The VM600 XIO16T Input/Output Module is a critical signal interface component within VM product line, specifically designed to pair with the VM600 series XMx16 extended condition monitoring modules. As the dedicated interface partner for XMx16 processing modules, the XIO16T module handles all analog signal conditioning, protection, and connections with external systems, serving as a vital bridge between the monitoring system and external sensors and control systems.

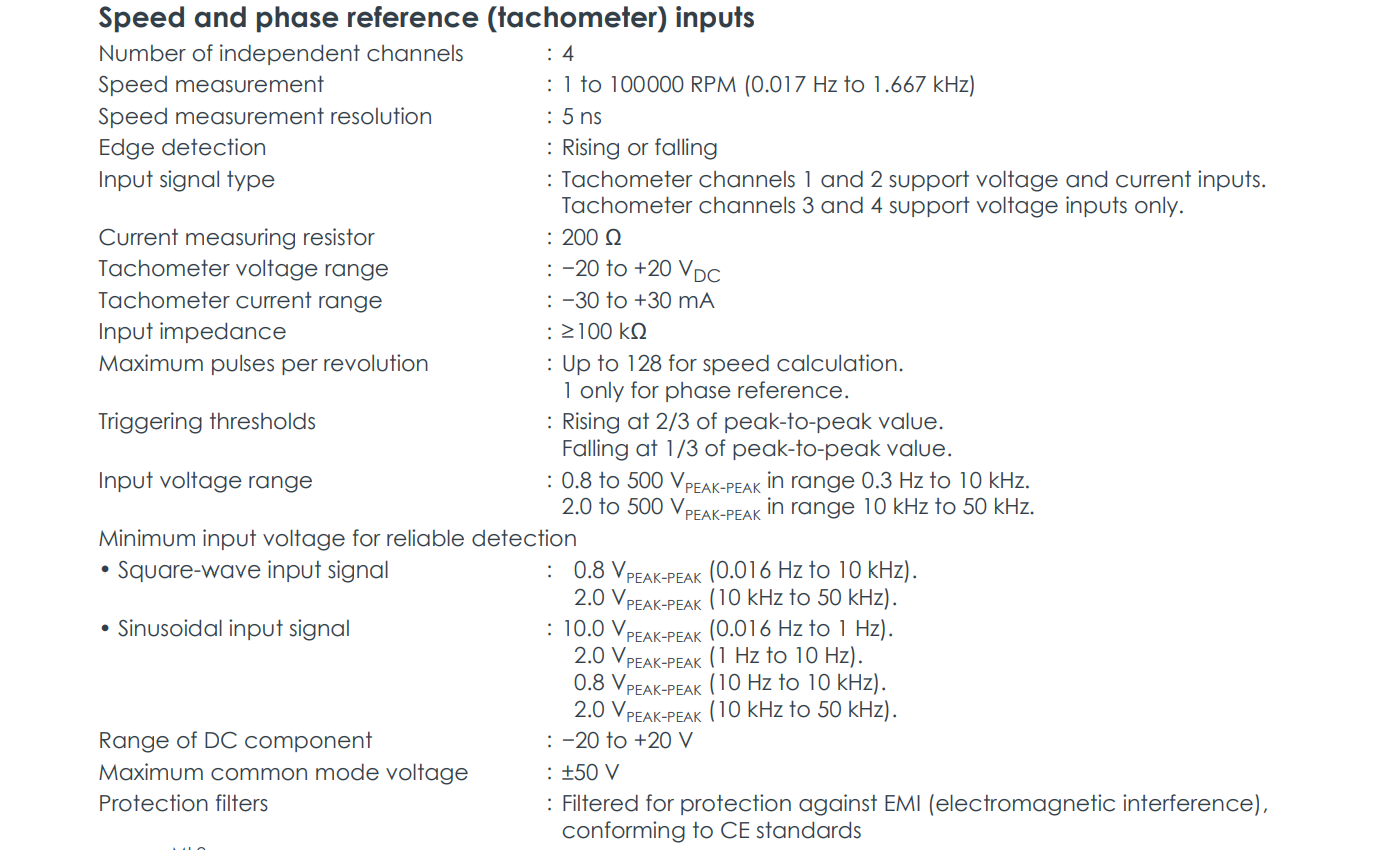

The XIO16T module is installed at the rear of the VM600 rack and connects directly to the rack backplane via two connectors. It provides a complete interface solution for 16 dynamic channels and 4 tachometer channels, supporting various types of sensor signal inputs including acceleration, velocity, displacement vibration signals, as well as speed and phase reference signals. The module employs advanced signal conditioning technology and comprehensive electromagnetic interference protection design to ensure stable and reliable signal transmission in various industrial environments.

This module is an essential component of the VM600 Mk2/VM600 system, particularly suitable for high-performance condition monitoring applications of critical rotating machinery such as steam turbines, gas turbines, hydro turbines, and other high-value rotating equipment. Its robust design, flexible configuration options, and powerful signal processing capabilities make it an ideal choice for industrial condition monitoring applications.

Features & Benefits

1. Comprehensive Signal Interface Capability

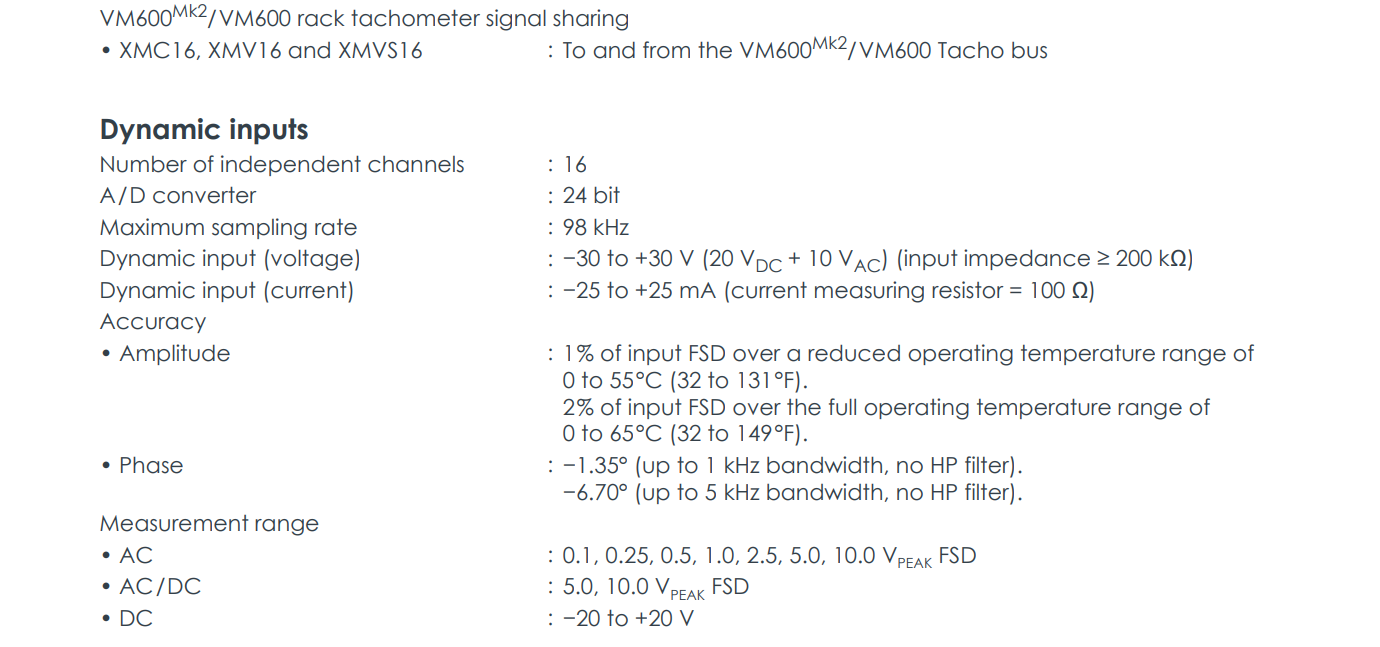

The XIO16T module provides 16 dynamic input channels and 4 tachometer input channels, capable of handling multiple vibration and speed signals simultaneously. All input and output connections are made through removable connectors at the rear of the module, greatly facilitating field wiring. Dynamic input channels support both voltage and current input modes, with voltage range from -30 to +30 V and current range from -25 to +25 mA.

2. Advanced Signal Conditioning Technology

The module incorporates high-performance signal conditioning circuits that preprocess and optimize all input signals. Functions include impedance matching, signal amplification, and filtering, ensuring signals are in optimal condition before being transmitted to the XMx16 processing module. Signal conditioning parameters are fully software-configurable to meet the needs of different application scenarios.

3. Powerful Electromagnetic Interference Protection

All inputs and outputs are protected by carefully designed filtering circuits that effectively suppress electromagnetic interference (EMI) and signal surges, complying with relevant EMC standards. This protection ensures accurate and reliable monitoring data even in harsh industrial electromagnetic environments.

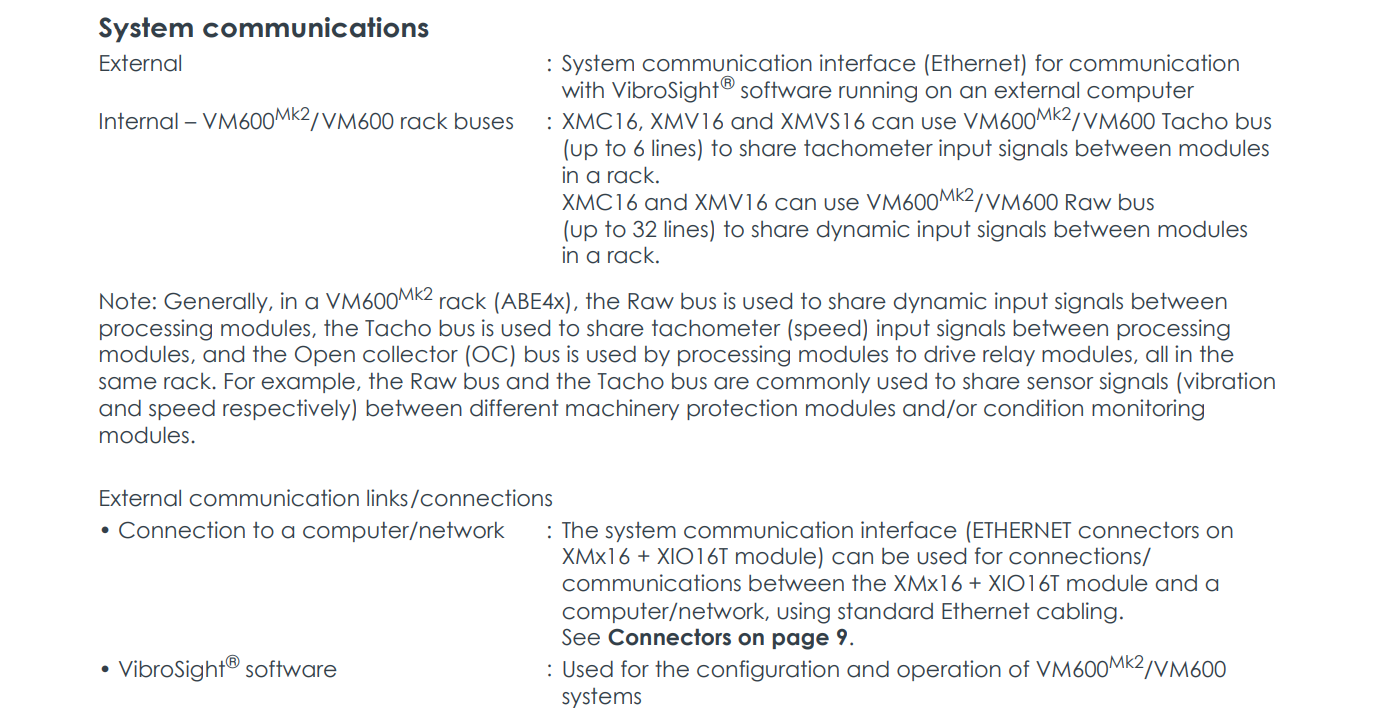

4. Flexible Signal Sharing Support

The XIO16T supports signal sharing within VM600 Mk2/VM600 racks, enabling dynamic input signal sharing via the Raw bus (up to 32 lines) and tachometer input signal sharing via the Tacho bus (up to 6 lines). This design significantly reduces external wiring requirements, simplifies system integration, and improves system reliability and maintainability.

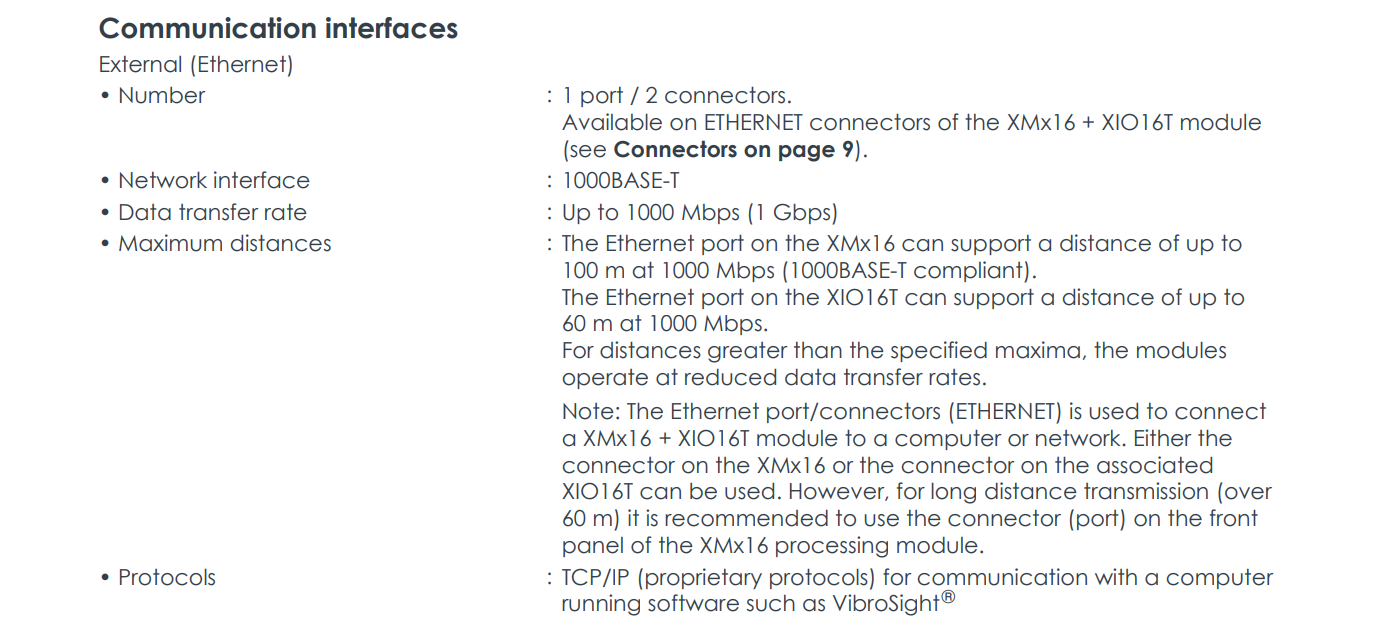

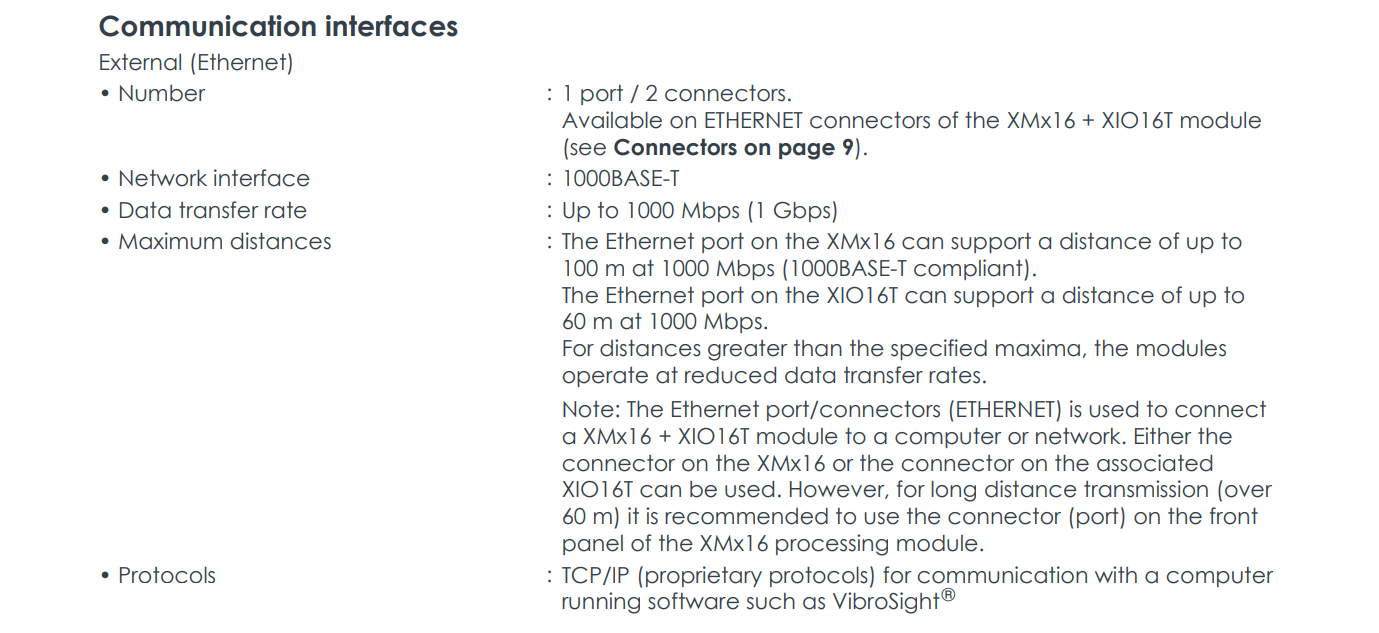

5. Dual Gigabit Ethernet Interfaces

The module provides two Gigabit Ethernet interfaces (one on the front panel and one on the rear panel), supporting data transfer rates up to 1000 Mbps. The front panel interface supports transmission distances up to 100 meters (1000BASE-T compliant), while the rear panel interface supports up to 60 meters. This dual-interface design provides users with flexible connection options.

6. Hot-Swap Capability

Supports live insertion and removal of modules (hot-swappable) without interrupting system operation, significantly enhancing system maintainability and availability. The module features comprehensive status indication functions, with LED indicators displaying the module's operational status and communication status in real-time.

7. Environmental Adaptability Design

Operating temperature range: 0 to 65°C (32 to 149°F)

Storage temperature range: -40 to 85°C (-40 to 185°F)

Operating humidity: 0 to 90% relative humidity (non-condensing)

Excellent environmental adaptability suitable for various industrial environments.

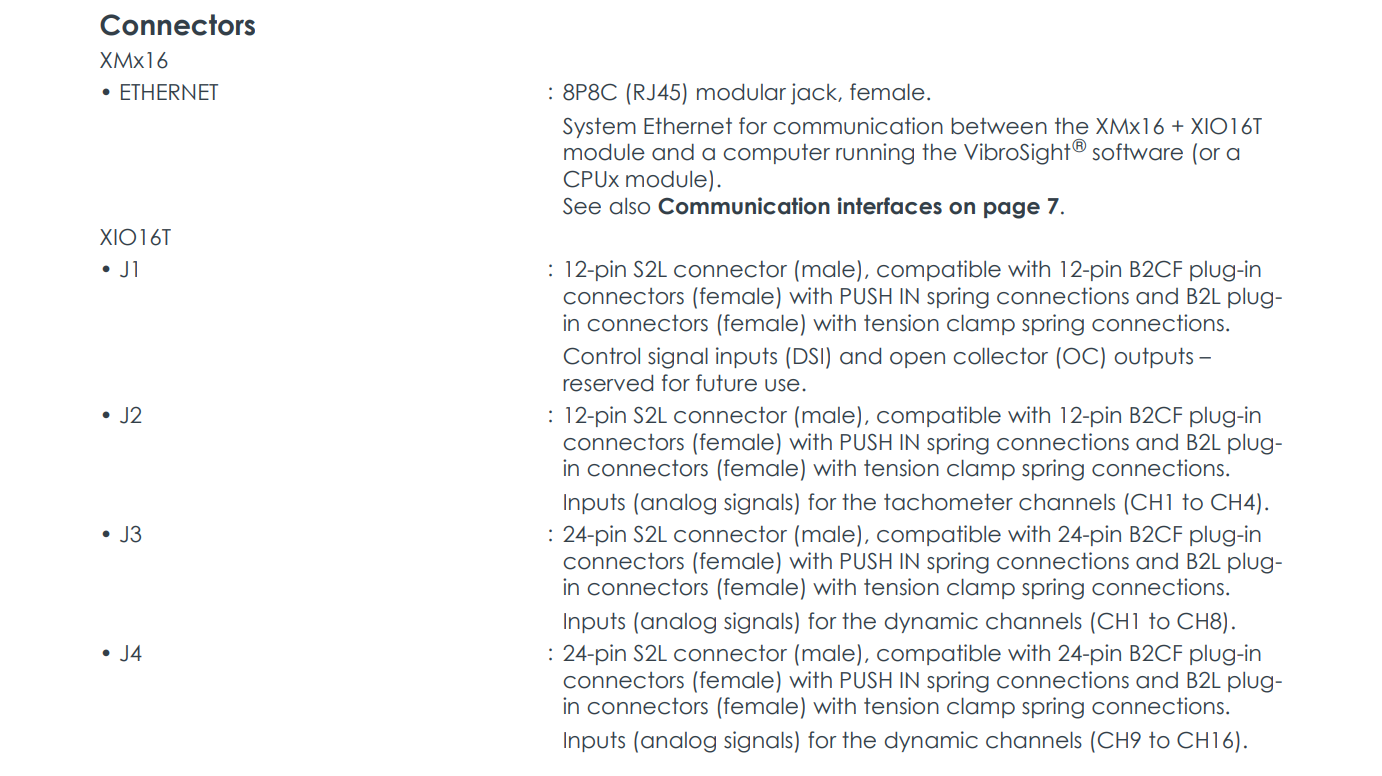

8. Reliable Connection System

Utilizes high-quality connector systems including 12-pin and 24-pin S2L connectors, compatible with B2CF plug-in connectors. All connectors are removable, simplifying installation and maintenance. Dedicated crimp terminals and tools are recommended to ensure connection reliability and consistency.

9. Low-Power Design

The module receives operating power (+5 VDC and ±12 VDC) from the VM600 rack power supply, with total power consumption less than 26 W (combined with XMx16 module). This efficient power design ensures stable module operation and low heat dissipation.

10. Safety Certifications

EAC marked, compliant with TR CU 020/2011 electromagnetic compatibility standards and TR CU 004/2011 electrical safety standards. Certified by the Russian Federal Agency for Technical Regulation and Metrology (Rosstandart) with pattern approval certificate OC.C.28.004.A N° 60224.

Working Principle

The working principle of the VM600 XIO16T Input/Output Module is based on advanced signal conditioning and protection technologies, serving as an intelligent interface between the XMx16 processing module and external sensors and control systems. The working principle can be divided into several key aspects:

1. System Architecture & Signal Flow

The XIO16T module is installed in the rear of the VM600 rack and connects to the XMx16 processing module (installed in the front) via backplane connectors. Sensor signals are input through connectors at the rear of the module, where they undergo signal conditioning and protection before being transmitted to the XMx16 module for digitization and processing via the backplane.

The module employs a distributed processing architecture where the XIO16T handles all analog signal preprocessing, while the XMx16 handles digital signal processing and analysis. This well-defined division of labor leverages their respective strengths, ensuring optimal system performance.

2. Signal Input Processing

Dynamic input signals are input through J3 and J4 connectors (8 channels each, 16 channels total), while tachometer signals are input through the J2 connector (4 channels). All input channels include carefully designed input circuits providing appropriate impedance matching and signal conditioning.

For voltage input signals, the module provides high input impedance (≥200 kΩ), ensuring minimal loading effect on sensor signals. For current input signals, the module uses 100 Ω precision measuring resistors to convert current signals to voltage signals for processing.

3. Signal Conditioning & Protection

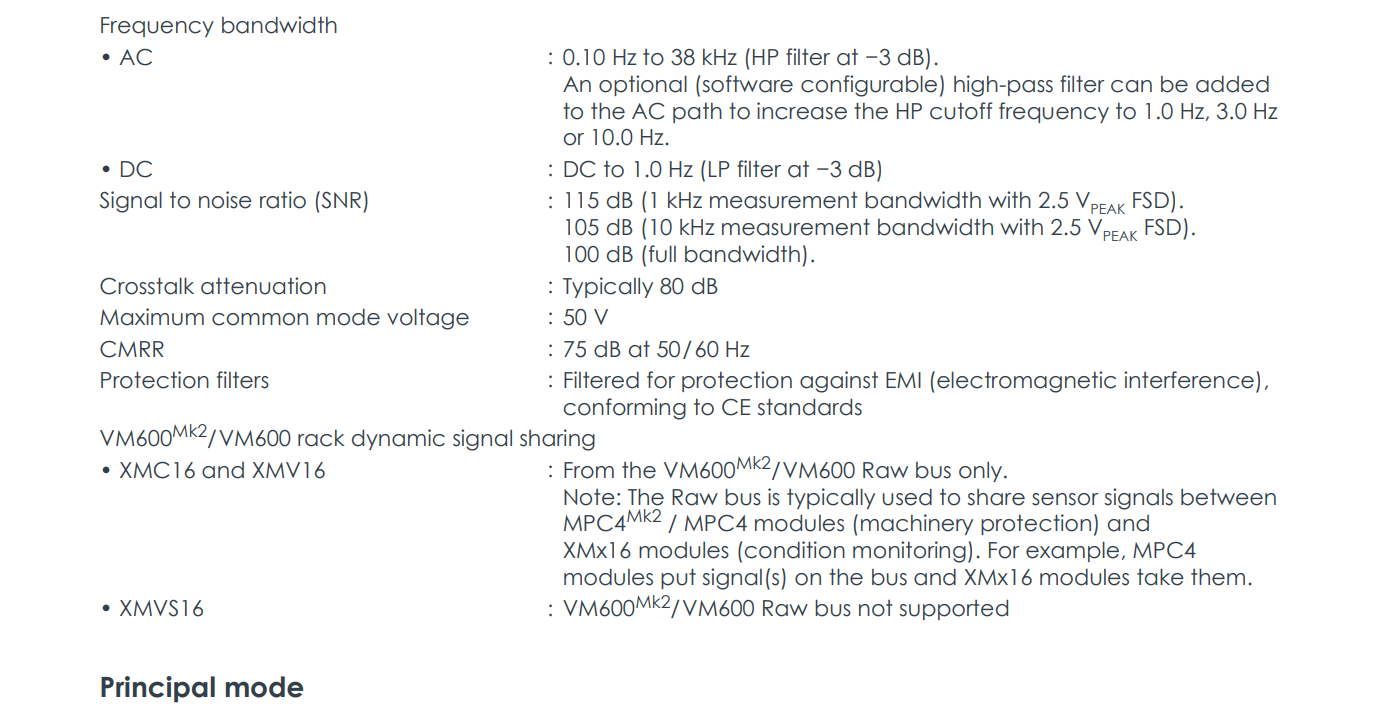

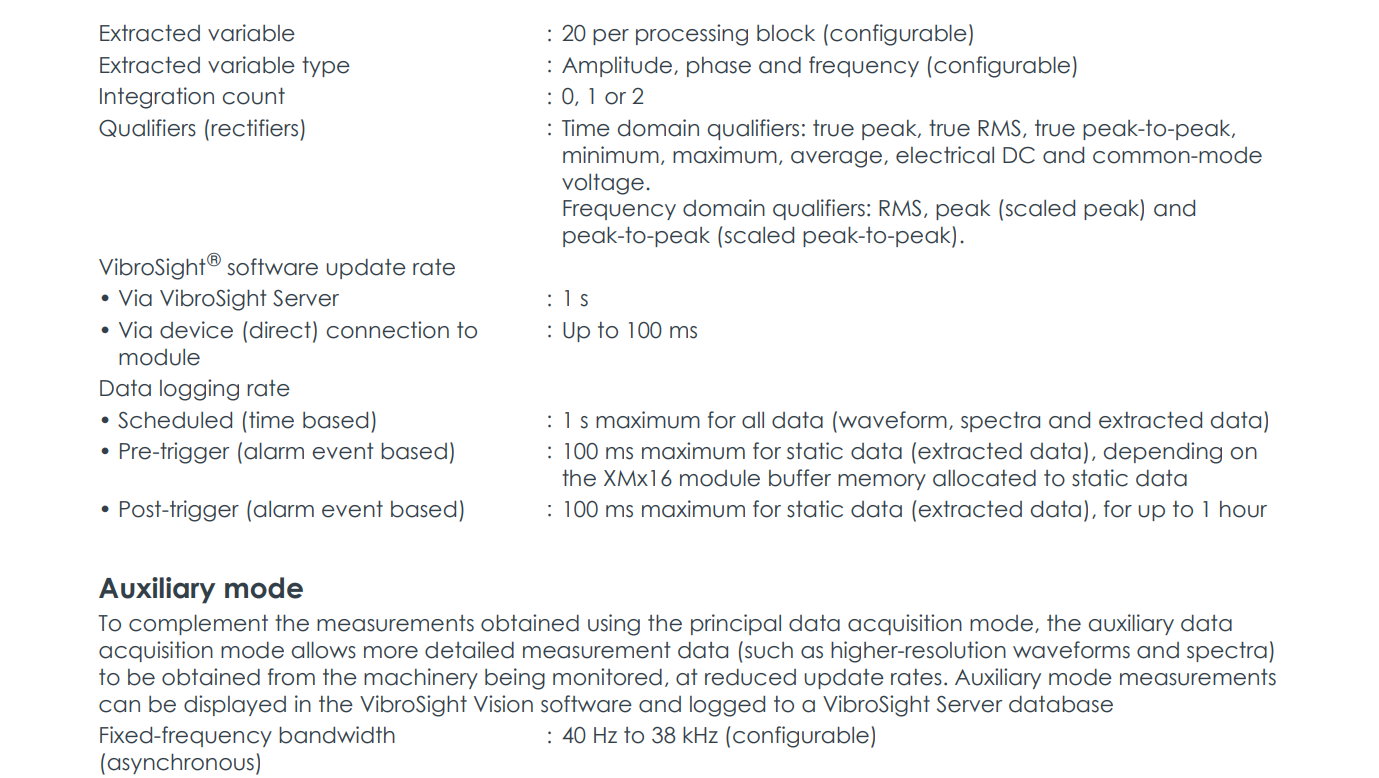

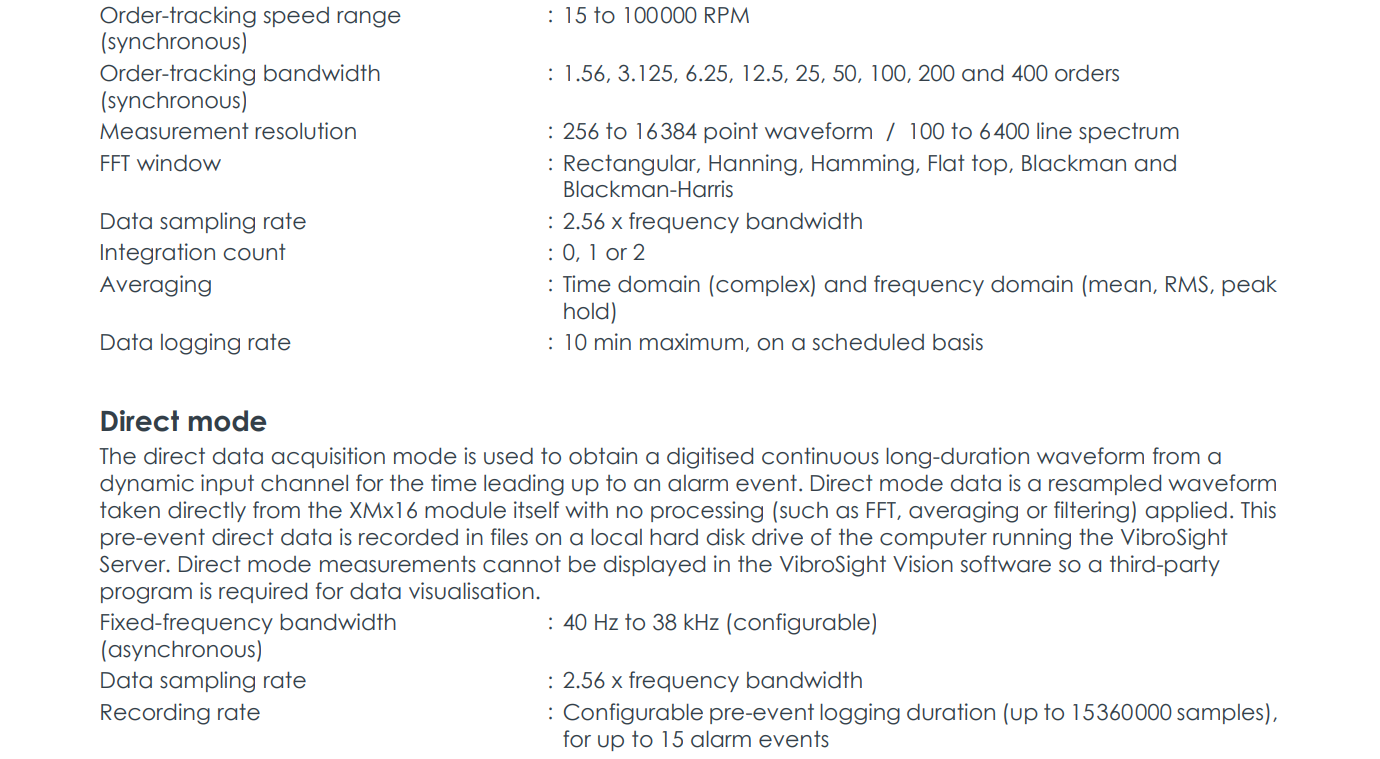

Each input channel includes multi-stage filtering circuits providing anti-aliasing filtering and EMI protection. Filter characteristics are software-configurable to meet different application needs. The dynamic input frequency bandwidth is 0.10 Hz to 38 kHz (AC mode) or DC to 1.0 Hz (DC mode), and users can select appropriate high-pass filter cutoff frequencies (1.0 Hz, 3.0 Hz, or 10.0 Hz) as needed.

The module provides comprehensive overvoltage and overcurrent protection. All inputs can withstand up to ±50 V common-mode voltage and 30 V signal voltage, ensuring reliable operation in industrial environments.

4. Signal Sharing Mechanism

The XIO16T supports signal sharing within VM600 racks, which is one of its most important features. Through the backplane's Raw bus and Tacho bus, the module can share signals with other processing modules (such as MPC4Mk2/MPC4 machinery protection modules).

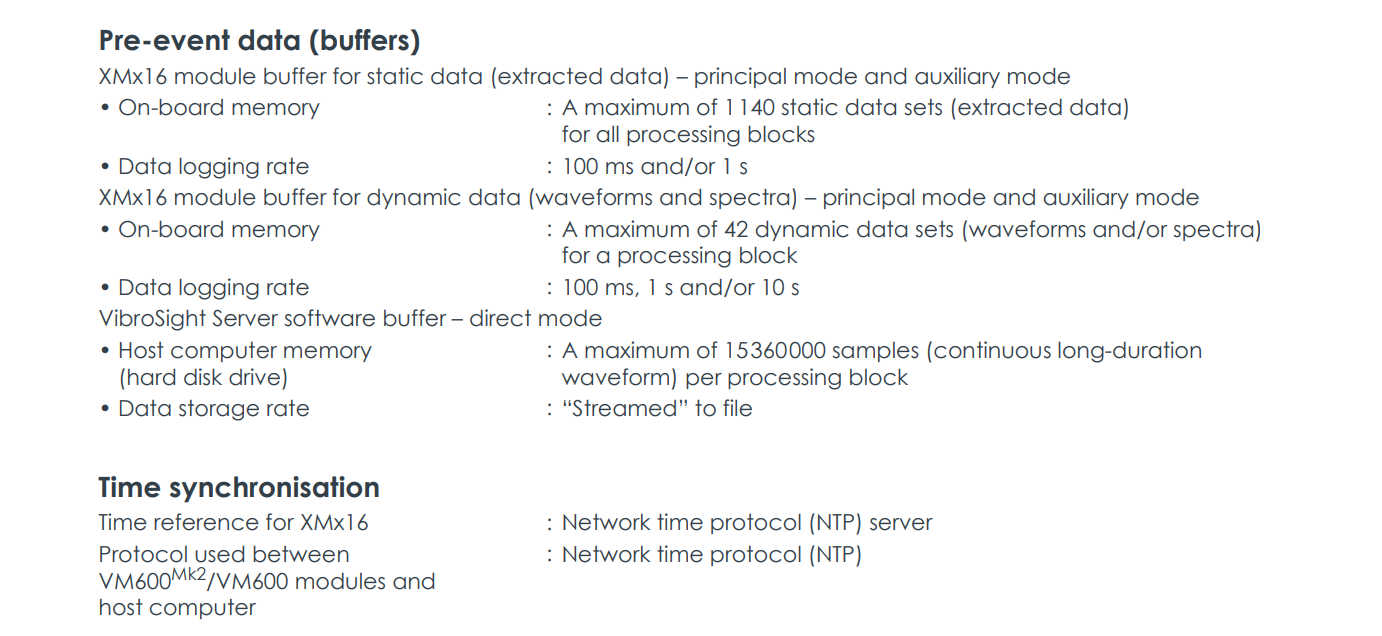

The Raw bus is used to share dynamic input signals, supporting up to 32 signal lines. The Tacho bus is used to share tachometer input signals, supporting up to 6 signal lines. This signal sharing mechanism greatly simplifies system wiring, reduces the need for duplicate signal acquisition, and improves system consistency and reliability.

5. Communication Interface Function

The module provides two Gigabit Ethernet interfaces, one located on the front panel (on the XMx16 module) and one on the rear panel (on the XIO16T module). These interfaces are redundant, allowing users to choose which interface to use based on actual needs.

The Ethernet interfaces use the 1000BASE-T standard, supporting data transfer rates up to 1000 Mbps. The interfaces use TCP/IP protocol to communicate with computers running VibroSight software for configuration, data acquisition, and status monitoring functions.

6. Power Management & Distribution

The XIO16T module receives operating power (+5 VDC and ±12 VDC) from the VM600 rack power supply. The power circuit includes multi-stage filtering and voltage regulation design to ensure stable and clean power supply to all parts of the module.

The module's power consumption is optimized: <14 W from the +5 VDC supply, <8 W from the +12 VDC supply, and <4 W from the -12 VDC supply, with total power consumption <26 W (combined with XMx16 module). This low-power design reduces the system's thermal load and improves reliability.

7. Status Monitoring & Diagnostics

The module provides multiple status indicators (LEDs) to display the module's operational status in real-time. The STATUS LED indicates the XIO16T module's configuration status and communication status, while the ETHERNET connector link and activity LEDs indicate the status of system Ethernet communications.

These status indication functions help users quickly identify and diagnose system issues, improving system maintainability and availability.

8. Hot-Swap Mechanism

The XIO16T module supports hot-swap functionality, thanks to carefully designed power sequencing circuits and signal isolation. When a module is inserted into a running system, the power circuit powers up in the correct sequence to avoid current surges; when a module is removed, the signal lines are disconnected before the power, preventing signal interference.

9. Mechanical & Connection Design

The module features a robust mechanical design with dimensions of 6U H × 20mm W × 125mm D and weight of approximately 0.32 kg. The connector system is specially designed, with all connectors being removable for easy installation and maintenance.

The use of B2CF plug-in connectors and dedicated crimp terminals is recommended to ensure connection reliability and consistency. The module comes with a crimp terminal kit containing 100 H0,34/12 TK terminals and 100 H0,5/16 OR terminals.

10. Environmental Adaptability

The XIO16T module is designed for harsh industrial environments, with an operating temperature range of 0 to 65°C and storage temperature range of -40 to 85°C, suitable for most industrial applications. The module is also available with an optional conformal coating version for additional protection against chemicals, dust, moisture, and extreme temperatures.

Applications

The VM600 XIO16T Input/Output Module is ideally suited for the following application areas:

Large Rotating Machinery Monitoring: Vibration condition monitoring for large rotating machinery such as steam turbines, gas turbines, and hydro turbines

Industrial Process Monitoring: Machinery condition monitoring in industries such as petrochemicals, power generation, and metallurgy

Predictive Maintenance Systems: Serving as signal interface components for plant predictive maintenance systems

Critical Equipment Protection: Used in machinery protection and condition monitoring systems for various critical rotating equipment

Test & Measurement Applications: Suitable for various test and measurement applications requiring high-precision signal acquisition

Key Specifications Summary

Dynamic Input Channels: 16 independent channels

Tachometer Input Channels: 4 independent channels

Input Types: Voltage input (-30 to +30 V), Current input (-25 to +25 mA)

Input Impedance: ≥200 kΩ (voltage input), 100 Ω (current input, measuring resistor)

Frequency Bandwidth: 0.10 Hz to 38 kHz (AC), DC to 1.0 Hz (DC)

Communication Interface: Gigabit Ethernet × 2 (1000BASE-T)

Operating Temperature: 0 to 65°C (32 to 149°F)

Connectors: 12-pin and 24-pin S2L connectors, compatible with B2CF plug-in connectors

Dimensions: 6U H × 20mm W × 125mm D

Weight: approx. 0.32 kg