The EA902 is a high-performance extension cable from VM product line, specifically designed for the TQ9xx series of eddy current proximity sensors (such as TQ902 and TQ912). It is a critical component in forming a complete, calibrated eddy current proximity measurement chain, used to flexibly extend the physical connection distance between the sensor and the signal conditioner (IQS900). The EA902 is not a simple passive cable but a system component that is precision-engineered and calibrated. Its electrical characteristics are strictly matched to the sensor's integral cable and the signal conditioner to ensure the performance metrics (such as sensitivity, linearity, frequency response) of the entire measurement chain are maintained.

The EA902 extension cable, together with the TQ9xx sensor and the IQS900 signal conditioner, forms an interchangeable, pre-calibrated measurement system. This system is widely used in condition monitoring and safety protection systems for large rotating machinery such as steam turbines, gas turbines, hydraulic turbines, generators, turbo-compressors, and pumps, for measuring shaft relative vibration, axial position, keyphasor, and speed.

Designed for harsh industrial environments, the cable offers exceptional signal integrity, environmental tolerance, and mechanical reliability. It is optionally available with various international explosion-proof certifications, enabling its use in hazardous areas. The design of the EA902 ensures that even when combined with the sensor's integral cable to achieve the maximum total system length, it still meets the stringent performance requirements for measurement systems, such as those outlined in API 670 5th Edition.

Working Principle

The working principle of the EA902 extension cable is based on high-frequency signal transmission and impedance matching. Its role in the measurement chain far exceeds that of a simple electrical connection. To understand its operation, it must be viewed within the context of the entire TQ9xx measurement chain:

High-Frequency Signal Transmission Medium:

The IQS900 signal conditioner generates a high-frequency (MHz range) AC excitation signal, which is transmitted via the cable to the coil in the TQ9xx sensor head.

The impedance change of the sensor coil (which reflects the distance to the target) is, in turn, modulated into a high-frequency signal and sent back through the same cable to the IQS900 for demodulation.

As an extension of this transmission path, the EA902's core task is to transmit these high-frequency signals with minimal loss. It employs a coaxial cable structure with a characteristic impedance of 70 Ω, which matches the design of the sensor's built-in cable and the signal conditioner's input/output circuits, aiming to minimize reflection, attenuation, and distortion of the signal during transmission.

System Calibration and Impedance Matching:

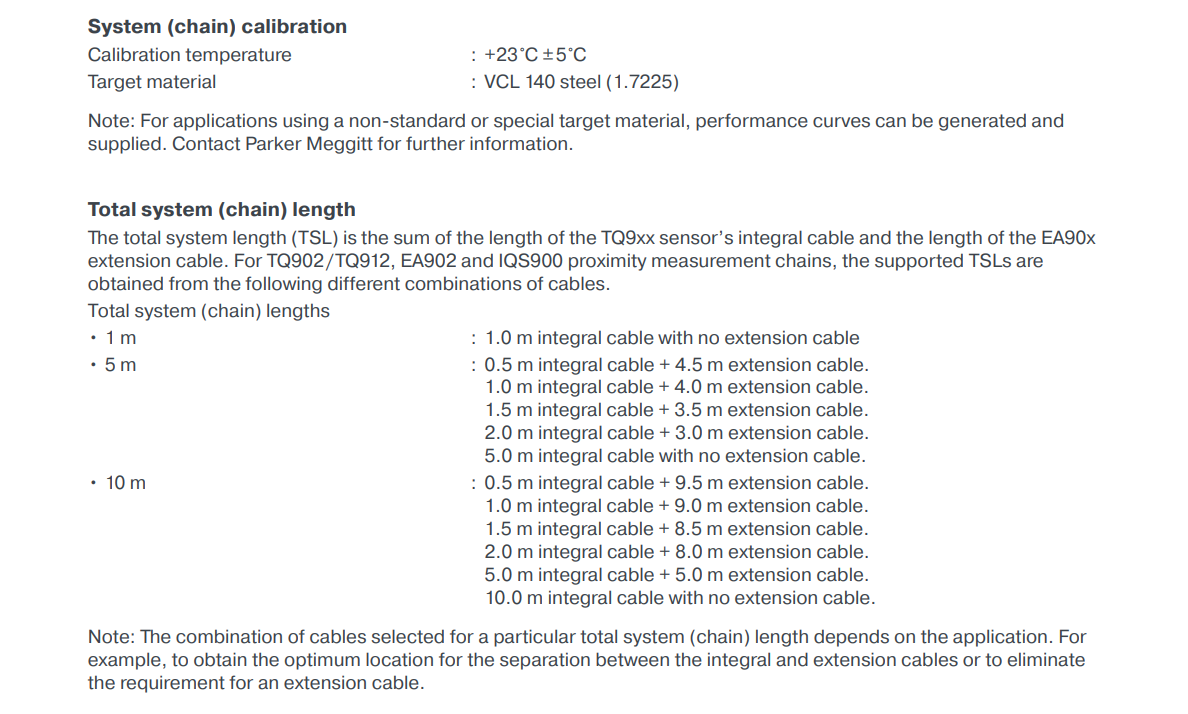

The entire measurement chain (sensor + extension cable + signal conditioner) is calibrated as a whole. The calibration parameters already account for the electrical characteristics of the cable at a specific Total System Length (TSL).

The electrical parameters of the EA902 (especially capacitance and inductance) are strictly controlled. These distributed parameters affect the overall system's resonant frequency and phase response. The design of the IQS900 signal conditioner compensates for these effects within a certain cable length range.

Therefore, the EA902 is not an ordinary cable but a calibrated component with specific and stable electrical characteristics. Replacing it with a different length of EA902 or combining it with sensors of different integral cable lengths essentially changes the system's total electrical length. This requires selecting the corresponding Total System Length (TSL) jumper or configuration on the signal conditioner (e.g., 1m, 5m, 10m) to inform the IQS900, allowing its internal circuits to make corresponding compensations to maintain the calibration status and performance metrics (e.g., 8 mV/μm sensitivity) of the entire link.

Forming a Complete Measurement Loop:

The EA902 connects to the sensor's integral cable via self-locking miniature coaxial connectors, forming a continuous, shielded, consistent characteristic impedance transmission channel from the sensor coil to the signal conditioner's front-end circuit.

This channel is responsible for bidirectional transmission: firstly, delivering high-frequency energy from the signal conditioner to the sensor coil; secondly, returning the signal reflecting the coil's impedance change from the sensor back to the signal conditioner.

The shielding of the EA902 (typically consisting of a braided layer under the FEP sheath) is crucial for suppressing external electromagnetic interference (EMI), ensuring the weak high-frequency measurement signal remains uncontaminated over long-distance transmission.

Importance of Length Trimming:

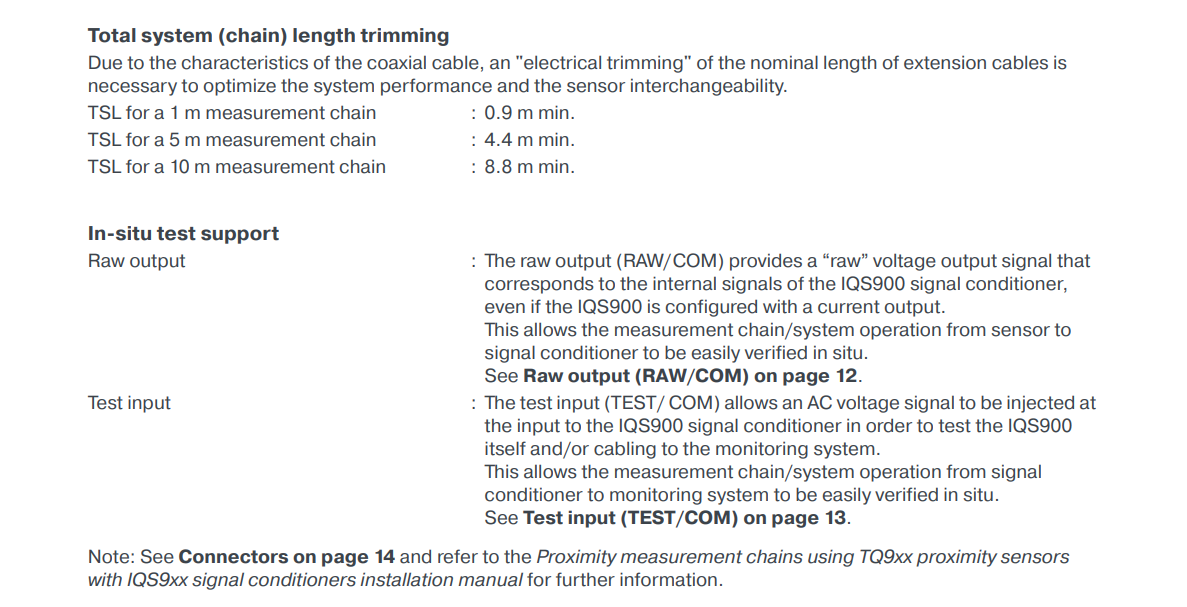

Due to the inherent distributed parameters of coaxial cables, cables of the same nominal length may have slight differences in actual electrical length. To optimize system performance (especially linearity) and ensure complete interchangeability of components, an "electrical trimming" of the nominal length of the extension cable is necessary.

This means that for an EA902 cable nominally rated at 5.0 meters, the actual minimum electrical length requirement (for a 5m measurement chain) is 4.4 meters. This trimming ensures that the total electrical characteristics of any compliant EA902 cable, when combined with a sensor, fall within the range that the IQS900 signal conditioner can accurately compensate for.

In summary, the EA902 extension cable effectively extends the electrical interface of the TQ9xx sensor to the IQS900 signal conditioner by providing a transmission path with stable characteristic impedance, good shielding, and precisely controlled electrical length. As an integral part of the entire measurement chain, its characteristics are considered in the system calibration, ensuring that the entire system can still provide high-precision, highly reliable measurement signals even after extending the connection distance.

III. Core Functions and Features

As a critical link in the high-performance measurement chain, the EA902 extension cable possesses the following outstanding functions and features:

Distance Extension and System Integration:

Core Function: Its primary function is to extend the physical distance between the TQ9xx sensor and the IQS900 signal conditioner. It allows the sensor to be installed at critical monitoring points on machinery while placing the signal conditioner in a control room or junction box that is more convenient for maintenance and offers a better environment.

Pre-calibrated System Component: The EA902 is not a generic cable but a system component calibrated for use with specific sensors and signal conditioners. This ensures the performance of the entire measurement chain (sensitivity, linear range, frequency response) remains compliant with specifications (e.g., API 670 5th Edition) even after extension.

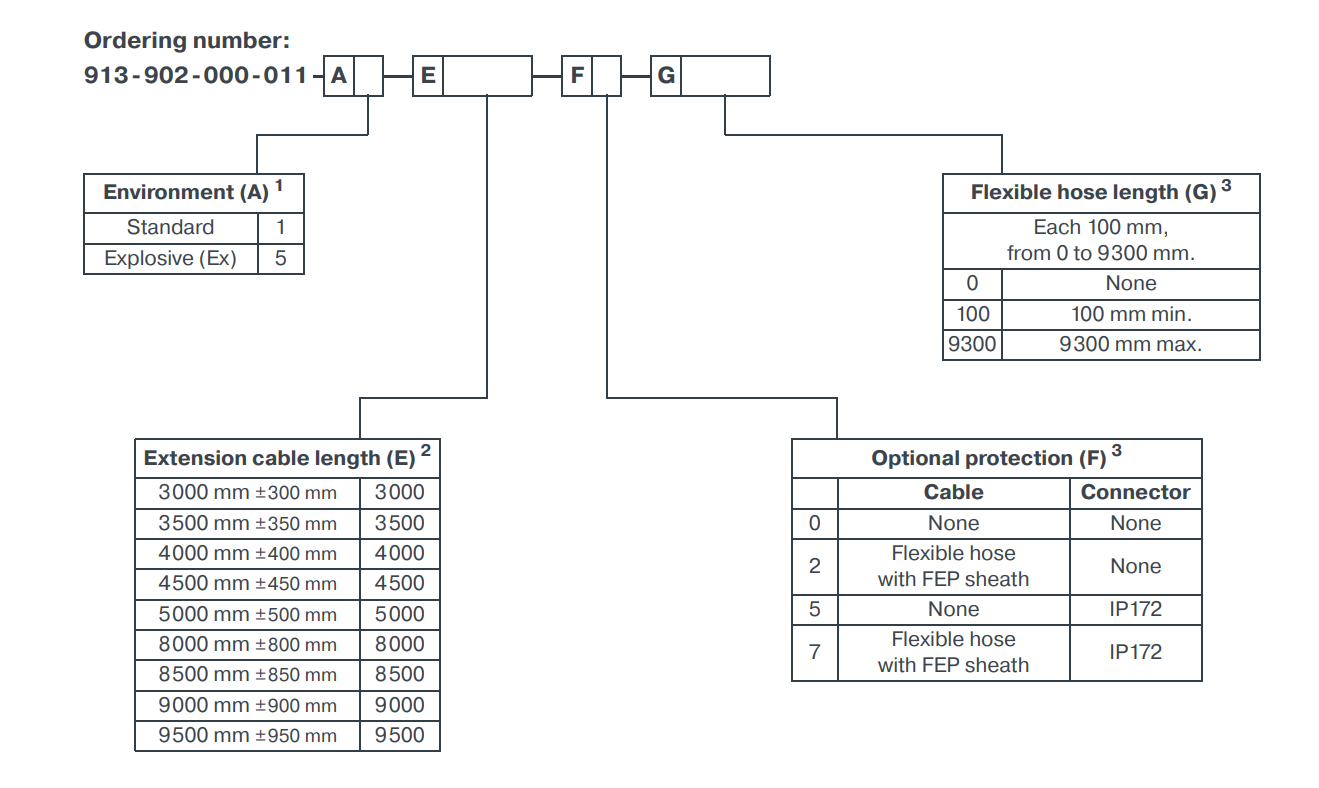

Total System Length (TSL) Flexibility: Available in various standard lengths (e.g., 3.0m, 3.5m, 4.0m, 4.5m, 5.0m, 8.0m, 8.5m, 9.0m, 9.5m). These can be flexibly combined with different lengths of the TQ9xx sensor's integral cable (e.g., 0.5m, 1.0m, 1.5m, 2.0m, 5.0m, 10.0m) to achieve the required final 1-meter, 5-meter, or 10-meter Total System Length, meeting the wiring needs of different application sites.

Excellent Electrical Performance and Signal Integrity:

Coaxial Structure and Impedance Matching: Uses a coaxial structure with a 70 Ω characteristic impedance, matching the interface impedance at the sensor and signal conditioner ends, minimizing signal reflection and ensuring the integrity of high-frequency measurement signals.

Low-Loss Transmission: High-quality core wire and shielding design ensure minimal attenuation of signals over transmissions of several meters, guaranteeing measurement accuracy.

High-Frequency Response: Its design supports the overall measurement chain achieving a wide frequency response of DC to 20 kHz (~3 dB), capable of accurately capturing everything from slow axial displacement to high-speed rotor vibration.

Robust Environmental Adaptability and Reliability:

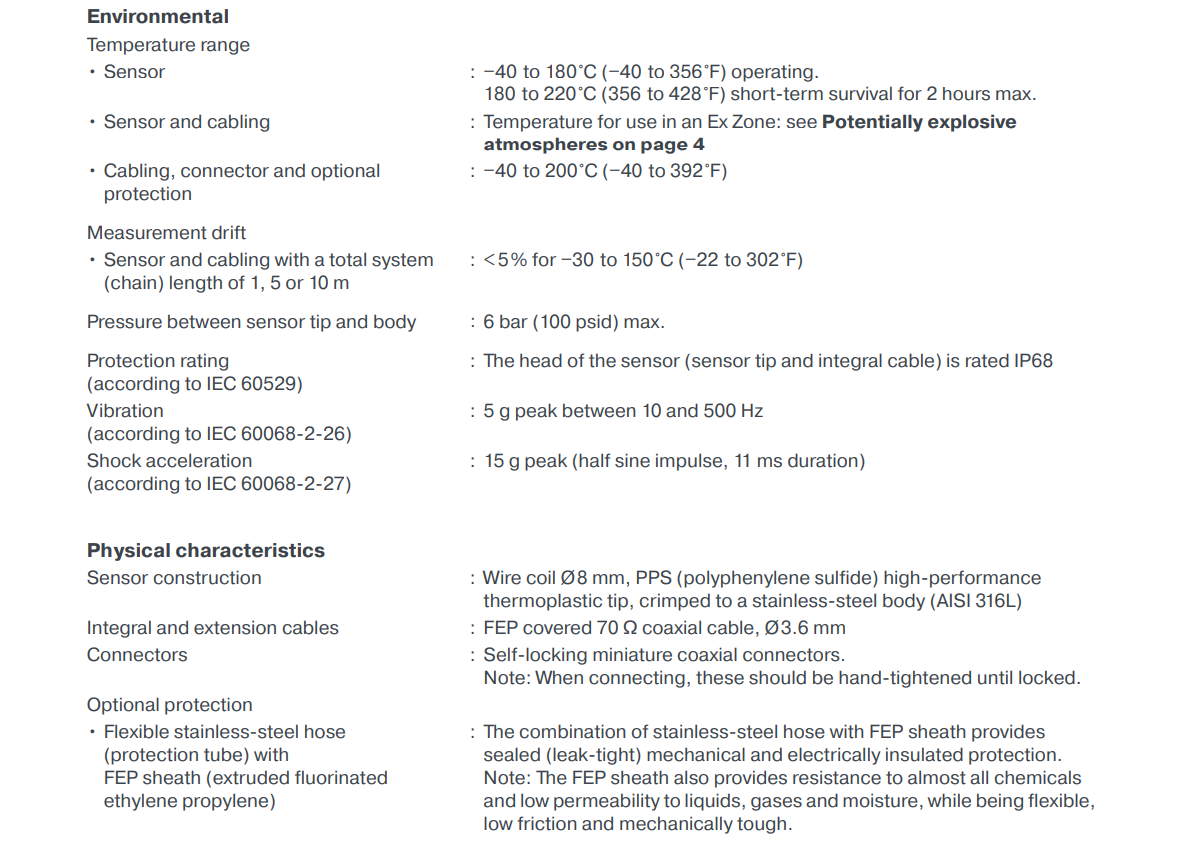

Wide Temperature Range: The cable, connectors, and optional protection kits can operate in ambient temperatures from -40°C to +200°C. Its temperature limits for use in hazardous areas depend on the selected explosion-proof certification grade (refer to the Ex certification table in the technical documentation).

High Protection and Durability: The cable body is covered with an FEP (Fluorinated Ethylene Propylene) sheath. FEP material offers excellent chemical resistance, resisting almost all chemicals, while also having low permeability to liquids, gases, and moisture. Additionally, it is flexible, has low friction, and is mechanically tough.

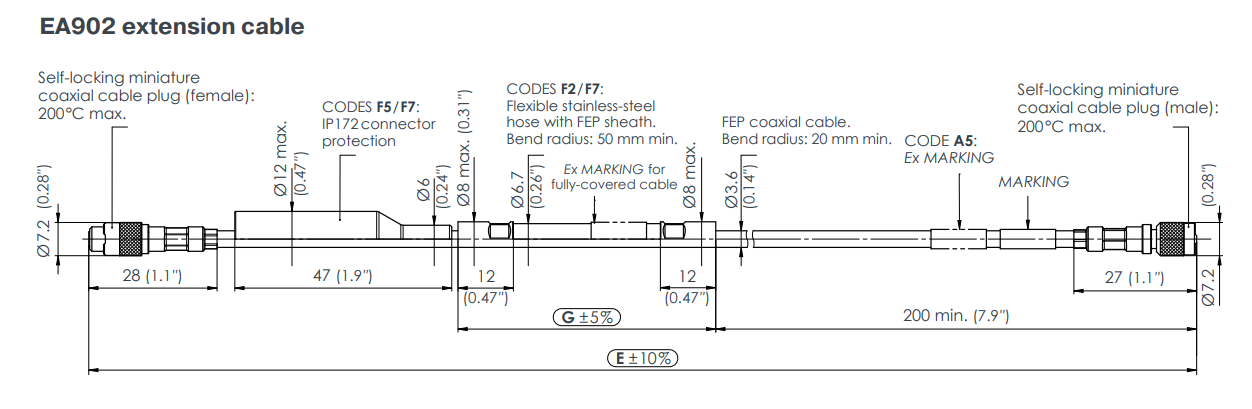

Mechanical Protection Options: Optional flexible stainless steel hose with an FEP sheath (ordering option codes F2, F7). This combination provides comprehensive protection that is sealed (leak-tight), resistant to mechanical shock and abrasion, and electrically insulated, especially suitable for occasions where the cable might contact moving parts, high-temperature surfaces, or harsh chemical environments.

Comprehensive Hazardous Area Certification (Optional):

Explosion-Proof Certification: Optional A5 (Ex) version is available, obtaining various international explosion-proof certifications suitable for use in explosive atmospheres (e.g., ATEX, IECEx, cCSAus/UL, UKEX, KGS, EAC, etc.). In explosion-proof applications, the EA902 is certified as suitable for the explosion-proof type of its matching IQS9xx signal conditioner (e.g., Ex ec or Ex ia).

System Compliance: When used in hazardous areas, every component of the measurement chain (TQ9xx, EA902, IQS900) must have corresponding and compatible explosion-proof certification (i.e., must all be ordered with the A5 option). The EA902 is a key part of achieving overall system compliance.

Convenient Connection and Installation:

Self-Locking Connectors: Both ends of the cable are equipped with self-locking miniature coaxial connectors (one male, one female). The connectors feature a threaded locking design; simply hand-tighten until locked, ensuring a secure and reliable connection capable of withstanding temperatures up to 200°C.

Connection Point Protection: Optional IP172 interconnection protector (ordering option codes F5, F7) provides mechanical and environmental protection for the connection point between the sensor's integral cable and the EA902 extension cable, preventing moisture, dust, and physical damage.

Installation Flexibility: The flexible cable body and optional stainless steel hose protection make routing more flexible and easier to run and secure within complex machinery layouts.

Component Interchangeability and System Maintenance:

Fully Interchangeable: All compliant EA902 extension cables are interchangeable. This means that if a cable needs replacement, recalibration of the entire system is not required; simply replace it with an EA902 of the same length and option code, greatly simplifying spare parts management and field maintenance.

Facilitates System Debugging and Troubleshooting: When used with an IQS900 signal conditioner that supports raw signal output (RAW/COM) and test input (TEST/COM), it facilitates on-site (in-situ) testing and troubleshooting of the entire cable path, including the EA902.