The CA202 piezoelectric accelerometer is a flagship industrial vibration sensor from Meggitt Sensing Systems' vibro-meter brand, designed for high-precision, highly reliable, long-term continuous monitoring in extremely harsh industrial environments and potentially explosive hazardous areas. This report details model 144-202-000-126, which is the Intrinsic Safety (Ex ia) certified version equipped with an 11-meter integral cable. This model is particularly suitable for applications requiring longer signal transmission distances in locations classified as Zone 0, 1, or 2 hazardous areas, such as vibration monitoring of critical rotating machinery in petrochemical plants, natural gas compressor stations, offshore platforms, and mining.

The sensor utilizes an advanced shear-mode polycrystalline piezoelectric sensing element with full internal case isolation, ensuring excellent signal symmetry, extremely low transverse sensitivity, and high immunity to ground loop interference. Its signature feature is the fully hermetic welding of the sensor's austenitic stainless steel case to a high-temperature resistant stainless steel protection hose, forming a robust, leak-proof monolithic unit. This construction withstands long-term exposure to complex industrial contaminants such as 100% humidity, high-pressure steam, lubricating oil, corrosive chemicals, salt spray, and dust.

As the core sensing component of industrial predictive maintenance systems, the CA202-126 works in concert with vibro-meter® charge amplifiers (e.g., IPC704/705), galvanic isolation modules (GSI series), and upper-level intelligent monitoring systems (e.g., VM600) to form a complete vibration measurement chain—from signal sensing, conditioning, and transmission to analysis and decision-making. It provides the indispensable data foundation for ensuring the safe, stable, and long-term operation of major industrial assets.

2. Core Advantages and Value Proposition

Exceptional Environmental Tolerance and Reliability:

Extreme Temperature Range: The sensing head operates from -55°C to +260°C, allowing it to be mounted directly on hot spots like gas turbine exhaust ducts or high-temperature pump casings without complex cooling arrangements.

Monolithic Sealed Fortress: The fully welded seal from the sensing head to the cable exit provides a protection level surpassing traditional connector-based sensors, completely eliminating internal short circuits or performance degradation due to joint leakage, resulting in lower lifecycle costs.

Superior Measurement Performance and Signal Fidelity:

High Signal-to-Noise Ratio Foundation: High sensitivity of 100 pC/g, combined with low-noise coaxial cable, enables precise capture of weak early-stage fault vibration signatures.

Wide Bandwidth and High Linearity: A flat frequency response from 0.5 Hz to 6 kHz (±5%) and a wide dynamic range up to 400g ensure the ability to monitor both low-speed shaft fundamental frequencies and high-frequency components like gear mesh or blade pass. Linearity error is less than ±1%.

Excellent Anti-Interference Capability: Symmetrical differential output and internal insulation design effectively suppress common-mode interference. An insulation resistance of 10^9 Ω significantly reduces signal leakage risk.

Authoritative Safety Certification for Hazardous Areas: Model 144-202-000-126 has obtained Intrinsic Safety (Ex ia IIC) certifications covering major global markets, including EU ATEX, International IECEx, UK UKEX, Korea KGS, and Russia EAC. This ensures the product can be safely used even in the most hazardous environments containing Group IIB+C explosive gases (Zone 0), providing a solid guarantee for project compliance and safe production.

Convenient Engineering Deployment and Maintenance-Free Design:

Pre-Installed Long Cable: The 11-meter integral cable offers ample installation flexibility, facilitating routing around obstacles in complex layouts and placement of the charge amplifier in more serviceable locations.

Precision from Factory: Each sensor is dynamically calibrated under standard conditions (5g, 120Hz) with calibration data provided, enabling plug-and-play operation and greatly simplifying on-site commissioning.

Robust Mechanical Construction: Heavy-duty housing and armored cable designed for industrial environments withstand installation stresses and continuous operational vibration.

3. Working Principle and Technical Explanation

The CA202 is a high-impedance charge output piezoelectric accelerometer. Its core sensing element is specially polarized polycrystalline piezoelectric ceramic material operating in shear mode. When subjected to axial vibration, a tightly coupled seismic mass applies a shear force to the piezoelectric crystal, causing it to deform.

Based on the piezoelectric effect, polarization occurs within the crystal, generating a charge quantity (Q) proportional to the applied mechanical stress (i.e., acceleration) on its two electrode faces. This relationship can be simplified as: Q = S * a, where S is the charge sensitivity (pC/g) and *a* is the vibration acceleration (g). This charge signal has high impedance characteristics and is highly susceptible to interference from cable movement, connector resistance, and electromagnetic fields.

Therefore, a dedicated charge amplifier (e.g., IPC70x) must be used for local signal conditioning. The charge amplifier is essentially a high-gain, high-input-impedance operational amplifier circuit. Its core function is to convert the weak charge signal into a low-impedance voltage or current signal. Vibro-meter® employs advanced 2-wire current modulation technology: the charge amplifier outputs a 4-20 mA current loop signal proportional to the input charge (i.e., vibration level). This technology offers significant advantages:

Superior Noise Immunity: Current signals are insensitive to transmission line resistance and less susceptible to electromagnetic noise along the path.

Long-Distance Transmission: Enables distortion-free transmission over 1000 meters using ordinary twisted-pair shielded cable.

Combined Power & Signal: Two wires simultaneously provide power to the front-end sensor-amplifier and return the signal, simplifying wiring.

Finally, the current signal is received by a remote galvanic isolation barrier (GSI series), which provides intrinsically safe power limitation for the loop and converts the current signal into a standard voltage signal readable by DCS, PLC, or vibration monitoring systems, completing the full conversion from physical vibration to digital information.

The deep engineering value of choosing the CA202 (separate conditioner) architecture lies in separating the high-temperature tolerant pure sensing unit from the temperature-sensitive precision electronic circuitry. This allows the sensor to penetrate high-temperature "front lines," while the electronics are housed in a more temperate "rear area," achieving an optimal balance of system performance and reliability.

4. Typical Application Scenarios

With its explosion-proof, high-temperature, corrosion-resistant, and long-cable characteristics, the CA202-126 model is an ideal choice for the following high-risk, high-value industrial sectors:

5. Installation, Connection, and Safety Guidelines

5.1 Installation Planning and Preparation

Compliance Verification: Before installation in a hazardous area, verify that the on-site gas group, temperature class, and product explosion-proof marking (Ex ia IIC T6...T2 Ga) match, and strictly adhere to the "Special Conditions for Safe Use" specified in the product's EC Type Examination Certificate.

Location Selection:

Optimal Measurement Point: On the most rigid part of the bearing housing in the vertical or horizontal direction, as close to the bearing load zone as possible. Avoid mounting on thin-walled covers, welded ribs, or non-load-bearing structures.

Cable Routing Planning: Utilize the 11-meter cable length to plan a routing path away from high-temperature heat sources, rotating parts, and strong EMI sources (e.g., VFD cables, high-current busbars). Allow adequate slack for stress relief.

Mounting Surface Preparation:

Flatness: ≤ 0.01 mm to ensure full contact of the sensor base.

Surface Roughness: Recommend Ra 1.6 μm (Grade N7) or better.

Perpendicularity: The normal of the mounting surface must align with the intended vibration measurement axis. Excessive deviation introduces cosine error.

Cleanliness: Thoroughly remove oil, debris, paint, and oxidation.

5.2 Sensor Mechanical Installation Steps

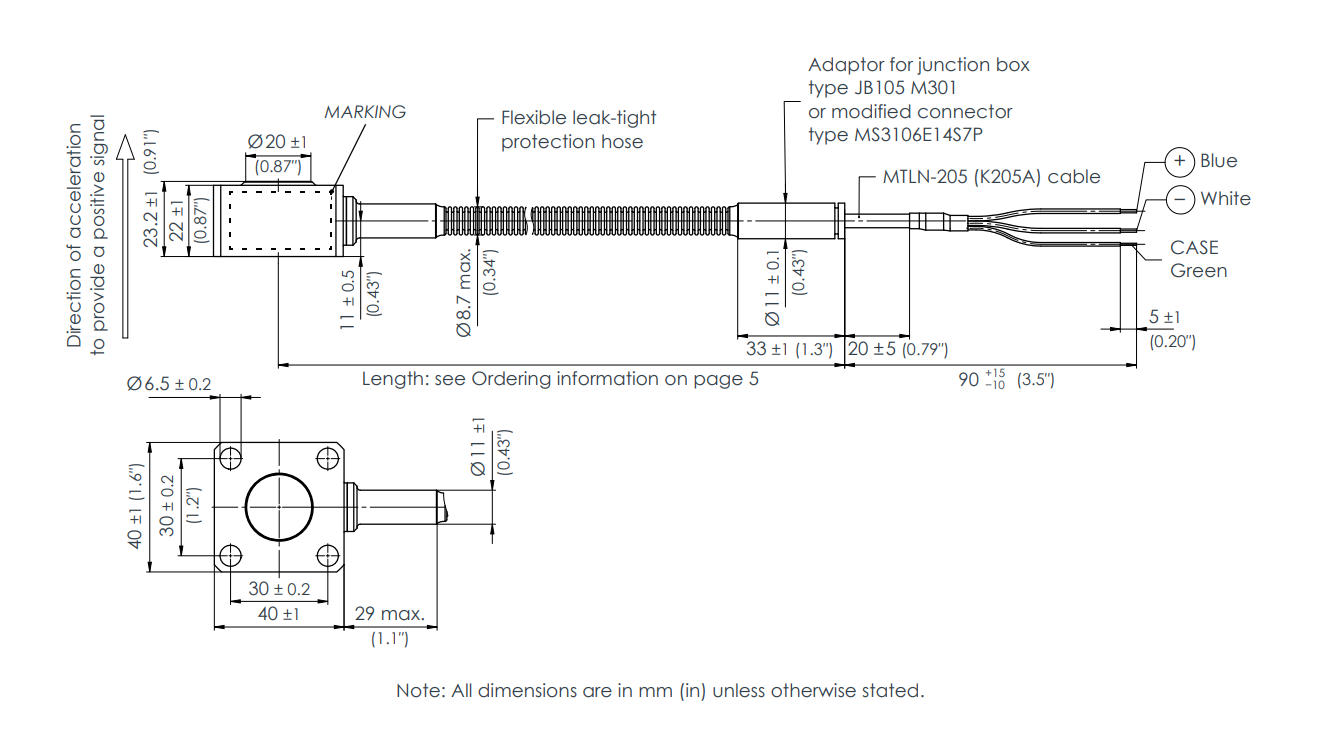

Using the mounting template or drawing, locate and machine 4x M6 tapped holes on the prepared surface to sufficient depth for thread engagement.

Apply a moderate amount of medium-strength thread-locking adhesive (e.g., Loctite 241) to the threads of the screws (M6x35).

Position the sensor, place spring lock washers, and insert the screws.

Using a calibrated torque wrench, tighten all four screws evenly in a crisscross pattern in two steps (e.g., first to 10 N·m, then to 15 N·m). Do not use pneumatic or electric tools directly, and never exceed the maximum torque.

5.3 Cable Routing and Fixing (Critical Steps)

Bending Radius: The absolute minimum static bending radius is 50mm. Maintain a larger radius (e.g., 100mm) in areas with dynamic vibration.

Fixing Spacing: Use stainless steel cable clamps (suitable for Φ8-10mm tube) for fixing. Space at 0.5-1 meter intervals on straight runs. Fix on both sides of all bends and connections. Clamps should not compress the cable to the point of deformation.

Stress Relief: At the sensor cable exit, form a natural "drip loop" or "U-bend" as a mechanical strain relief to prevent vibration from being directly transmitted to the weld joint.

Grounding Treatment: The cable shield is typically grounded at a single point, usually at the charge amplifier end. The specific grounding point must follow the complete system wiring diagram. Incorrect multiple grounding points introduce ground loop noise.

5.4 System Electrical Connection

Connect to Charge Amplifier: Correctly connect the CA202's flying leads (typically red-signal, white-signal ground, shield braid) to the designated high-impedance input terminals of the IPC70x charge amplifier. Tighten the amplifier junction box's sealed glands.

Connect Transmission Cable: From the amplifier's current output, connect the two-core shielded transmission cable (e.g., K2XX series) leading to the safe area.

Connect Barrier & System: In the safe-area control cabinet, connect the transmission cable to the intrinsically safe side and the system power/signal acquisition card to the non-intrinsically safe side. Ensure the safety barrier is correctly configured and certified for this loop.

5.5 Safety Warnings

No Live Work: Before performing any wiring or disassembly in a hazardous area, ensure the system is de-energized and safe work procedures are followed.

No Modifications: Do not cut, splice, or alter the length or structure of the sensor's integral cable in any way. This will immediately invalidate the explosion-proof certification and may cause serious safety incidents.

Professional Maintenance: Any fault diagnosis and repair must be performed by trained personnel familiar with explosion-proof regulations or by contacting Meggitt technical support directly.

6. Maintenance, Diagnostics, and After-Sales Service

Preventive Maintenance:

Regular Inspection: Quarterly or semi-annually, check the mechanical security of the sensor and cable for impacts, corrosion, or excessive wear.

Electrical Check: During system shutdowns, measure the sensor's insulation resistance to ground using a megohmmeter (should be in the GΩ range) to check for internal moisture ingress.

Fault Diagnosis: If the monitoring system detects abnormal signals (e.g., no signal, high noise, reading drift), troubleshoot in sequence:

Check if the monitoring system channel is functional.

Check power supply and wiring of the safety barrier and transmission loop.

Check the charge amplifier status indicators and output.

Suspect the sensor itself last. Sensor failure is extremely rare; issues are usually related to installation or wiring.

Calibration Interval: Under normal operating conditions, the CA202 sensor itself does not require periodic calibration. Its piezoelectric properties are extremely stable. Consider returning the sensor to an authorized Meggitt service center for recalibration only after it has experienced extreme overload shock or if comparative testing shows significant deviation.

Technical Support: Meggitt SA provides comprehensive technical support and product lifecycle services. Users can obtain the latest product documentation, certificates, and manuals through its official website and receive application engineering support via local authorized distributors or by contacting the Switzerland headquarters directly.