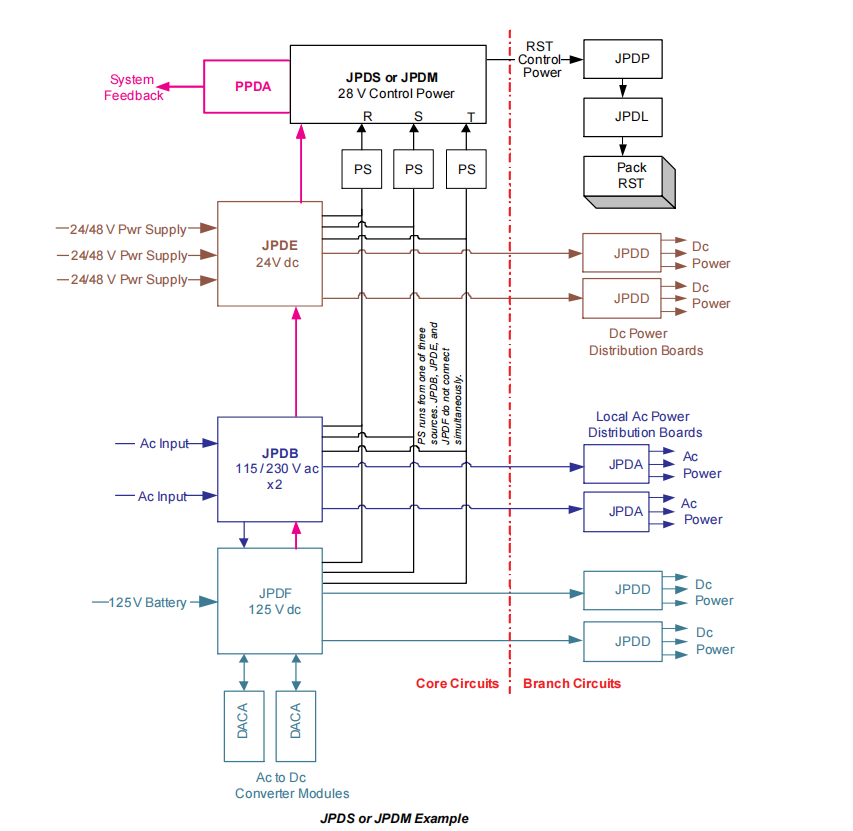

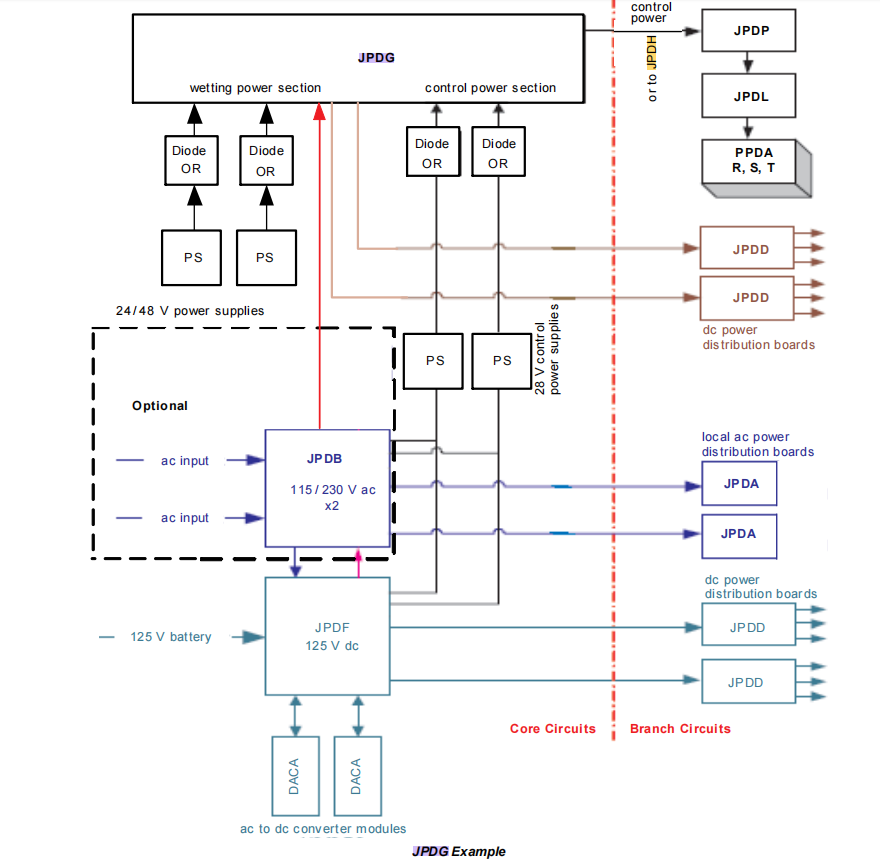

The IS200JPDHG1A (High-Density Power Distribution) board is a critical power distribution module designed by GE specifically for the Mark VIe and Mark VIeS control systems. It belongs to the Branch Circuit Board category within the PDM (Power Distribution Module) system. The primary function of the JPDH is to efficiently and reliably distribute 28 V DC control power from core power modules (such as JPDS, JPDM, JPDG, or JPDC) to numerous I/O modules and Ethernet switches within the system. Its design goal is to achieve high-density, highly reliable power distribution within a limited space, while supporting the system's Triple Modular Redundant (TMR) architecture.

The IS200JPDHG1A does not participate in system feedback (it does not connect to a PPDA I/O pack). Its design focus is on power distribution and branch circuit protection, making it particularly suitable for scenarios requiring centralized power supply for a large number of I/O modules.

2. Key Functions and Features

1. High-Density Power Output

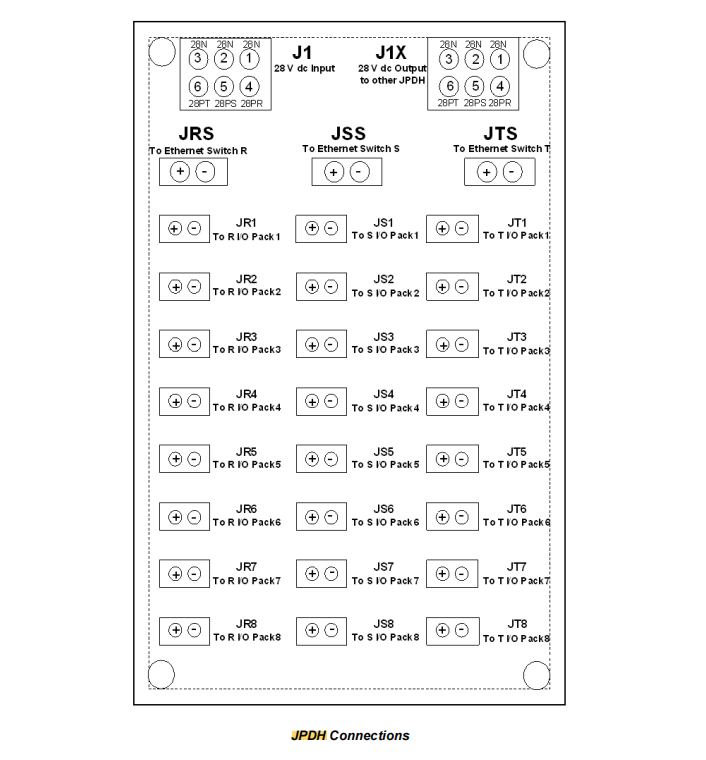

The IS200JPDHG1A board provides 24 independent 28 V DC output interfaces dedicated to powering Mark VIe I/O modules. These outputs are organized in a Triple Modular Redundancy (TMR) scheme:

Three independent power feeds: R, S, and T, with each feed supplying power to 8 I/O modules.

This architecture ensures that even if one power feed fails, the remaining two can continue to power their respective modules, significantly enhancing system availability.

2. Network Equipment Power Supply

In addition to I/O modules, the JPDH provides 3 unfused 28 V DC outputs specifically for powering the R, S, and T Ethernet switches in the system. These outputs lack fuses because switches typically have their own power management mechanisms and relatively stable power consumption.

3. Branch Circuit Protection

Each output circuit for the I/O modules is equipped with a Positive Temperature Coefficient (PTC) fuse for overcurrent protection. This type of fuse is self-resetting, automatically restoring operation after the fault is cleared, which reduces maintenance needs. Its rated current is 1.6 A @ 20°C, and it derates in high-temperature environments (e.g., 0.8 A @ 70°C), ensuring coordination with the current-carrying capacity of the connecting wires.

4. Daisy-Chain Expansion Support

The IS200JPDHG1A features a daisy-chain connection function. Via the J1X connector, multiple JPDH boards can be connected in series to collectively power systems with more than 24 I/O modules. This design greatly enhances system scalability, eliminating the need for separate core power modules for each cabinet or zone.

5. Compact Structural Design

The IS200JPDHG1A board measures 15.875 cm H × 10.795 cm W (approx. 6.25 in × 4.25 in). It can be mounted via DIN rail or base mounting, making it compact and ideally suited for high-density placement within space-constrained control cabinets.

3. Working Principle and System Integration

1. Power Input Mechanism

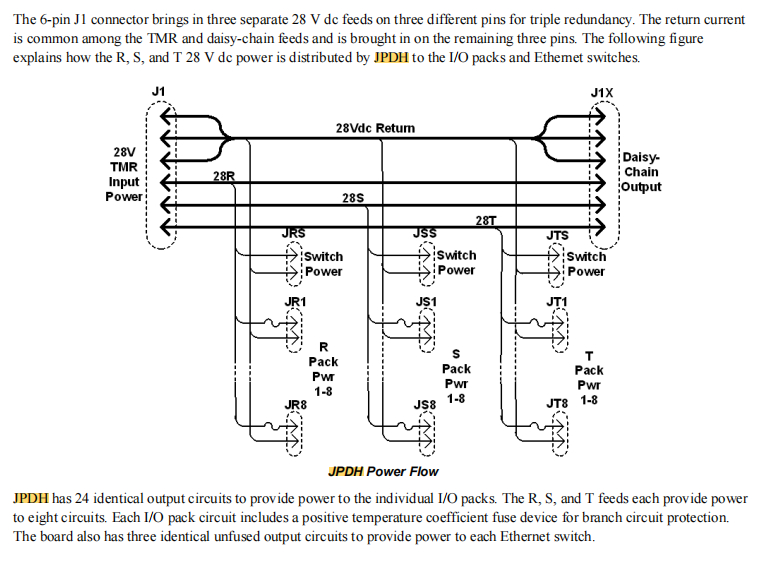

The IS200JPDHG1A receives power from upstream core power modules (like JPDS, JPDM) via a single 6-pin Mate-N-Lok connector (J1). The design of this input interface embodies the TMR concept:

Pin Assignment: 3 pins are allocated for the independent R, S, and T 28 V DC positive power feeds.

Common Ground Design: The other 3 pins serve as the common return path (ground).

Electrical Specifications: The connector is rated for 600 V, 13 A, capable of withstanding inrush current and short-term overloads during system startup.

2. Internal Power Distribution Architecture

The three input power feeds remain isolated on the board and are routed to different output groups:

R Feed → Supplies 8 I/O outputs and 1 switch output

S Feed → Supplies 8 I/O outputs and 1 switch output

T Feed → Supplies 8 I/O outputs and 1 switch output

This "separate paths" architecture is key to achieving fault isolation. A failure in any single power feed or its load will not affect the normal operation of the other two feeds.

3. Detailed Protection Mechanism

Positive Temperature Coefficient (PTC) Fuses: Their resistance increases dramatically with temperature, thereby limiting current. During an overcurrent event, the fuse heats up and "trips" into a high-resistance state, limiting the current to a safe value. Once the fault is cleared and the temperature drops, its resistance recovers, and the circuit returns to normal automatically. This protection method requires no component replacement, making it particularly suitable for remote or hard-to-maintain industrial sites.

Coordinated Protection: The selection of the PTC fuses is coordinated with the specifications of the downstream cables, ensuring that in an overcurrent situation, the fuse acts before the cable is compromised, providing true "branch circuit protection."

4. Daisy-Chain Working Principle

When a single IS200JPDHG1A cannot meet the power requirements of all I/O modules, power (including the R, S, T feeds and their common ground) can be routed from its J1X output connector to the J1 input connector of the next JPDH board. It is crucial to note that in this mode, the user must provide suitable upstream branch circuit protection for the entire daisy chain, as the input protection of the first JPDH cannot protect loads on subsequent boards in the series. The total current must be calculated during design to ensure it does not exceed the capacity of the upstream power source and cabling.

4. Installation and Mechanical Characteristics

Mounting Method: IS200JPDHG1A can be mounted vertically on a metal backplate or bracket within the control cabinet using #6 machine screws through the four corner mounting holes. It also supports standard DIN rail mounting, offering layout flexibility.

Connectors: All power input and output interfaces use the Mate-N-Lok series connectors, known for secure connection, prevention of mis-mating, and high current-carrying capacity.

Environmental Compatibility: Its operating temperature range is -40°C to +70°C, with a humidity range of 5% to 95% (non-condensing), meeting the demands of harsh industrial environments.

5. Application Scenarios and System Example

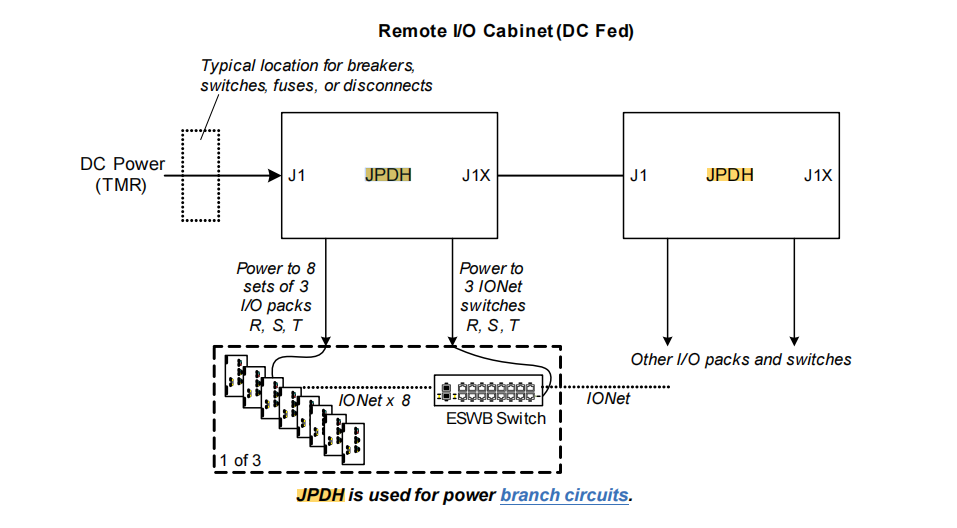

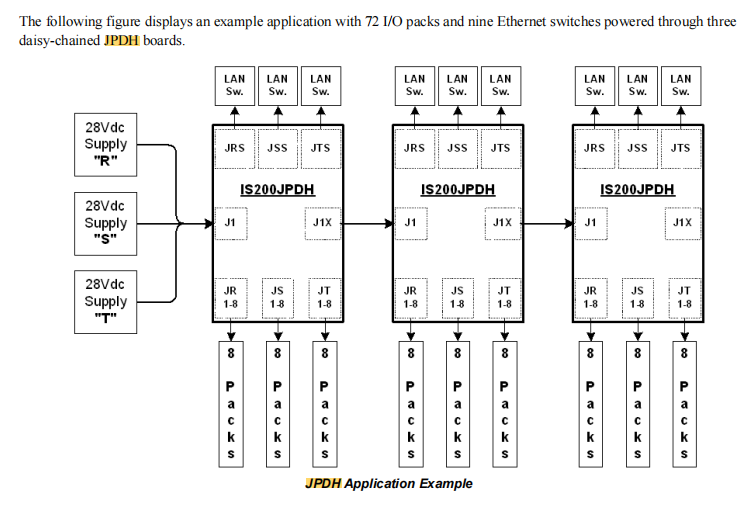

The IS200JPDHG1A is typically used in remote I/O cabinets or large control systems requiring centralized power supply. A system comprising 72 I/O modules and 9 Ethernet switches can be effectively powered by connecting 3 JPDH boards in a daisy-chain configuration.

Each IS200JPDHG1A is responsible for 24 I/O modules and 3 switches. Together, the three boards form a complete, redundant, and protected power distribution network. This fully demonstrates the powerful capability of the JPDH in building highly reliable, high-density control systems.