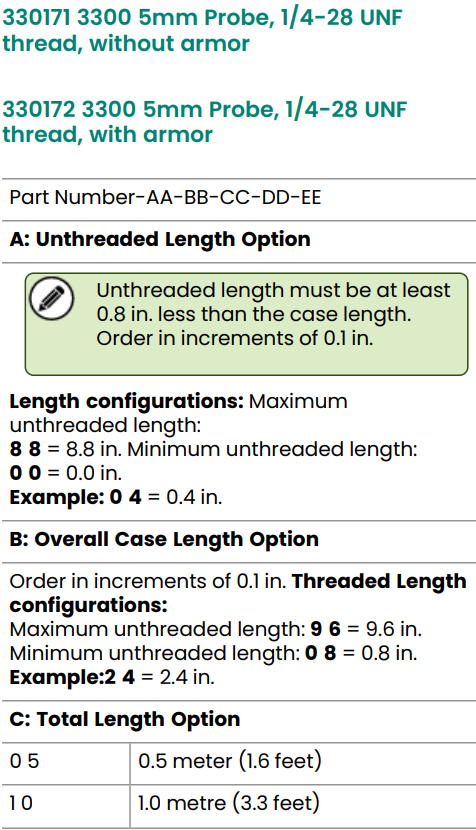

Models 330171 and 330172 are core components of the Bently Nevada 3300 5 mm Proximity Transducer System, representing high-precision, non-contact displacement and vibration sensors. Both models feature a 1/4-28 UNF threaded mounting design. The key distinction lies in their mechanical protection: Model 330171 is the standard non-armored version, while Model 330172 includes a flexible stainless steel armor for enhanced durability in harsh environments subject to physical abuse, abrasion, or where added cable protection is critical.

These probes, when combined with a 3300 XL Extension Cable and a 3300 XL Proximitor Sensor, form a complete 3300 5 mm Proximity Transducer System. This system is extensively used for condition monitoring of rotating machinery, including measurements of vibration, position, Keyphasor signals, and rotational speed.

2. Working Principle: Eddy Current Sensing

The 3300 5 mm Proximity Probe system operates based on the Eddy Current Sensing Principle. Its fundamental operation involves electromagnetically measuring the change in the gap between the probe tip and a conductive target surface. The detailed working principle is as follows:

2.1 Electromagnetic Field Generation and Eddy Current Effect

The probe contains a miniature coil at its tip. When this coil is energized by a high-frequency alternating current (typically supplied by the Proximitor Sensor), it generates a high-frequency alternating electromagnetic field that radiates from the probe tip. When this field is directed towards a conductive material (such as a steel shaft), it induces circulating electrical currents, known as eddy currents, on the surface of the target. These eddy currents, in turn, generate their own opposing magnetic field, the strength of which is inversely proportional to the distance between the probe tip and the target.

2.2 Impedance Change and Signal Conversion

The interaction between the probe's magnetic field and the counter-field generated by the eddy currents causes a change in the effective impedance of the probe coil. As the gap decreases, the eddy current effect intensifies, leading to a more significant and measurable change in the coil's impedance. The connected 3300 XL Proximitor Sensor is precisely designed to detect this change in impedance. It conditions the signal and converts it into a DC voltage output that is directly proportional to the gap distance. This system is capable of measuring both static (position) and dynamic (vibration) changes, offering high accuracy and a broad frequency response suitable for most machinery monitoring applications.

2.3 Linear Range and Calibration

The system's effective linear measurement range is from 0.25 mm to 2.3 mm (10 to 90 mils). The recommended gap setting for optimal operation is 1.27 mm (50 mils). Within the linear range, the relationship between the output voltage and the gap distance remains highly linear. The Incremental Scale Factor is typically 7.87 V/mm (200 mV/mil) with a tolerance of ±6.5%, which includes errors from component interchangeability. The Deviation from the Best Fit Straight Line (DSL) is typically better than ±0.038 mm (±1.5 mils). Probes are factory-calibrated by default for AISI 4140 steel targets, but calibration for other materials is available upon request.

3. System Components and Integration

The 3300 5 mm Transducer System functions as an integrated unit comprising three main parts:

The 3300 5 mm Proximity Probe (Models 330171/330172)

The 3300 XL Extension Cable

The 3300 XL Proximitor Sensor

A key advantage of this system is the complete interchangeability of probes, extension cables, and Proximitor sensors. This eliminates the need for time-consuming and costly individual component matching or bench calibration, simplifying spares management and field replacements.

4. Structural Features and Mechanical Design

4.1 Probe Construction and Materials

Probe Tip Material: Polyphenylene Sulfide (PPS), offering excellent resistance to high temperatures, chemicals, and wear.

Probe Case Material: AISI 303 or 304 Stainless Steel, providing high strength and corrosion resistance.

Probe Cable: A 75 Ω triaxial cable with Fluoroethylene Propylene (FEP) insulation. The FluidLoc cable option is available to prevent oil and other liquids from migrating along the cable's interior.

4.2 Connector Design

Features corrosion-resistant, gold-plated brass ClickLoc connectors.

They require only finger-tightening torque to secure (a distinct 'click' confirms engagement), and a specially engineered locking mechanism prevents loosening under vibration.

Connector protectors are highly recommended for all installations and can be ordered pre-installed or separately. They provide superior environmental sealing and mechanical protection for the connection point.

4.3 Armored vs. Non-Armored Versions

Model 330172 (Armored): The cable is protected by a flexible armor braid made of AISI 302 or 304 SST with an FEP outer jacket. This version is designed for applications where the cable is exposed to potential crushing, abrasion, or other physical damage.

Model 330171 (Non-Armored): Suitable for general industrial environments where such physical risks are minimized, offering a more flexible and cost-effective solution.

5. Electrical Performance and Environmental Specifications

5.1 Electrical Parameters

Power Supply Requirement: +17.5 Vdc to +26 Vdc, with a maximum current consumption of 12 mA.

Output Resistance: 50 Ω.

Supply Sensitivity: Less than 2 mV change in output per volt change in supply voltage.

Frequency Response: 0 to 10 kHz (+0, -3 dB), capable of capturing a wide range of vibration phenomena in rotating machinery.

Immunity to Magnetic Fields: The output is minimally affected by 60 Hz magnetic fields up to 300 Gauss, as detailed in the datasheet.

5.2 Temperature Ranges

Probe Operating Temperature: -35°C to +177°C (-31°F to +351°F). Exposure below -34°C may compromise the pressure seal.

Extension Cable Operating Temperature: -51°C to +177°C (-60°F to +351°F) for standard cables.

5.3 Certifications and Approvals

The system complies with CE marking requirements.

It holds various Hazardous Area Approvals such as ATEX and IECEx for use in Zone 0, 1, and 2 classified areas, often requiring connection to appropriate intrinsic safety barriers or galvanic isolators.

Compliant with the RoHS Directive.

6. Application Scenarios and Installation Guidelines

6.1 Typical Applications

Vibration Monitoring on fluid-film bearing machines (e.g., turbines, compressors, pumps).

Radial and Axial Position measurement.

Keyphasor and Speed measurement applications. (Consult Bently Nevada for specific over-speed protection application notes).

Predictive maintenance on critical equipment like generators and large electric motors.

6.2 Installation Considerations

Minimum Target Size: 15.2 mm (0.6 inches) diameter for a flat target.

Shaft Diameter: Minimum 50.8 mm (2 inches), with a recommended minimum of 76.2 mm (3 inches) to minimize scale factor changes.

Probe Tip Separation: To limit electrical cross-talk between two systems to less than 50 mV, maintain a minimum tip-to-tip separation of:

Thread Engagement: Adhere to maximum thread engagement limits (0.375 in for 1/4-28) to prevent binding.

Cable Bend Radius: Maintain a minimum bend radius of 25.4 mm (1.0 in) to avoid cable damage.

7. Key Product Advantages Summary

Full Interchangeability: No need for system recalibration when replacing probes, cables, or Proximitors.

High Accuracy and Stability: Maintains a stable linear output across a wide temperature range.

Enhanced Mechanical Robustness: The patented Tiploc molding process creates a stronger bond between the probe tip and body.

Superior Environmental Protection: Options like FluidLoc cables, connector protectors, and armored constructions cater to challenging environments.

Safety and Compliance: Certified for use in hazardous areas and complies with major international standards.