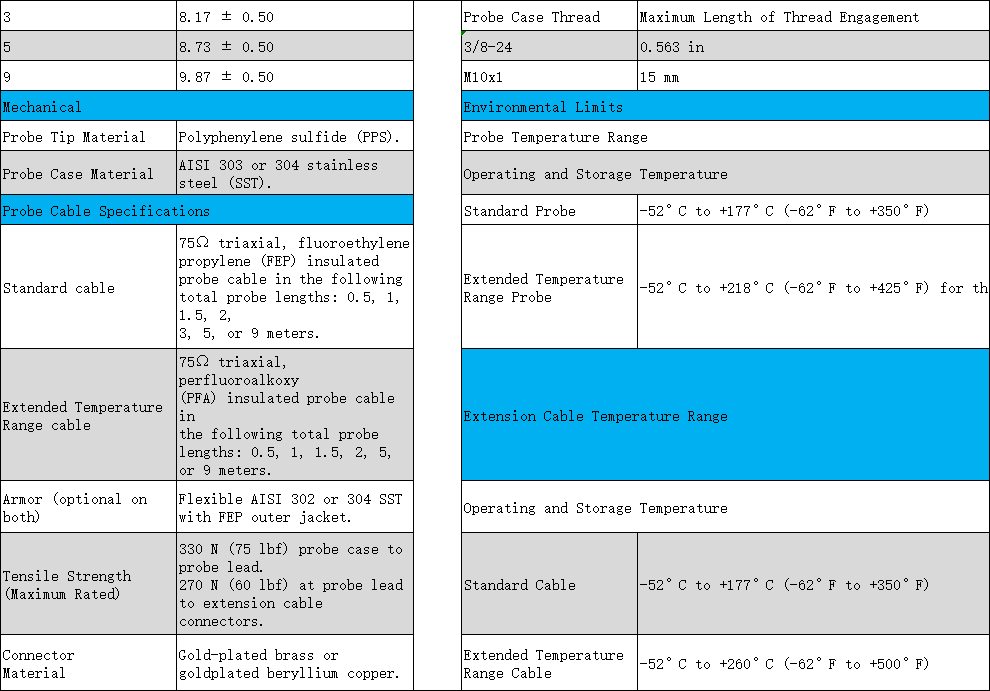

Wide Operating Temperature Range

The standard sensor operating temperature range is -52°C to +100°C, with a storage temperature range of -52°C to +105°C. It can be used with extended temperature range (ETR) probes and cables to suit high-temperature environments.

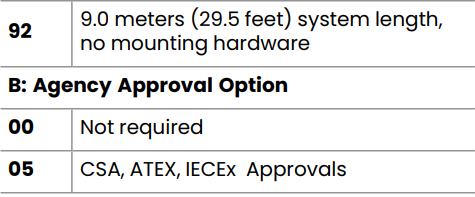

Compliance with Multiple Certifications

Certified by FCC, EMC, RoHS, ATEX, IECEx, CSA, and others, making it suitable for use in hazardous areas (e.g., Class I Zone 2, Division 2). Supports Functional Safety levels SIL 2 (HFT=0) and SIL 3 (HFT=1).

III. Working Principle

Eddy Current Sensing Principle

The 3300 XL Proximitor Sensor operates based on the eddy current effect. The system's 8 mm proximity probe contains a coil. When energized with high-frequency alternating current, it generates an alternating electromagnetic field at the probe tip. When this field approaches a conductive target (e.g., a steel shaft), it induces eddy currents on the target surface. These eddy currents generate an opposing magnetic field, which interacts with the probe's original field, causing a change in the effective impedance of the probe coil.

Signal Conversion and Processing

The core function of the Proximitor Sensor is to detect changes in the probe coil's impedance and convert them into a voltage signal proportional to distance. The specific process is as follows:

Oscillator Drive: An internal oscillator supplies a high-frequency excitation signal (typically 1–2 MHz) to the probe.

Impedance Detection: The impedance of the probe coil changes as the distance between the target and the probe varies.

Demodulation and Amplification: The sensor demodulates the return signal, extracts the distance-related voltage component, and amplifies it to a standard voltage output (typically -1 V to -17 V).

Linearized Output: The system exhibits good linearity over a range of 0.25 mm to 2.3 mm (10–90 mils). The output voltage is directly proportional to distance, with a typical sensitivity of 7.87 V/mm (200 mV/mil).

Static and Dynamic Measurement

Static Position Measurement: The DC output voltage reflects the average distance between the probe and the target, used for monitoring axial displacement, bearing clearance, etc.

Dynamic Vibration Measurement: The AC component of the output voltage reflects the target's vibration amplitude and frequency, used for analyzing mechanical vibration conditions.

Temperature Compensation and Stability

The sensor's internal circuitry includes temperature compensation, ensuring output stability over a range of -35°C to +65°C. The output is minimally affected by power supply fluctuations, with a supply sensitivity of less than 2 mV/V.

System Integration and Calibration

The sensor is factory-calibrated for AISI 4140 steel targets. Calibration for other target materials is available upon request. The system supports full component interchangeability, eliminating the need for field recalibration and greatly simplifying installation and maintenance procedures.

IV. Expanded Application Scenarios

The primary applications of the 3300 XL Proximity Transducer System include:

Vibration Monitoring on Fluid-Film Bearing Machines:

Measured Parameter: Radial vibration amplitude.

Typical Machinery: Steam turbines, compressors, gas turbines, pumps, fans.

Installation Requirement: Probe mounted perpendicular to the shaft surface, gap set to the center of the linear range (recommended 1.27 mm / 50 mils, output approx. -9 Vdc).

Axial and Radial Position Measurement:

Measured Parameters: Axial shaft displacement (thrust bearing wear), radial relative position (eccentricity).

Installation Requirement: Typically requires pairs for axial measurement or orthogonal pairs (X & Y directions) for radial measurement to capture complete motion trajectory.

Keyphasor® Reference Signal:

Function: Provides a benchmark signal for speed measurement and vibration phase analysis. Generates a pulse voltage signal once per shaft revolution.

Application: Used for synchronous data acquisition, phase analysis, order tracking, and startup/shutdown analysis.

Overspeed Protection and Speed Measurement:

Note: When considering this transducer system for overspeed protection applications, it is essential to consult the Bently Nevada Applications Note, Considerations when using Eddy Current Proximity Probes for Overspeed Protection Applications, to ensure the system design meets safety integrity requirements.

V. Environmental Adaptability and Robustness Design

Temperature Performance:

Standard System: Over a probe temperature range of -35°C to +120°C with the Proximitor sensor and extension cable between 0°C to +45°C, the ISF remains within ±10% and the DSL remains within ±0.076 mm (±3 mils), demonstrating excellent temperature stability.

Extended Temperature Range (ETR) System: When using ETR probes and ETR extension cables, the system can operate with probe and cable temperatures up to +260°C, providing a solution for high-temperature applications (e.g., gas turbine exhaust end).

Electromagnetic Interference Immunity:

As mentioned, its excellent RFI/EMI immunity allows it to adapt to complex industrial electromagnetic environments. Specific data indicates minimal output variation in a 60 Hz, 300 Gauss magnetic field (e.g., for a 5-meter sensor at a 50 mil gap, output change is approximately 0.0131 mil-pp/Gauss).

Physical Robustness:

System components feature rugged design. Probes incorporate patented TipLoc and CableLoc technologies, ensuring a robust bond between the probe tip and body, with cable pull strength of 330 N (75 lbf).

The FluidLoc cable option prevents oil and other liquids from leaking out of the machine through the cable's interior, suitable for environments with high lubricating oil pressure.

VI. System Integration and Commissioning Key Points

Calibration and Target Material:

The sensor is factory-calibrated for AISI 4140 steel. If measuring other materials (e.g., stainless steel, titanium alloy), the sensitivity will change, and a special factory calibration request is necessary.

System Length and Configuration:

The total system length (probe cable + extension cable) must match the nominal length of the Proximitor Sensor (1 meter, 5 meters, or 9 meters). For example, a 5-meter system is typically composed of a 1-meter probe + 4-meter extension cable, or a 0.5-meter probe + 4.5-meter extension cable, etc.

Installation and Wiring Specifications:

Probe Installation: Pay attention to the maximum thread engagement length (e.g., 0.563 inches for 3/8-24 thread). Exceeding this may cause binding.

Field Wiring: It is recommended to use 0.2 to 1.5 mm² (16-24 AWG) 3-conductor shielded cable, with a maximum length of 305 meters. Long cables will cause attenuation of the high-frequency signal response (refer to the Frequency Response graphs in the datasheet).

Connection Protection: It is strongly recommended to use connector protectors or silicone self-fusing tape at all connection points to prevent contamination by oil, moisture, and dust, ensuring long-term connection reliability.

Safety and Responsibility:

The probe is designed to seal differential pressure, but its Viton® O-ring is not absolutely reliable under all conditions. It is the customer's/user's responsibility to ensure all liquids and gases are contained safely should leakage occur from a proximity probe. Bently Nevada is not responsible for any damages resulting from leaking 3300 XL 8 mm proximity probes, and probes damaged due to leakage are not replaced under warranty.