The IS220PSCAH1B, designated as a PSCA Serial Communication I/O pack, is an advanced component within GE's Mark VIe and Mark VIeS control system architecture. While its fundamental purpose is to bridge Ethernet networks and serial devices, its specific implementation and capabilities position it as a critical enabler for modern, integrated industrial control. The module is engineered not merely as an interface, but as an intelligent gateway that consolidates diverse serial communication streams onto the high-speed, deterministic IONet, thereby unifying data acquisition and command dissemination across the control ecosystem. Its role is pivotal in environments requiring robust data ingestion from a multitude of legacy and contemporary serial assets, such as turbine control interfaces, auxiliary system drives, and comprehensive plant monitoring networks.

2. Advanced Hardware Architecture and Component Synergy

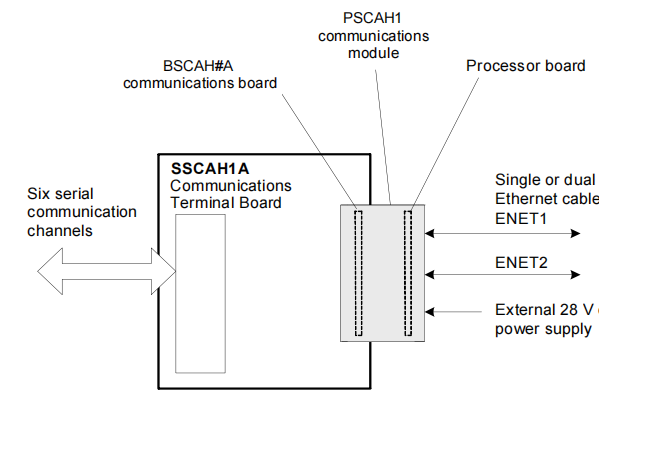

The IS220PSCAH1B's hardware represents an evolution in the PSCA series, built upon a foundation of enhanced processing and seamless integration.

High-Performance Processor Board (BPPC): The defining characteristic of the IS420PSCAH1B is its integration of the BPPC processor board. This board delivers superior computational power necessary for handling concurrent data streams from its six serial channels and one Ethernet Modbus channel. Its functional compatibility is guaranteed in ControlST* V04.07 and later firmware versions, ensuring access to the latest system features and optimizations.

Dedicated Serial Communication Board: This specialized board houses six fully independent serial transceiver channels. Each channel is a self-contained communication engine, capable of being dynamically configured for different electrical standards and protocols without affecting the others.

Robust Physical Interfacing:

Network Uplink: The dual RJ-45 Ethernet ports (ENET1, ENET2) provide a fault-tolerant link to the IONet. The module's firmware intelligently manages these connections, ensuring continuous data flow even in the event of a single network path failure.

Field Device Downlink: The DC-62 pin connector is the critical physical interface to the SSCA terminal board. This direct-plug connection ensures signal integrity for all serial channels and receives power.

Serviceability Features: The inclusion of threaded inserts for mechanical securing prevents connector strain, and the hot-swappable power input with soft-start capability underscores a design philosophy centered on high system availability and ease of maintenance.

3. Core Functional Capabilities and Operational Principles

The IS220PSCAH1B's operational intelligence lies in its ability to manage multiple, complex data pathways with configurable performance characteristics.

3.1 Advanced Serial Protocol Gateway

The module's six serial channels operate as a versatile protocol gateway. The principle of operation involves real-time signal transformation and packetization. The transceivers on the communication board convert incoming differential (RS-422/485) or single-ended (RS-232) electrical signals into digital data understandable by the BPPC processor. This processor then frames the data according to the configured protocol (e.g., Modbus RTU, Honeywell ST-3000) and prepares it for transmission over the IONet. The reverse process is executed for outgoing commands. The key to its flexibility is the software-defined nature of each channel's physical layer (baud rate, parity, data bits) and data-link layer (protocol handling), which is managed through the ToolboxST* application.

3.2 Hierarchical Data Management and Coherency

The module distinguishes its data handling based on criticality and performance requirements, creating a hierarchical data management system.

Deterministic Fixed I/O Services: For time-sensitive and critical devices, the module reserves specific ports for Fixed I/O services. This includes:

Honeywell ST-3000 Transducer Service (Ports 1 & 2): This service operates on a high-speed, deterministic schedule (375 kbaud). The module actively polls the transducers, and the received data (e.g., pressure, temperature) is processed within a single control frame. It is assigned individual health bits, subjected to system limit checking, and directly mapped into the controller's signal space, making it equivalent to hardwired I/O in terms of reliability and speed.

Kollmorgen Drive Interface (Any 3 Ports): This dedicated service manages communication with the electric drive using a proprietary protocol. The data exchange, including command outputs and status feedback, is handled with high priority to ensure precise motor control.

High-Efficiency Modbus I/O Services: For less time-critical but potentially high-volume data, the module employs its Modbus Master services. The principle here is one of efficiency and scalability. Instead of processing every signal every frame, the module "bundles" register reads and writes for each slave device. These bundles are then transferred as a coherent block to the Mark VIe controller at a user-defined rate (0.5, 1, 2, or 4 Hz). This "Second Class I/O" mechanism conserves network and controller resources. Data coherency is maintained at the individual signal level within its bundle, but not across the entire module. The health of each Modbus point is tracked independently, with a signal being declared unhealthy only after three consecutive communication time-outs.

3.3 Dual-Modality Modbus Master Implementation

The IS220PSCAH1B excels as a unified Modbus Master, offering two distinct transport mechanisms.

Serial Modbus Master (Ports 1-6): This service transforms traditional serial lines into extensions of the IONet. It supports a wide array of configurations, including multidrop RS-485 networks with up to 8 devices per port. Its configurability extends to 32-bit data word ordering, which is essential for correctly interpreting floating-point numbers and long integers from modern devices.

Ethernet Modbus TCP Master (Port 7): Leveraging one of its Ethernet ports on a simplex network, the module can directly communicate with Ethernet-enabled PLCs, HMIs, and other devices. It adheres to the Open Modbus/TCP specification. A sophisticated connection management system is employed, featuring configurable read time-outs and automatic reconnection attempts (every 10 seconds) to handle network or slave device interruptions, thus enhancing communication resilience.

4. Enhanced Diagnostics and Proactive System Health Monitoring

The diagnostic suite in the IS220PSCAH1B is designed for proactive maintenance. Beyond standard power-up self-tests (RAM, Flash, Ethernet PHY), it performs continuous monitoring of power supply integrity and hardware-software compatibility checks via electronic ID lines. For analog Fixed I/O, it executes real-time system limit checks. All diagnostic events can be configured as latched or non-latched and are easily accessible and resettable through the ToolboxST* application, providing a clear window into the module's and the connected field devices' health.

5. Detailed Comparison: IS220PSCAH1B vs. IS220PSCAH1A

The IS220PSCAH1B and IS220PSCAH1A, while belonging to the same PSCA family, possess distinct characteristics that make them suitable for different application requirements and system generations.

| Feature | IS220PSCAH1B (PSCAH1B) | IS220PSCAH1A (PSCAH1A) |

| 1. Processor Board | BPPC. This is a functionally compatible but more advanced processor, offering potentially enhanced processing speed and memory resources for handling complex or numerous communication tasks. | BPPB. The standard processor board for the earlier generation of this I/O pack. |

| 2. Firmware & Software Compatibility | Requires ControlST* V04.07 or later. It is integrated into the newer software ecosystem of the Mark VIeS system. | Compatible with earlier versions of ControlST*, predating V04.07. Represents the legacy software branch. |

| 3. Ambient Temperature Rating | Wider Range: -40°C to +70°C. This makes it suitable for more extreme industrial environments, such as outdoor installations or harsh factory floors. | Standard Range: -30°C to +65°C. Sufficient for most controlled industrial settings but with less margin for extreme conditions. |

| 4. System Architecture Perspective | Presented as an integral component for systems utilizing the enhanced capabilities of the BPPC processor series, often associated with the Mark VIeS platform. It embodies the evolution of the distributed I/O concept. | Represents the foundational implementation of the PSCA functionality within the standard Mark VIe control system architecture. |

| 5. Functional Focus | The description emphasizes its role in handling concurrent data streams and its operation within a fault-tolerant network, highlighting its suitability for complex, high-availability systems. | The focus is on providing core serial communication bridging capabilities, establishing the essential link between IONet and serial devices. |

| 6. Diagnostic Emphasis | The diagnostics are framed within the context of proactive system health monitoring and resilience, aligning with its role in critical, modern control systems. | Diagnostics are described as a standard, reliable self-test and monitoring feature, ensuring basic operational integrity. |