The EA402 is a high-performance extension cable from the VM product line, specifically designed for measurement systems composed of TQ402/TQ412 eddy current proximity transducers and the IQS900 signal conditioner. As a critical component of the TQ402/TQ412, EA402, and IQS900 proximity measurement system, the primary function of the EA402 extension cable is to extend the installation distance of the sensor while ensuring the integrity and accuracy of signal transmission. Its design meets industrial-grade environmental requirements, making it suitable for high-temperature, humid, oily, dusty, and potentially explosive atmospheres. It is widely used in condition monitoring and protection systems for rotating machinery in sectors such as power generation, petrochemical, maritime, and manufacturing.

The EA402 extension cable is fully compatible with TQ402/TQ412 transducers and the IQS900 signal conditioner. All components are fully interchangeable and require no individual calibration. The system supports three Total System Lengths (TSL): 1 m, 5 m, and 10 m. Users can select different combinations of sensor integral cables and extension cables based on actual application needs to achieve flexible system configuration.

Key Features and Functions

1. Signal Transmission and Integrity Protection

Utilizes a 70 Ω coaxial cable structure to ensure low-loss transmission of high-frequency signals, reducing signal attenuation and distortion.

The outer layer is sheathed with FEP (Fluorinated Ethylene Propylene) material, which offers excellent chemical stability, low permeability, and mechanical toughness, making it suitable for harsh industrial environments.

Minimum bending radius of 20 mm facilitates easy on-site installation and routing.

2. High-Temperature and Environmental Adaptability

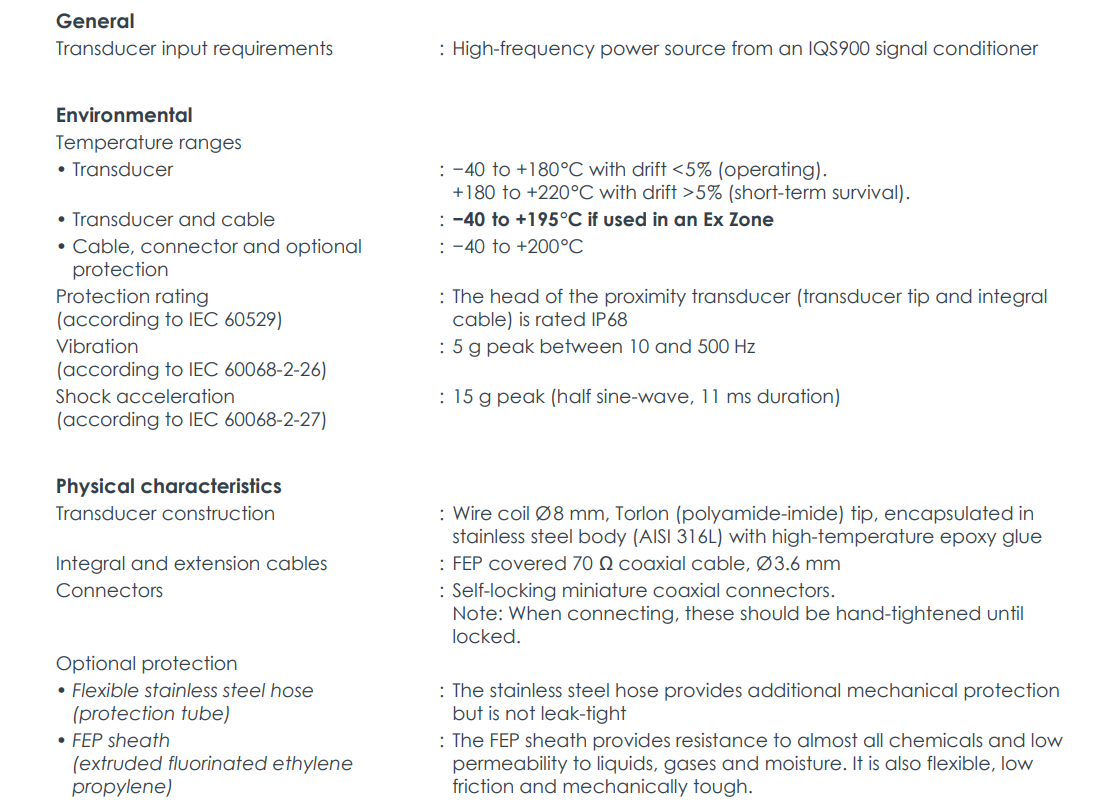

Operating temperature range: –40°C to +195°C (for use in explosive atmospheres), with short-term survival up to +220°C.

Protection rating: The cable connection parts feature high sealing, and the overall design adapts to harsh conditions such as moisture, oil, and dust.

Vibration resistance: Withstands 5 g peak vibration in the 10–500 Hz range.

Shock resistance: Withstands 15 g peak shock (half-sine wave, 11 ms duration).

3. Explosion-Proof Certification and Safety

Offers multiple explosion-proof certification options (specified via ordering code):

Ex ia Intrinsic Safety (Option A2): Suitable for Zone 0/1/2 hazardous areas, certified by ATEX, IECEx, cCSAus, and other international standards.

Ex nA Non-Sparking (Option A3): Suitable for Zone 2 hazardous areas.

Both the cable and connectors are explosion-proof certified, ensuring safe use in potentially explosive atmospheres.

4. Modularity and Interchangeability

Fully compatible with TQ402/TQ412 transducers and the IQS900 signal conditioner. Components are interchangeable and require no recalibration.

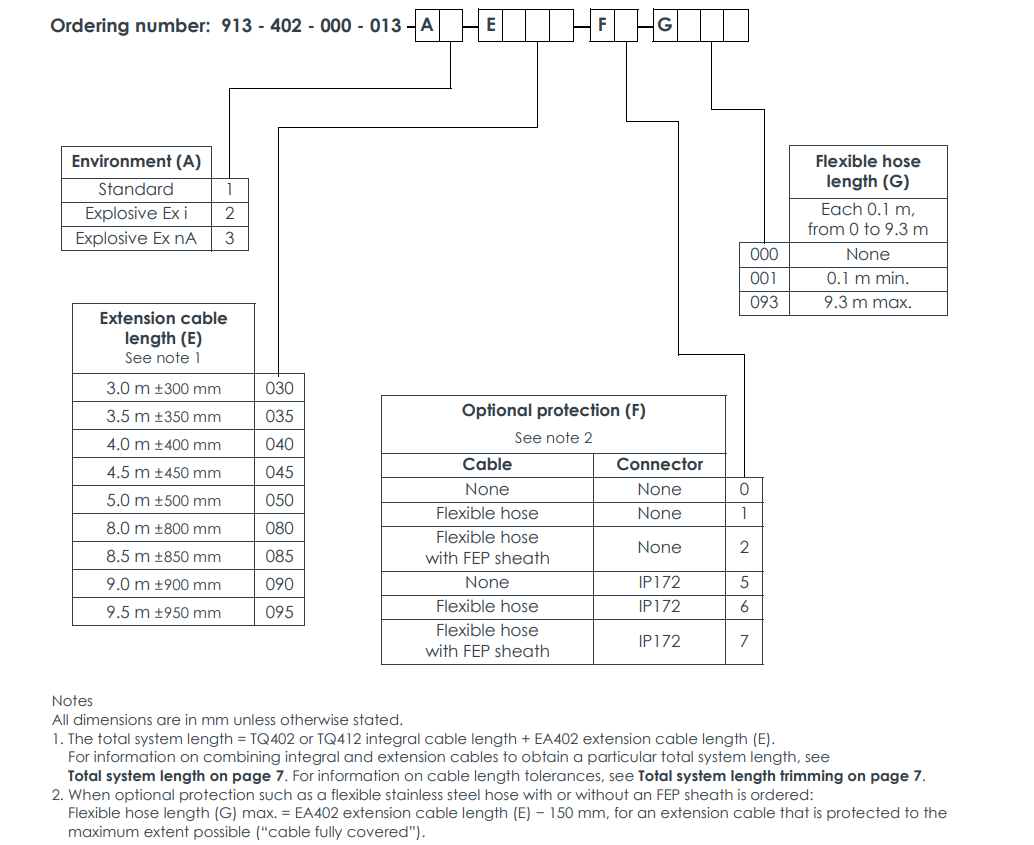

Supports multiple cable length options (3.0 m to 9.5 m). Users can flexibly combine sensor integral cables and extension cables to achieve Total System Lengths (TSL) of 1 m, 5 m, or 10 m.

5. Mechanical and Material Design

Cable construction: The coaxial core uses high-temperature FEP insulation, with an outer layer covered by a stainless steel braided shield, providing excellent electromagnetic shielding.

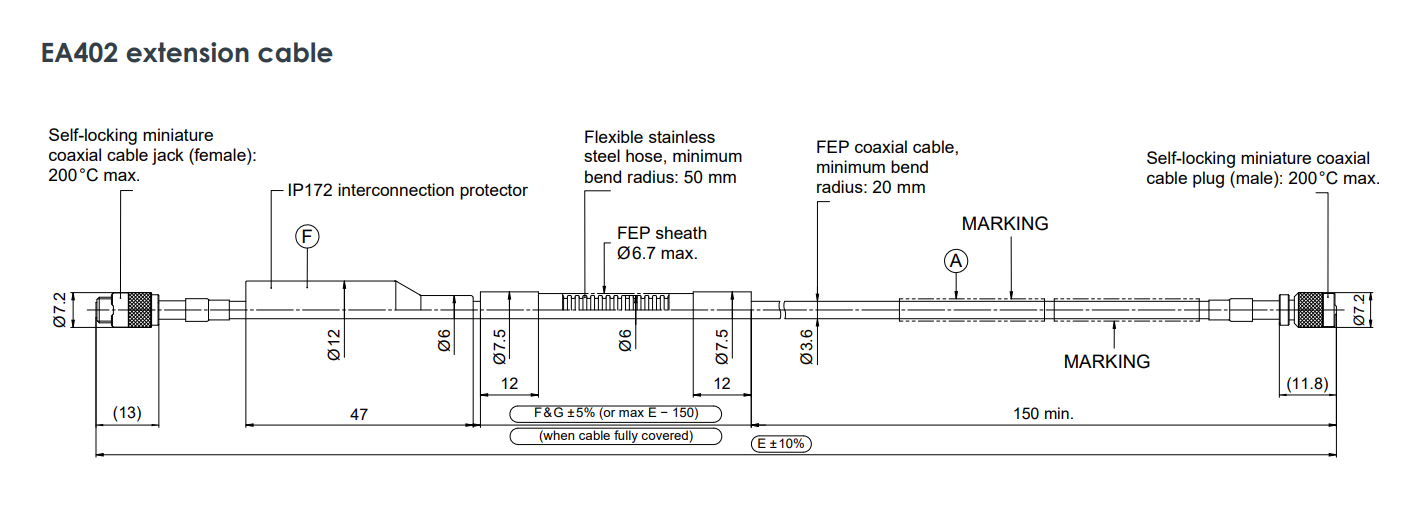

Connectors: Standard self-locking miniature coaxial connectors (female) support high-temperature environments (up to 200°C), ensuring reliable connections and easy on-site installation.

Optional protection configurations:

Flexible stainless steel hose (protection tube): Provides additional mechanical protection but is not leak-tight.

FEP sheath: Offers chemical corrosion resistance and low permeability, suitable for severe operating conditions.

6. Electrical Performance Optimization

Cable impedance is strictly matched to 70 Ω, ensuring consistent signal transmission.

Low capacitance design (typical value <100 pF/m) reduces signal delay and distortion.

Supports high-frequency signal transmission (up to 20 kHz), meeting the requirements for dynamic vibration measurement.

Detailed Working Principle

1. Signal Transmission Mechanism

The core function of the EA402 extension cable is to extend the physical distance between the sensor and the signal conditioner while maintaining the integrity and accuracy of signal transmission. Its working principle is based on the high-frequency signal transmission characteristics of coaxial cables:

Coaxial Structure: The cable consists of an inner conductor (core), insulation layer (FEP material), shielding layer (stainless steel braid), and outer sheath. The inner conductor transmits high-frequency signals, while the shielding layer effectively isolates external electromagnetic interference, ensuring signal purity.

Impedance Matching: The cable impedance is strictly controlled at 70 Ω, matching the impedance characteristics of the TQ402/TQ412 transducers and the IQS900 signal conditioner, thereby reducing signal reflection and attenuation.

Low-Loss Transmission: The FEP insulation layer has a low dielectric constant and low loss factor, making it suitable for high-frequency signal transmission and ensuring high signal-to-noise ratio over long distances.

2. Electrical Trimming and System Optimization

Due to the distributed parameters (capacitance, inductance) of coaxial cables varying with length, the EA402 extension cable requires electrical trimming to ensure system performance and interchangeability:

Electrical Trimming Principle: By precisely controlling the electrical length (rather than the physical length) of the cable, phase and amplitude variations caused by different cable combinations are compensated. For example, the actual cable length for a 5 m system is no less than 4.4 m, and for a 10 m system, no less than 8.8 m.

System Calibration: After the cable, sensor, and conditioner form a system, they undergo end-to-end calibration at the factory to ensure a linear relationship between the output signal and the gap distance. Users require no on-site calibration, enabling true plug-and-play operation.

3. Temperature Compensation and Environmental Adaptability

The EA402 extension cable is designed for performance stability across a wide temperature range:

Temperature Compensation Mechanism: The temperature coefficient of the cable materials is optimized to minimize the impact of temperature changes on impedance and signal attenuation.

High-Temperature Endurance: FEP material can operate stably from –40°C to +195°C, with short-term survival up to +220°C.

Explosion-Proof Design: Certified explosion-proof versions of the cable employ special sealing and shielding designs to ensure safe operation in hazardous environments.

4. Installation and Mechanical Protection

The EA402 extension cable supports various installation methods and protection configurations:

Connector Design: Self-locking miniature coaxial connectors (female) pair with the connectors (male) on the sensor and conditioner. Hand-tightening locks them in place, ensuring a reliable connection.

Optional Protection Kits:

Flexible stainless steel hose: Provides mechanical protection, suitable for high-temperature, high-pressure, or mechanically abrasive environments.

FEP sheath: Provides chemical protection, suitable for corrosive media environments.

Length Flexibility: Users can select extension cables of different lengths (3.0 m to 9.5 m) based on the actual installation distance and achieve optimal routing by combining them with the sensor's integral cable.

5. System Integration and Compatibility

The EA402 extension cable integrates seamlessly with TQ402/TQ412 transducers and the IQS900 signal conditioner:

Full Interchangeability: All components are calibrated and matched at the factory. Users can freely replace cables or sensors without affecting system performance.

Total System Length (TSL) Management: The system supports three TSLs: 1 m, 5 m, and 10 m. Users can achieve the required distance through different cable combinations. For example, a 5 m system can be achieved using a 0.5 m sensor integral cable + a 4.5 m extension cable.

Diagnostic Function Support: When paired with an IQS900 signal conditioner featuring diagnostics, the system can monitor the cable connection status in real time and indicate faults through abnormal output signals (e.g., current output out of range).

Typical Application Scenarios

Rotating Machinery Condition Monitoring: Extends sensor installation distance for vibration and displacement measurement in equipment such as gas turbines, steam turbines, and compressors.

Hazardous Area Monitoring: Certified explosion-proof versions are suitable for explosive environments like petrochemical and natural gas plants.

High-Temperature Environment Applications: Suitable for monitoring high-temperature equipment in metallurgy, energy, and other industries.

Complex Installation Scenarios: Adapts to mechanically abrasive or chemically corrosive environments using flexible stainless steel hoses or FEP sheaths.