| General |

|

| Product Name | IS220PPDAH1A Power Diagnostic I/O Pack |

| Target System | Mark VIe, Mark VIeS Control Systems |

| Primary Function | Power Distribution System Feedback and Monitoring |

| Electrical Characteristics |

|

| Operating Voltage | 28 V DC ±5% (Supplied by host board via DC-62 connector) |

| Typical Power Consumption | 5.3 W |

| Worst-Case Power Consumption | 6.2 W |

| Power Protection | Hosted by a polysilicon self-resetting fuse on the host board (rated 0.5A @ 20°C, derated to 0.28A @ 70°C). |

| Analog Input Channels | Up to 30 single-ended inputs (6 feedback groups x 5 channels per group) |

| Analog Input Resolution | 16-bit Analog-to-Digital Converter (ADC) |

| Input Sensing Method | Differential measurement relative to the group's Fdbk_Ground reference. |

| ID Lines | 2 lines per feedback group (signal and ground) for electronic board identification. |

| Communication Interface | 2 x 10/100 Mbps Ethernet ports (RJ-45), dual-redundant IONet connection. |

| Input/Feedback Compatibility |

|

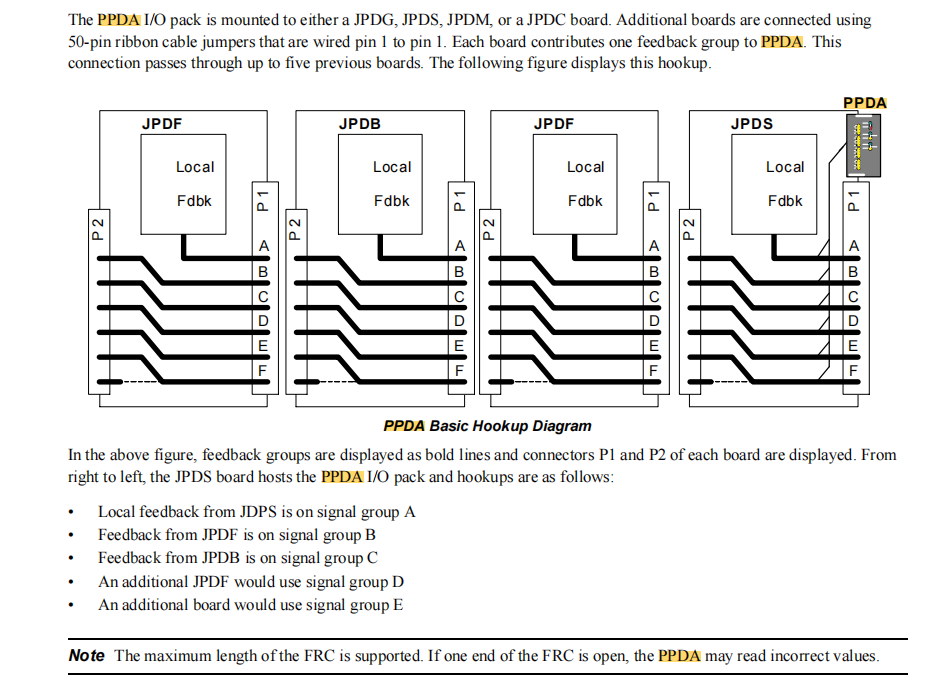

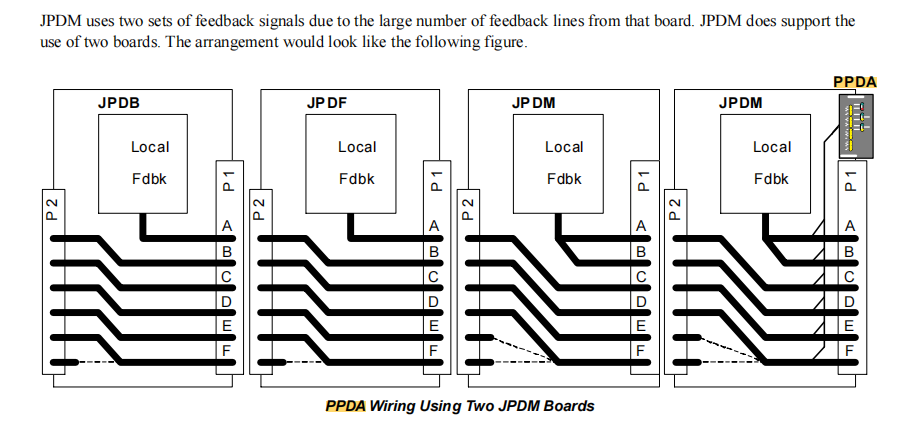

| Host Boards (with PPDA) | JPDS, JPDM, JPDG, JPDC |

| Compatible Feedback Boards | JPDB (AC), JPDE (24/48V DC), JPDF (125V DC) |

| Maximum Number of Boards | Supports up to 6 feedback groups in total. The actual number of connected boards depends on the host type:

- JPDS Host: +5 auxiliary boards (uses 1 group)

- JPDM Host: +4 auxiliary boards (uses 2 groups)

- JPDC Host: +4 auxiliary boards (uses 2 groups)

- JPDG Host: +3 auxiliary boards (uses 3 groups) |

| Physical & Mechanical |

|

| Dimensions (H x W x D) | 8.26 cm x 4.19 cm x 12.1 cm (3.25 in x 1.65 in x 4.78 in) |

| Primary Connector | 62-pin D-Sub (DC-62) to host board (power, feedback, ID). |

| Communication Connectors | 2 x Ethernet RJ-45. |

| Mounting | Plugs directly into the host board's JA1 connector and is secured with an angle bracket and nuts onto fixed studs. |

| Technology | Surface Mount Technology (SMT) |

| Environmental |

|

| Operating Temperature | PPDA H1A: -30°C to +65°C (-22°F to +149°F) |

| Storage Temperature | -40°C to +85°C (-40°F to +185°F) |

| Relative Humidity | 5% to 95%, non-condensing |

| Altitude | Rated for operation up to 2000 meters. |

| Pollution Degree | Designed for Pollution Degree 2 environments (per IEC 60664-1). |

| Diagnostics & Indicators |

|

| LED Indicators | 24 front-panel LEDs (23 Yellow, 1 Red "Fault" LED). |

| Key LED Functions | Pbus R/S/T Regulation, R/S/T Source OK, 125V/24V Battery Volts & Grounding, AC Input 1/2 OK, Aux Outputs OK, Application-driven (x4). |

| Self-Diagnostics | Power-up self-test (RAM, Flash, Ethernet, hardware), continuous internal power supply monitoring, analog input circuit validation via precision references. |

| Software & Configuration |

|

| Configuration Software | GE ToolboxST |

| Minimum Software Version | ControlST V04.07. Note: Accelerometer feature is no longer supported starting with ControlST V05.02. |

| Configuration Parameters | Includes PS28vEnable, InputDiagEnab, DC_125v_Trig_Volt, Gnd_Mag_Trig_Volt, ACFdbkInVoltage, FuseDiag, etc. |