The TQ412 is a high-performance reverse-mount non-contact eddy current displacement transducer from the VM product line. It is specifically designed for the condition monitoring and protection of rotating machinery in industrial environments and serves as a core component of the TQ402/TQ412, EA402, and IQS900 proximity measurement system. Based on the eddy current sensing principle, this system accurately measures relative vibration, axial displacement, and gap changes in rotating machinery shafts. It is widely used in critical equipment such as steam turbines, gas turbines, hydro turbines, generators, turbo-compressors, and pumps.

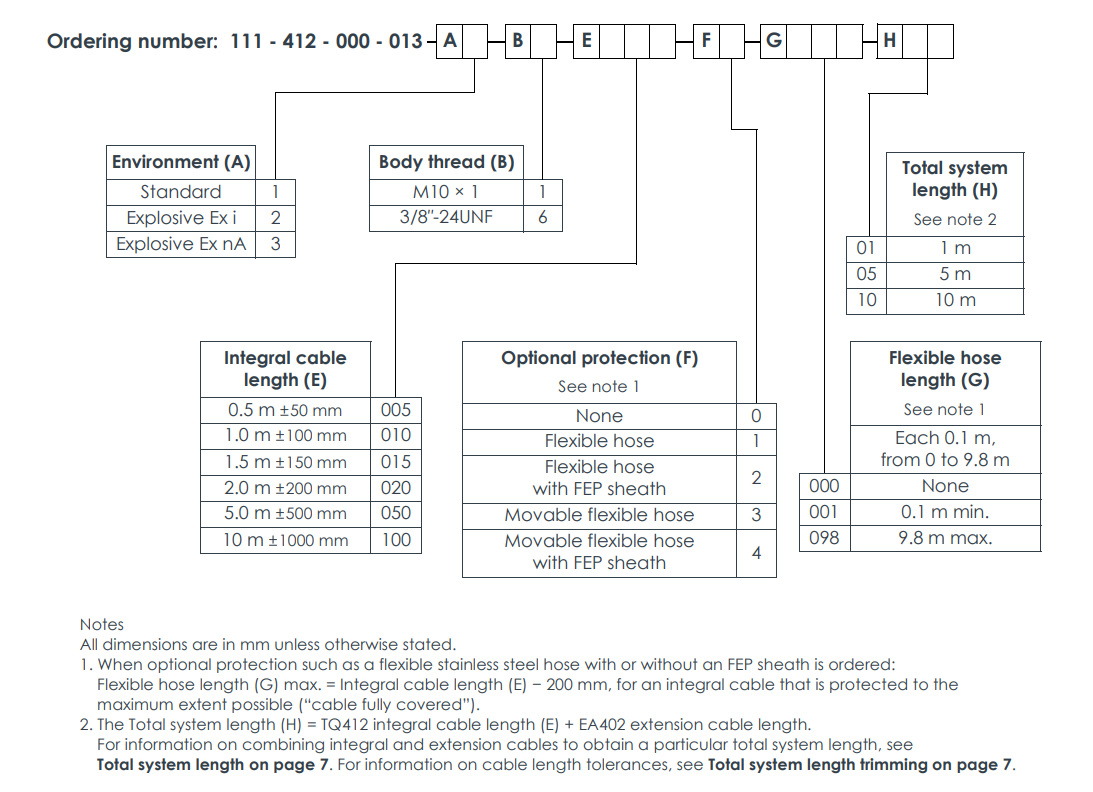

The TQ412 sensor features a reverse-mount design, making it suitable for installation in space-constrained or specially configured scenarios. Together with the EA402 extension cable and the IQS900 signal conditioner, it forms a complete measurement chain. All components are fully interchangeable and require no individual calibration, greatly simplifying system integration and maintenance. The system supports two measurement ranges (2 mm or 4 mm), provides voltage or current output, and complies with API 670 standard recommendations.

Key Features and Functions

1. Non-Contact High-Precision Measurement

Based on the eddy current effect, it measures displacement changes on metal surfaces without physical contact with the target.

Measurement Range: 2 mm or 4 mm (selected via ordering option).

Sensitivity Options:

Frequency Response: DC to 20 kHz (–3 dB), capable of capturing dynamic vibration signals from high-speed rotating machinery.

2. Reverse-Mount Design

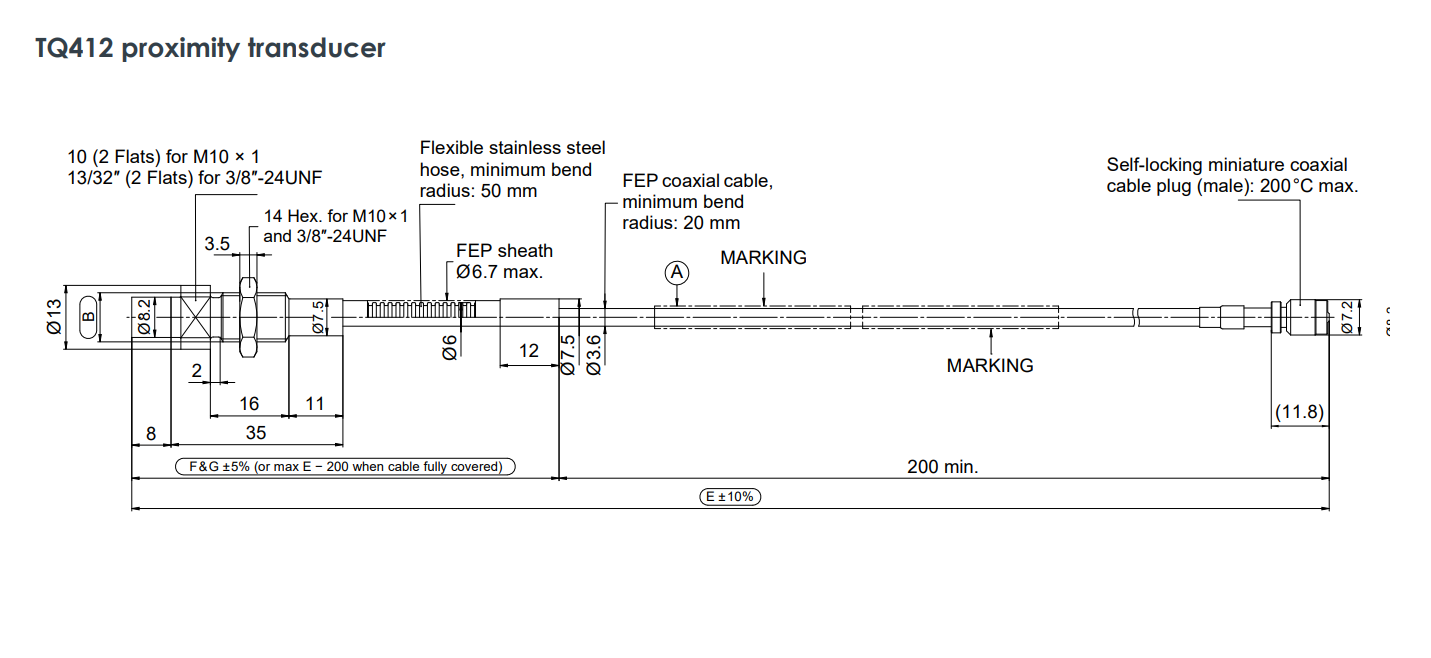

Specifically designed for space-constrained or Special mechanical structure, offering greater installation flexibility.

Provides metric (M10×1) or imperial (3/8"-24UNF) thread options to suit different installation requirements.

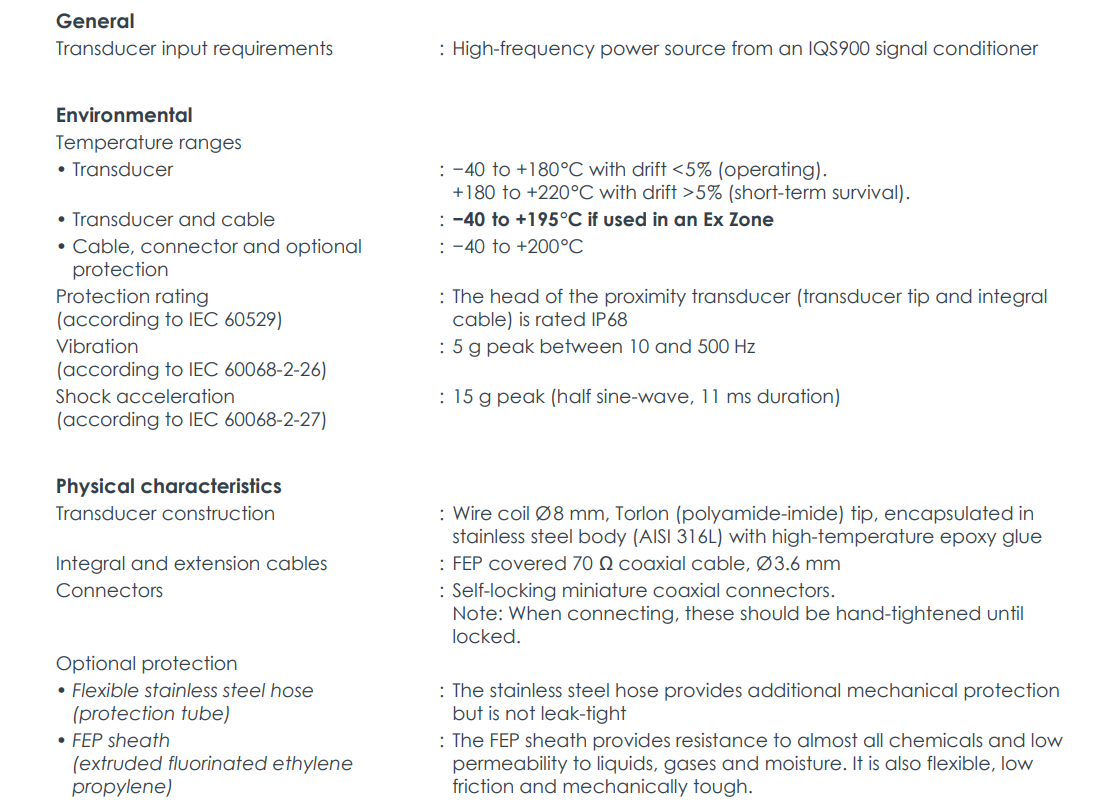

3. High-Temperature and Harsh Environment Adaptability

Transducer Body Operating Temperature Range: –40°C to +180°C (operating), with short-term survival up to +220°C.

Overall Protection Rating: Sensor head rated IP68, suitable for harsh industrial environments such as those with moisture, oil, and dust.

Vibration Resistance: Withstands 5 g peak vibration in the 10–500 Hz range.

Shock Resistance: Withstands 15 g peak shock (half-sine wave, 11 ms duration).

4. Explosion-Proof Certification and Safety

Offers multiple explosion-proof certification options (specified via ordering code):

Ex ia Intrinsic Safety (Option A2): Suitable for Zone 0/1/2 hazardous areas, certified by ATEX, IECEx, cCSAus, and other international standards.

Ex nA Non-Sparking (Option A3): Suitable for Zone 2 hazardous areas.

Both the sensor and cable are explosion-proof certified, ensuring safe use in potentially explosive atmospheres.

5. Modularity and Interchangeability

Fully compatible with TQ402, EA402 cables, and the IQS900 signal conditioner. Components are interchangeable and require no recalibration.

Supports three total system lengths (TSL): 1 m, 5 m, and 10 m, achievable through combinations of different-length sensor integral cables and extension cables.

6. Mechanical and Material Design

The sensor head uses Torlon (polyamide-imide) material to encapsulate the coil, providing excellent high-temperature stability and mechanical strength.

The body is constructed from stainless steel (AISI 316L) for strong corrosion resistance.

Internal high-temperature epoxy resin potting ensures long-term reliability.

Standard self-locking miniature coaxial connectors ensure reliable connections and support high-temperature environments (up to 200°C).

7. Optional Protection Configurations

Detailed Working Principle

1. Eddy Current Effect Fundamentals

The TQ412 sensor operates based on the eddy current sensing principle. Its head contains a coil wound from precision enameled wire, driven by a high-frequency AC excitation signal (typically 1–2 MHz) from the IQS900 signal conditioner. The high-frequency current generates a high-frequency alternating magnetic field around the coil. When the sensor probe approaches a conductive metal target (e.g., a shaft surface), this alternating magnetic field induces closed-loop circulating currents, known as eddy currents, on the conductor surface. The strength of these eddy currents is inversely proportional to the gap distance between the sensor probe and the target surface. According to Lenz's Law, these eddy currents generate an opposing magnetic field that resists the change in the original field. This interaction causes a change in the equivalent impedance (including resistive and inductive components) of the sensor coil. The degree of impedance change has a strict functional relationship with the gap distance, providing the physical basis for precise measurement.

2. Signal Modulation and Demodulation

The IQS900 signal conditioner is the "brain" of the entire system. Its internal circuitry comprises a precision setup of a high-frequency oscillator, modulator, and demodulator. The oscillator's high-frequency signal drives the sensor coil, forming a high-frequency AC bridge. When the coil impedance changes due to gap variation, it unbalances the bridge. The modulator circuit detects this minute imbalance signal (typically at the millivolt level). Subsequently, the demodulator, using techniques like Phase-Sensitive Detection (PSD), demodulates the high-frequency modulated signal containing the gap information into a slowly varying DC voltage signal. This DC signal is proportional to the gap distance. To further enhance accuracy, the conditioner also integrates linearization circuitry and temperature compensation circuitry. The linearization circuit corrects the sensor's inherent non-linear characteristics through methods like polynomial fitting, ensuring a strict linear relationship between the output and distance across the entire measurement range. The temperature compensation circuit continuously monitors the ambient temperature and adjusts circuit parameters to counteract the effects of temperature changes on coil resistance, electronic component characteristics, and cable capacitance. This ensures extremely high measurement stability from -40°C to +180°C, with typical drift less than 5%.

3. Output Signal Types

The IQS900 conditioner converts the processed DC signal into two standard industrial output modes to adapt to different system integration needs:

Voltage Output Mode (3-wire): This mode provides a high-precision voltage signal proportional to the gap, ranging from -1.6 V to -17.6 V. It internally uses a deep negative feedback operational amplifier circuit, achieving very low output impedance (<100 Ω at DC). The advantage of low output impedance is the ability to drive larger capacitive loads and significantly reduce signal attenuation and distortion during long cable transmission. It is well-suited for direct connection to high-impedance input data acquisition systems, PLC analog input modules, or oscilloscopes for diagnosis.

Current Output Mode (2-wire): This mode provides a current signal from -15.5 mA to -20.5 mA. Current output is renowned for its inherent strong immunity to electromagnetic interference (EMI), making it particularly suitable for harsh industrial environments requiring transmission distances of up to several hundred meters. The precise V/I conversion circuit inside the conditioner ensures the current value is unaffected by line resistance changes. The receiving end only requires a ≤350 Ω precision sampling resistor to convert the current signal into a voltage signal for measurement. This simplified design greatly reduces the complexity and cost of the remote receiving equipment.

4. Temperature Compensation and Calibration

The system is calibrated at +23°C ±5°C using standard target material (VCL 140 steel, 1.7225).

Internal temperature compensation circuitry ensures output drift remains below 5% within the range of –40°C to +180°C.

If non-standard target materials (such as stainless steel, aluminum, alloys, etc.) are used, performance curves must be regenerated or sensitivity corrections applied.

5. Diagnostic Functions (Optional)

When paired with an IQS900 signal conditioner featuring diagnostics (Ordering Option C2), the system can achieve:

Chain Diagnostics: Real-time detection of faults in the sensor, cabling, and/or the conditioner itself.

SIL 2 Certification: Complies with IEC 61508 functional safety standards, suitable for safety-related applications.

Fault Indication: Remote alarm indication via output signals falling outside the normal range (e.g., current output > –15.5 mA or < –20.5 mA).

6. System Integration and Signal Processing

The TQ412 sensor, EA402 extension cable, and IQS900 conditioner form a complete measurement chain.

The Total System Length (TSL) requires "electrical trimming" to ensure system performance and interchangeability (e.g., the actual cable length for a 5 m system must be no less than 4.4 m).

The raw signal (RAW/COM pin) and test input (TEST/COM pin) can be used for system debugging and advanced diagnostics.

7. Installation and Mechanical Adaptation

The reverse-mount design makes it suitable for installation in limited spaces or with special geometries.

Offers various body lengths (20–250 mm) and unthreaded length options (0–230 mm).

Optional flexible stainless steel hose or FEP sheath can extend cable life, adapting to high temperature, corrosion, or mechanical wear environments.

Typical Application Scenarios

Rotating Machinery Vibration Monitoring: Relative vibration measurement of shafts in gas turbines, steam turbines, hydro turbines, compressors, and pumps.

Axial Displacement Monitoring: Thrust bearing position, shaft expansion monitoring.

Gap Measurement: Seal clearance, blade tip clearance monitoring.

Safety Protection Systems: Integration with VM series systems to achieve mechanical protection and predictive maintenance.