The TQ402 Proximity Transducer is a core component of the TQ402/TQ412, EA402, and IQS900 proximity measurement system. This system forms a complete, non-contact displacement measurement chain based on the eddy current principle, specifically designed for condition monitoring and protection of industrial rotating machinery.

Known for its high precision, reliability, and exceptional environmental resilience, the TQ402 transducer is widely used in critical equipment such as steam turbines, gas turbines, hydraulic turbines, generators, turbo-compressors, and pumps for measuring relative shaft vibration and axial position. The system design complies with API 670 standards and is available in versions certified for use in potentially explosive atmospheres, making it an ideal choice for high-end industrial applications.

II. Key Features

High Precision and Non-Contact Measurement

The TQ402 accurately measures minute changes in the gap between the probe tip and the target metal surface, converting them into corresponding electrical signals. This non-contact method avoids wear on rotating components, making it perfectly suited for harsh operating conditions involving high speeds and temperatures.

Full System Component Interchangeability

The entire measurement system (including TQ402/TQ412 probes, EA402 extension cables, and the IQS900 signal conditioner) is precision-calibrated, with all components being fully interchangeable. Users can replace any component without the need for complex on-site matching or recalibration, maintaining specified system performance. This greatly simplifies maintenance and reduces inventory costs.

Wide Measurement Range and Output Options

The system offers two standard linear measurement ranges: 2 mm (0.15 to 2.15 mm) and 4 mm (0.3 to 4.3 mm). The IQS900 signal conditioner provides both voltage (-1.6 V to -17.6 V) and current (-15.5 mA to -20.5 mA) output options, facilitating integration with various backend monitoring systems like VM600 or VibroSmart®.

Exceptional Environmental Robustness

Temperature Range: The transducer body operates reliably from -40°C to +180°C with less than 5% drift, and can survive short-term exposure up to +220°C.

Protection Rating: The probe tip and integral cable part are rated IP68, protecting against dust ingress and prolonged immersion in water.

Mechanical Strength: It can withstand 5 g peak vibration (10-500 Hz) and 15 g peak shock (11 ms duration), ensuring stable operation in highly vibrating environments.

Rugged Physical Construction

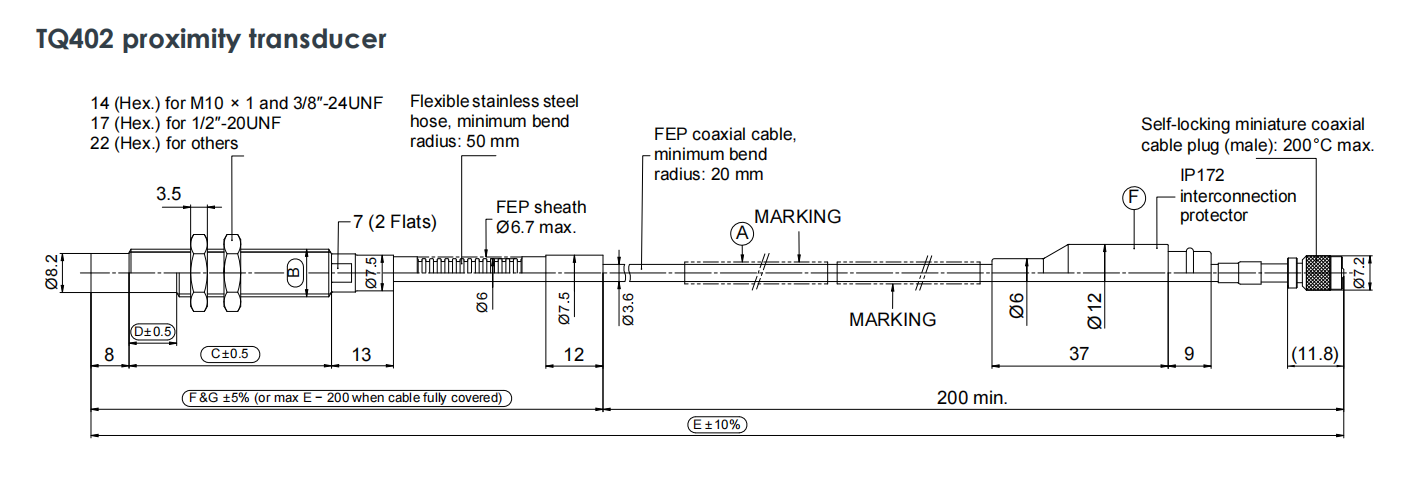

Probe Tip: Features a coil encapsulated within a tip molded from Torlon® (polyamide-imide), offering excellent high-temperature resistance, corrosion resistance, and mechanical strength.

Transducer Body: Constructed from AISI 316L stainless steel and potted with high-temperature epoxy resin, ensuring overall robustness and durability.

Cable and Connectors: Utilizes a 75 Ω coaxial cable with FEP insulation, 3.6 mm in diameter. Connectors are self-locking miniature coaxial types, which lock securely with hand-tightening and feature an anti-loosening mechanism.

Comprehensive Safety Certifications and Compliance

The TQ402 is available in versions certified for use in hazardous areas, including:

Ex ia Intrinsic Safety (for Zone 0, 1, 2).

Ex nA Non-Sparking (for Zone 2).

Additionally, the system complies with multiple international standards and directives such as CE, EAC, and RoHS.

III. Working Principle

The TQ402 proximity transducer and its system operate based on the core physical principle of the eddy current effect. The following details the complete process from signal generation to final output.

1. Generation of the Eddy Current Effect

The heart of the TQ402 sensor is a precision-wound coil, molded inside the rugged Torlon® probe tip. When the system is powered, the accompanying IQS900 signal conditioner supplies this coil with a high-frequency alternating current (typically 1-2 MHz). According to the laws of electromagnetism, this alternating current generates a high-frequency alternating electromagnetic field around the probe tip.

When the probe approaches a conductive metal target (e.g., a machine's steel shaft), this alternating electromagnetic field penetrates the target surface. Faraday's Law of Induction dictates that a changing magnetic field induces closed-loop circulating currents, known as eddy currents, within the conductor. The density and intensity of these eddy currents are closely related to the distance between the probe and the target.

2. Impedance Change and Signal Detection

The induced eddy currents themselves generate an opposing electromagnetic field (Lenz's Law), which interacts with the original field produced by the probe coil. This interaction causes a change in the effective AC impedance of the probe coil. Specifically, as the distance decreases, the coupling effect strengthens, the eddy current effect becomes more significant, and the coil's impedance increases. Conversely, as the distance increases, the impedance decreases.

Thus, the gap distance between the probe and the target is directly converted into a change in the electrical impedance of the TQ402 sensor coil. This impedance change contains information about both the static (average distance) and dynamic (vibration) aspects of the gap.

3. Signal Conditioning and Demodulation

The role of the IQS900 signal conditioner is to detect and process this subtle impedance change. It contains a precise modulator/demodulator circuit. The conditioner continuously monitors changes in the drive signal supplied to the coil resulting from the impedance variation.

Through demodulation of the returned high-frequency signal, the IQS900 accurately extracts the voltage or current component proportional to the gap distance. This process filters out the high-frequency carrier wave, leaving only the low-frequency (DC to 20 kHz) signal related to the distance.

4. Linearization and Output

The demodulated signal is amplified and linearized, converted into a standard, easily measurable electrical signal output:

Voltage Output Mode: Outputs a DC voltage proportional to the gap, with typical sensitivities of 8 mV/μm (200 mV/mil) for the 2mm range, or 4 mV/μm (100 mV/mil) for the 4mm range. The linear output typically ranges from -1.6 V (minimum gap) to -17.6 V (maximum gap).

Current Output Mode: Outputs a current proportional to the gap, with typical sensitivities of 2.5 μA/μm (62.5 μA/mil) or 1.25 μA/μm (31.2 μA/mil). The linear output typically ranges from -15.5 mA (minimum gap) to -20.5 mA (maximum gap).

The system exhibits excellent linearity within its specified range (e.g., 2mm or 4mm), ensuring a highly accurate proportional relationship between the output voltage/current and the mechanical gap.

5. Separation of Static and Dynamic Signals

The final output signal contains both DC (Direct Current) and AC (Alternating Current) components:

DC Component: Represents the average position or static gap between the probe and the target, used for monitoring slow-changing parameters like axial displacement or bearing wear.

AC Component: Superimposed on the DC component, it represents the dynamic vibration of the target relative to the probe. Its amplitude reflects vibration intensity, and its frequency indicates the source of the vibration. This allows the system to perform both position and vibration monitoring simultaneously.

6. Temperature Compensation and System Calibration

To ensure measurement accuracy across the entire operating temperature range (-40°C to +180°C), the system design incorporates temperature compensation mechanisms to minimize the impact of temperature drift on the output. The transducer is factory-calibrated using VCL 140 steel (1.7225) as the target material, which is equivalent to common shaft materials like AISI 4140. For applications with special materials, consultation with the manufacturer is recommended to obtain specific performance curves.

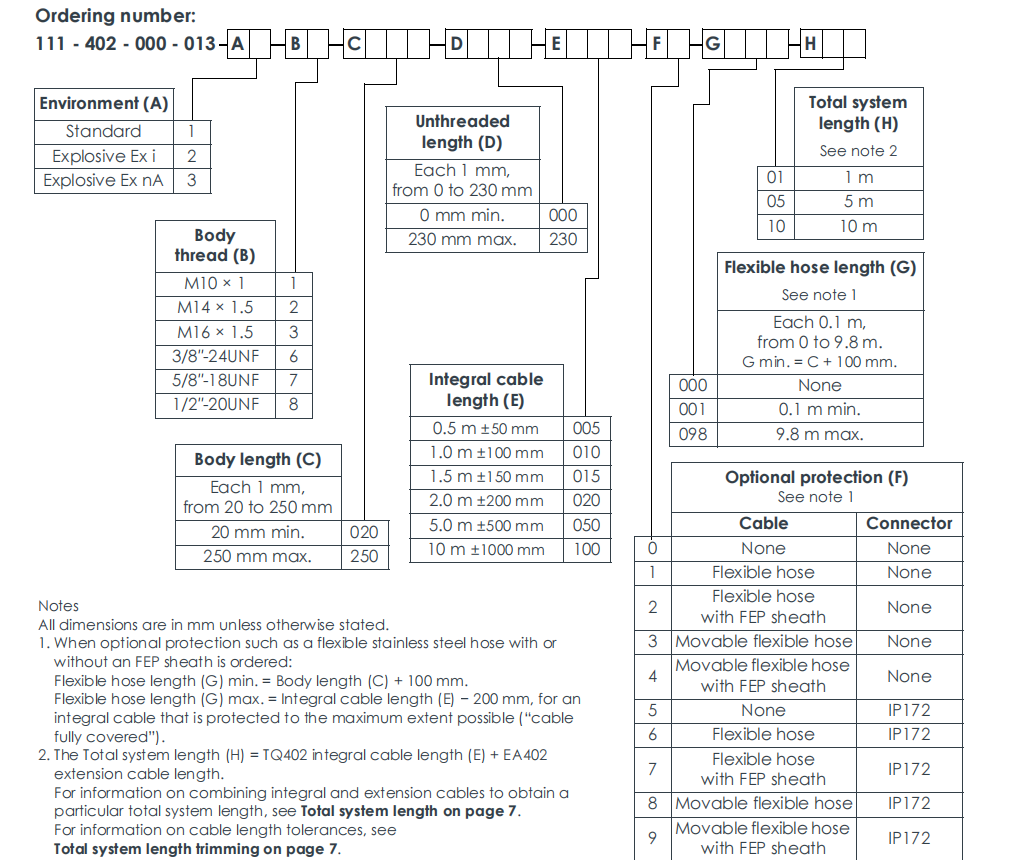

IV. System Integration and Selection Points

Total System Length: The total system length is the sum of the TQ402 transducer's integral cable length and the EA402 extension cable length. Standard system lengths are 1 meter, 5 meters, and 10 meters, achievable through flexible combinations of different probe and extension cable lengths.

Electrical Trimming: To ensure system performance and interchangeability, the nominal length of extension cables requires "electrical trimming." The actual usable minimum total length is slightly less than the nominal value (e.g., 4.4 m minimum for a 5 m system).

Optional Protection: Flexible stainless steel hoses with FEP sheaths can be selected to provide additional mechanical protection and chemical resistance for the cables.

Installation: The transducer body offers both metric and imperial thread options and can be paired with various mounting brackets to suit different installation spaces and requirements.

V. System Diagnostics and Safety Integrity (SIL)

The TQ402 system, in conjunction with the IQS900 signal conditioner, offers advanced features catering to the needs of modern industrial safety and reliability.

Built-in Diagnostic Functionality: The IQS900 signal conditioner offers an optional Built-In Self-Test (BIST) diagnostic circuit. When diagnostics are enabled, the system continuously monitors the health of the entire measurement chain (including the sensor, cable, and conditioner itself). Upon detection of opens, shorts, or other faults, it alters the output signal to clearly indicate the problem:

In voltage/current output mode, the output value will fall outside the normal -1.6 V to -17.6 V or -15.5 mA to -20.5 mA range, providing a clear fault alarm to the backend monitoring system and enabling predictive maintenance.

Functional Safety Certification: The IQS900 signal conditioner with diagnostics is designed to meet SIL 2 (according to IEC 61508) and PL c, Cat. 1 (according to ISO 13849) Safety Integrity Levels. This means the system's design is adequate to meet the stringent requirements of many safety-related applications (e.g., machinery protection systems), helping users more easily build production systems that comply with safety standards.

VI. Mechanical Configuration and Installation Options

Flexible Mechanical Configuration:

Thread Specifications: The TQ402 transducer body offers various thread options, including metric M10x1, M14x1.5, M16x1.5, and imperial 3/8"-24UNF, 1/2"-20UNF, 5/8"-18UNF, catering to global equipment and mounting hole standards.

Dimensional Customization: Users can specify the Case Length (from 20 mm to 250 mm) and Unthreaded Length (from 0 mm to 230 mm) based on installation depth requirements, offering high installation flexibility.

Reverse-Mount Model: For applications where the standard TQ402 cannot fit, the series also offers the TQ412 model. The TQ412 is specifically designed for reverse-mount applications, where the probe tip orientation aligns with the cable exit direction, suitable for measurements taken from inside the equipment housing outward.

Connection and Protection Accessories:

Connector Protection: The IP172 interconnection protector is available to safeguard the connection point between the probe cable and the extension cable, preventing contamination by oil, moisture, and mechanical damage.

Cable Protection: Beyond the fixed FEP sheath, flexible stainless steel hoses (protection tubes) are available as an option. These can move relative to the cable for easier installation, providing robust mechanical protection in complex and harsh routing paths.

Mounting Brackets: A variety of probe mounting adapters (e.g., PA15x series) are available, along with the MA130 DIN-rail mounting adaptor for the IQS900 signal conditioner. This supports standard TH 35 rails, facilitating high-density, modular installation within control cabinets.