The MPC4 Machinery Protection Card is a core component of VM product line and a key part of the VM600 series Machinery Protection System (MPS). Designed for the real-time monitoring and protection of industrial machinery, this card features high programmability and versatility, capable of simultaneously processing four dynamic signal inputs and two tachometer (Keyphasor) inputs. The MPC4 card is widely used in critical industrial sectors such as power generation, oil & gas, and aerospace to ensure equipment operates under safe and reliable conditions.

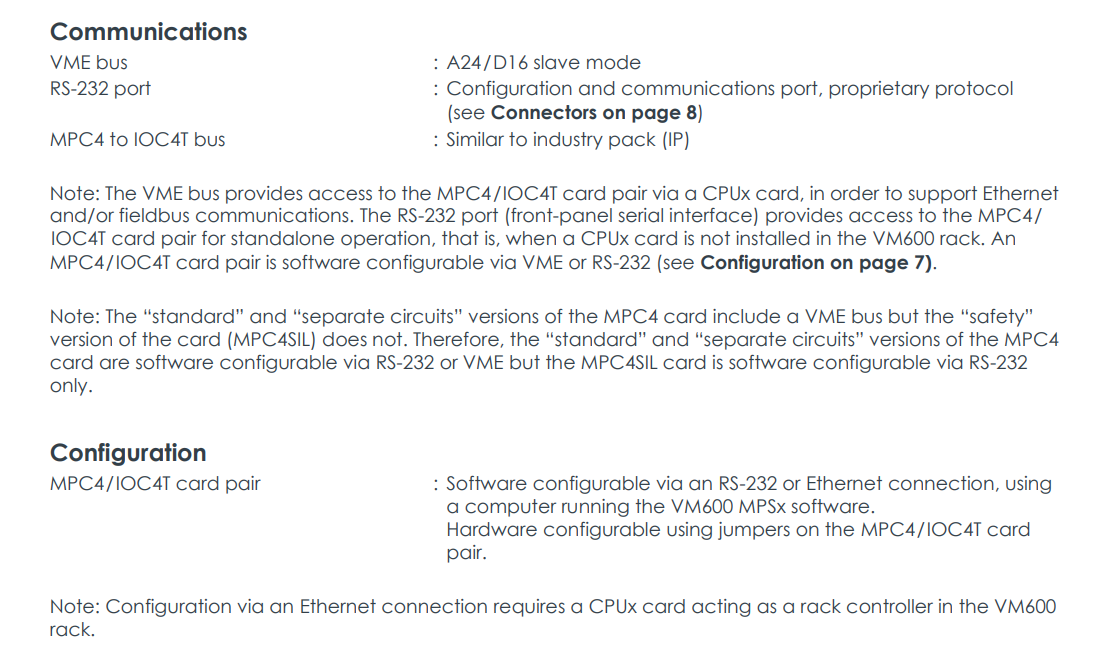

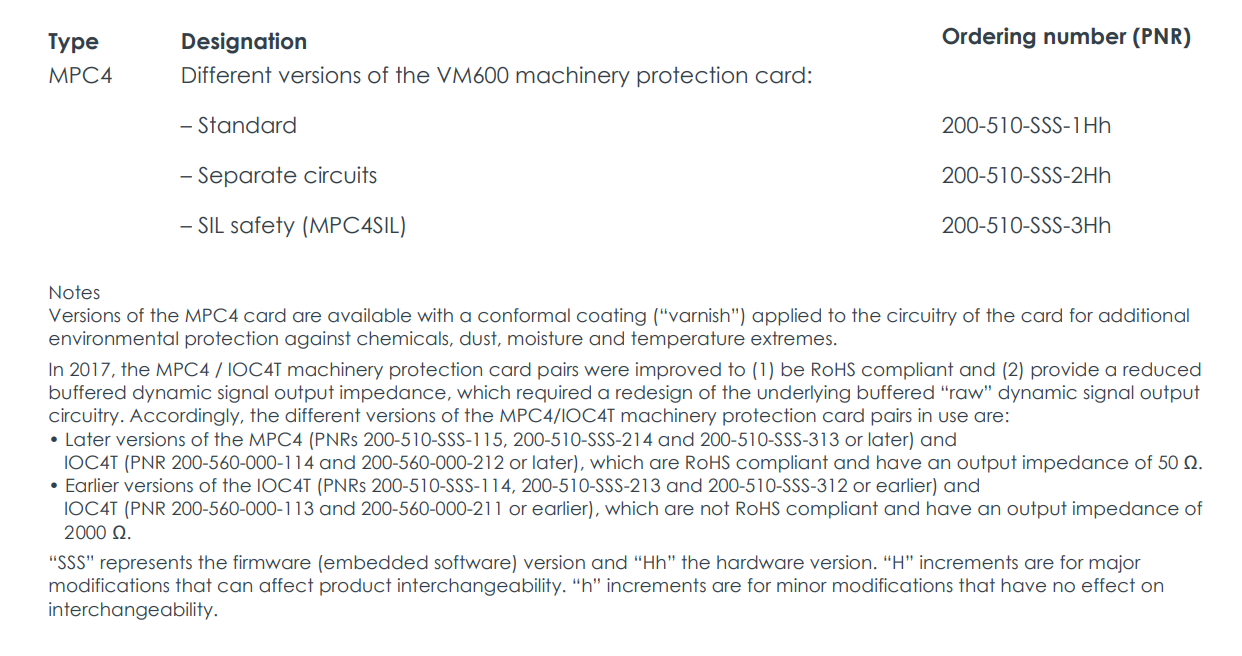

The MPC4 card is available in three versions: Standard, Separate Circuits, and Safety (MPC4SIL), meeting the safety and functional requirements of different application scenarios. All versions must be used as a card pair with a corresponding IOC4T input/output card.

II. Key Features & Benefits

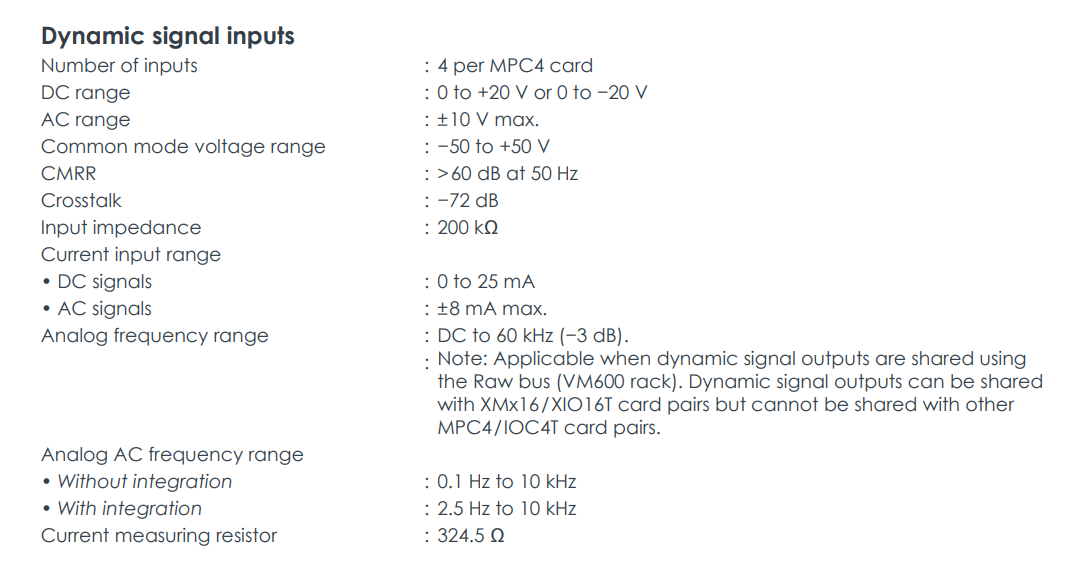

1. Multi-Channel Dynamic Signal Input

Supports 4 dynamic signal channels, accepting inputs from various sensors such as acceleration, velocity, and displacement (proximity).

Each channel is independently programmable and supports voltage (±10V AC) or current (0–25mA DC) input.

Input impedance is 200 kΩ, with high Common-Mode Rejection Ratio (>60 dB) and low crosstalk (-72 dB).

2. Dual Tachometer (Keyphasor) Input

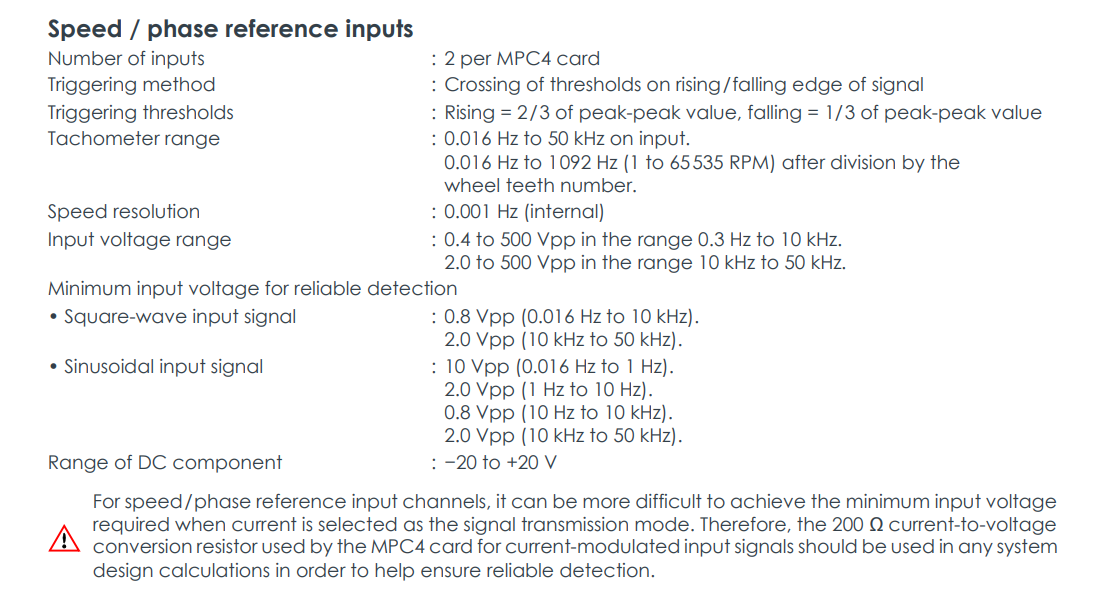

Supports 2 speed/phase reference inputs, suitable for proximity probes, magnetic pickups, or TTL signals.

Supports fractional tachometer ratios, with a wide speed range (0.016 Hz to 50 kHz).

3. Real-Time Digital Signal Processing (DSP)

Utilizes advanced DSP technology for real-time filtering, integration/differentiation, and rectification (RMS, mean, true peak, true peak-to-peak).

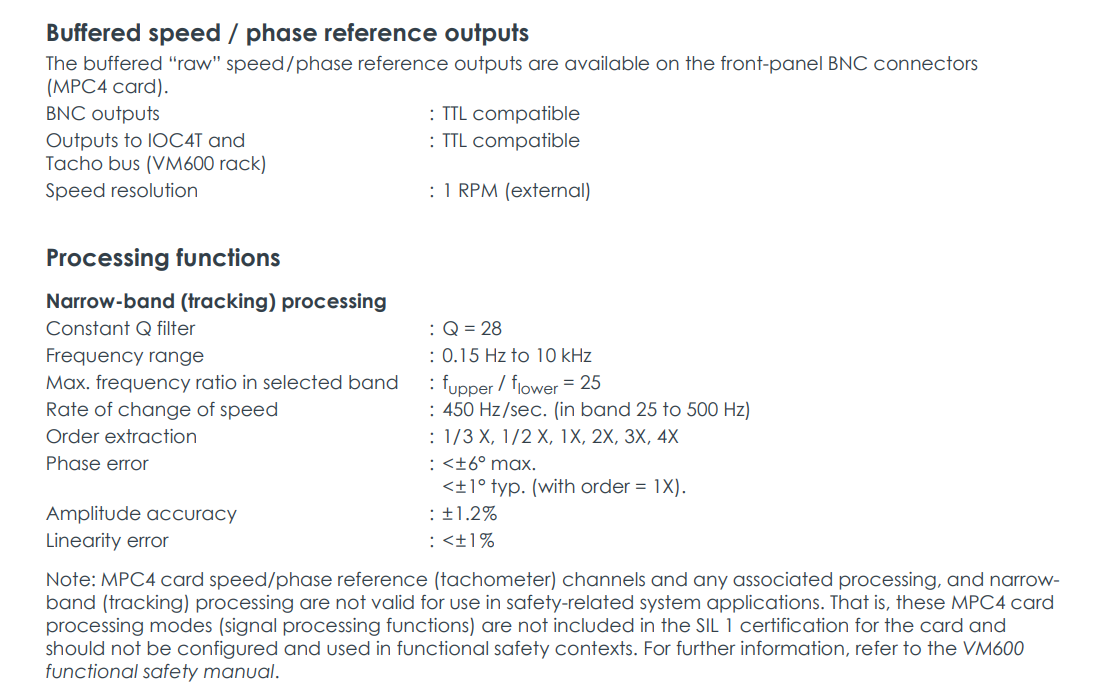

Supports order tracking, allowing simultaneous monitoring of amplitude and phase.

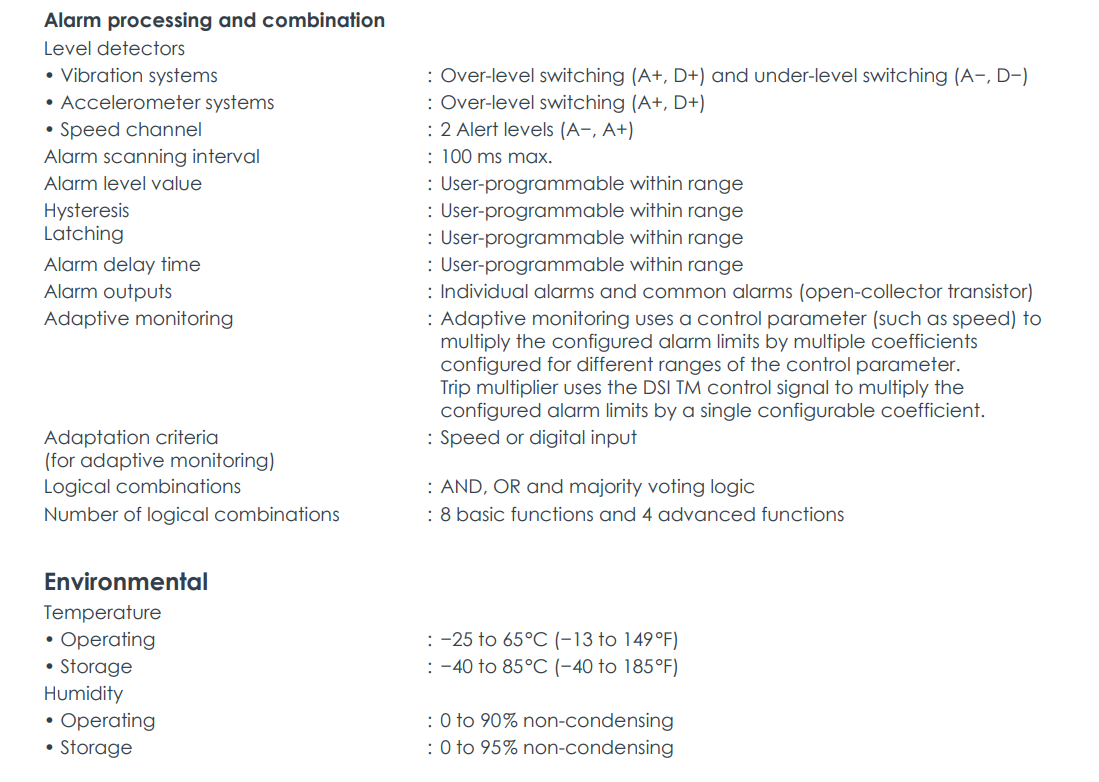

4. Programmable Alarms & Adaptive Setpoints

Provides Alert and Danger two-level alarms, supporting delay, hysteresis, and latching functions.

Alarm thresholds can be adaptively adjusted based on speed or external signals, enhancing system flexibility.

5. Sensor Power Supply & Signal Conditioning

Integrated power supplies support sensors like IEPE accelerometers and proximity measurement systems.

Provides ±27.2V, +15V voltage outputs, and a 6.16 mA constant current source.

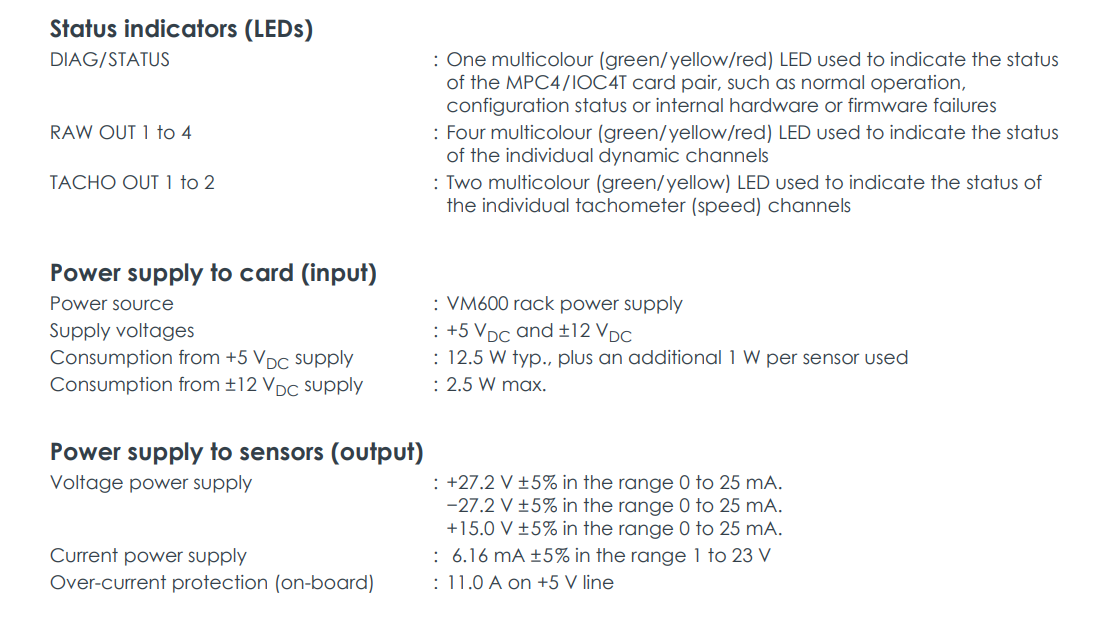

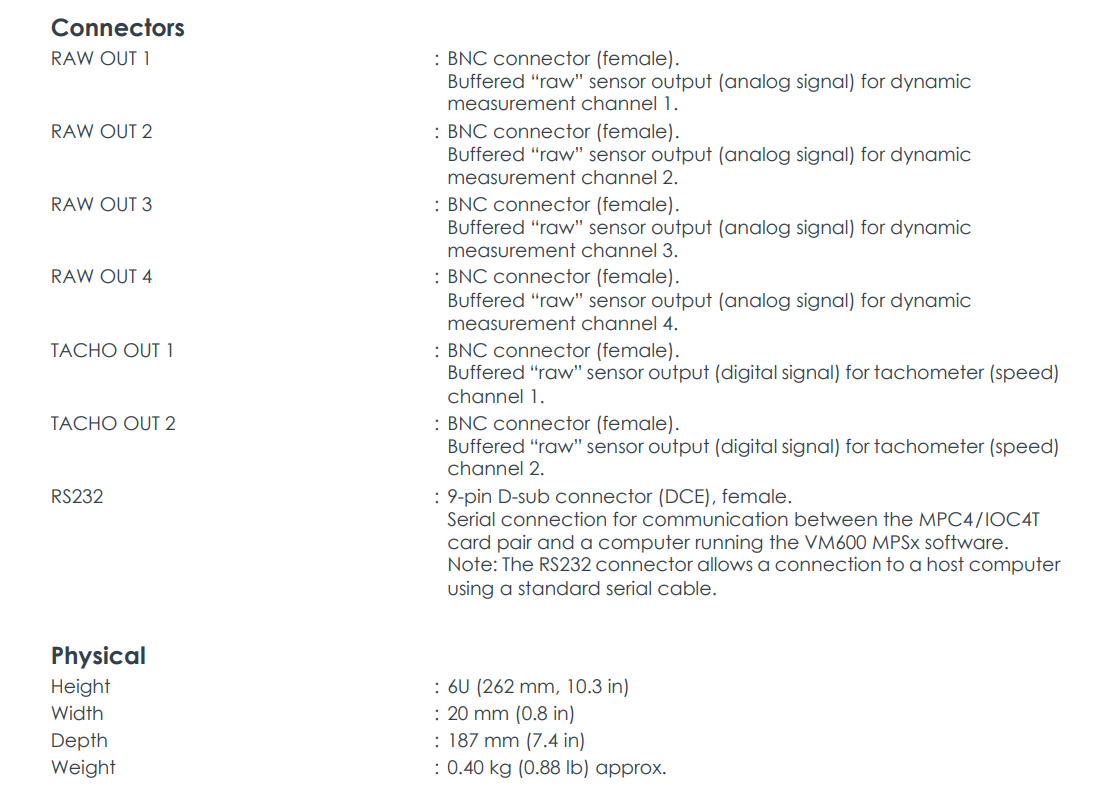

6. Front-Panel Connectors & Status Indicators

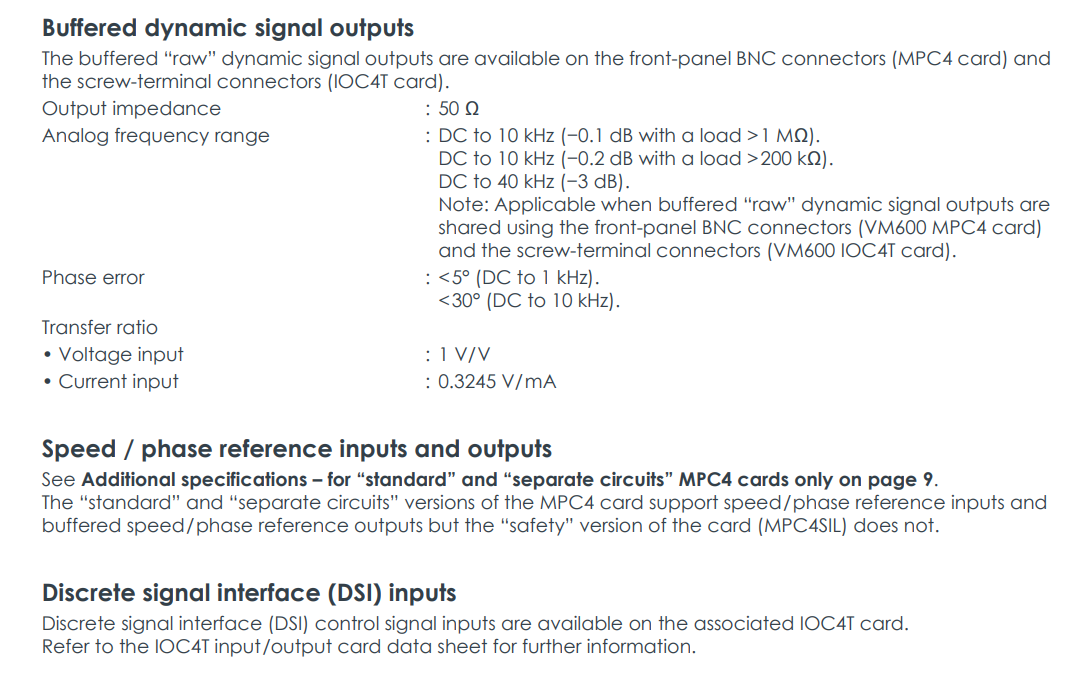

BNC connectors for each channel output buffered "raw" sensor signals for external analysis.

Front-panel LED indicators display channel status, alarms, and system faults.

7. Hot-Swappable & Modular Design

Supports live insertion and removal (hot-swapping), facilitating maintenance and upgrades.

Can operate in conjunction with other cards in the VM600 system (e.g., IOC4T, RLC16, IRC4).

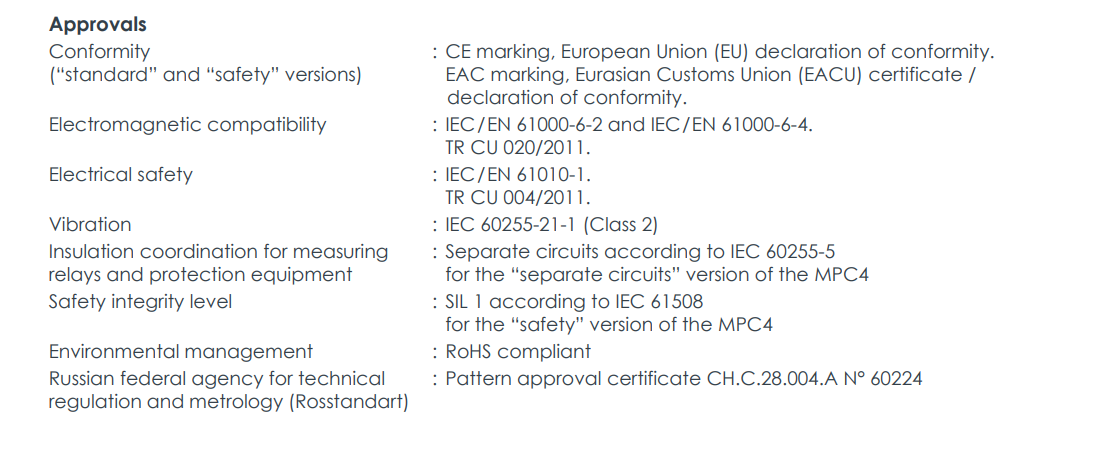

8. Safety & Certifications

Both Standard and Safety versions are certified to IEC 61508 and ISO 13849 for functional safety systems (e.g., SIL 1, PL c).

The Safety version (MPC4SIL) features electrical isolation to prevent inadvertent configuration changes.

III. Working Principle & Processing Functions

The core operating principle of the MPC4 card is based on high-performance Digital Signal Processing (DSP) technology. It provides comprehensive machinery monitoring and protection through real-time acquisition, filtering, analysis, and alarm processing of sensor signals. The working principle is detailed in four aspects below:

1. Signal Input & Conditioning

The MPC4 card accepts signals from various sensors, including:

Dynamic Signals: Such as vibration acceleration, velocity, displacement, as well as thrust position, eccentricity, case expansion, etc.

Tachometer Signals: From Keyphasors, encoders, or pulse sensors, used for phase reference and speed measurement.

Each dynamic signal input undergoes analog front-end conditioning, including:

Impedance Matching: 200 kΩ input impedance accommodates various sensor output characteristics.

Common-Mode Rejection: CMRR > 60 dB effectively suppresses common-mode interference.

Frequency Response: Analog frequency range from DC to 60 kHz (-3 dB), ensuring high-frequency components are preserved.

Current input signals are converted to voltage signals via an internal 324.5 Ω resistor before sampling. All input signals pass through anti-aliasing filters before reaching the ADC (Analog-to-Digital Converter), ensuring sampling accuracy.

2. Digital Signal Processing Flow

The MPC4 card uses a multi-channel parallel processing architecture, where each signal is processed independently, primarily involving the following steps:

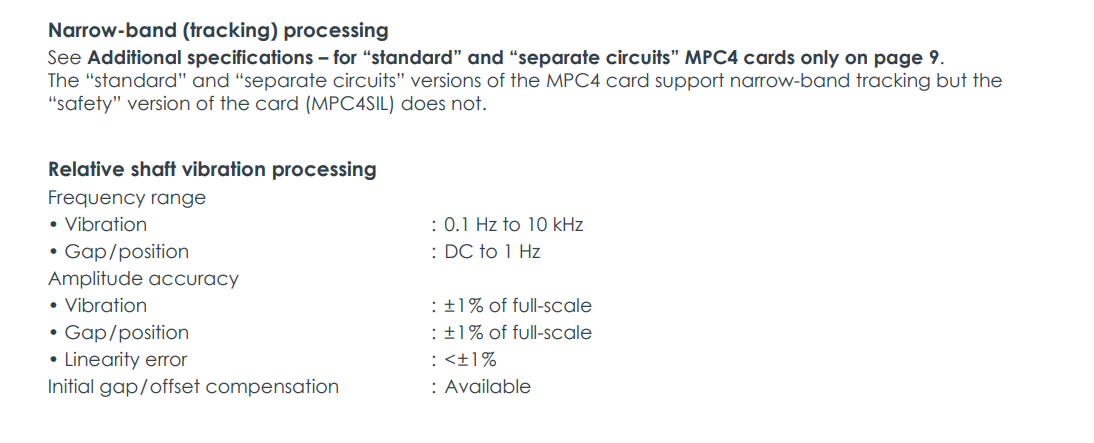

a) Digital Filtering

Supports high-pass, low-pass, and band-pass filters with configurable slopes from 6 to 60 dB/octave.

Passband ripple is less than ±0.3 dB, and stopband attenuation is greater than 50 dB, ensuring signal purity.

b) Integration & Differentiation

Can integrate acceleration to velocity or displacement, or differentiate velocity to acceleration, as required.

Integration operational frequency range is 2.5 Hz to 10 kHz.

c) Rectification & Amplitude Calculation

Supports multiple amplitude calculation methods:

RMS (Root Mean Square)

Mean Value

True Peak

True Peak-to-Peak

Linearity error is less than ±1%, and amplitude accuracy is ±1% of full scale.

d) Order Tracking & Phase Analysis

Automatically tracks the amplitude and phase of specific orders (e.g., 1X, 2X, 3X) during speed changes.

Phase error is less than ±6°, typically ±1° at the fundamental frequency.

e) Gap/Position Measurement

3. Alarm Processing & Logic Combination

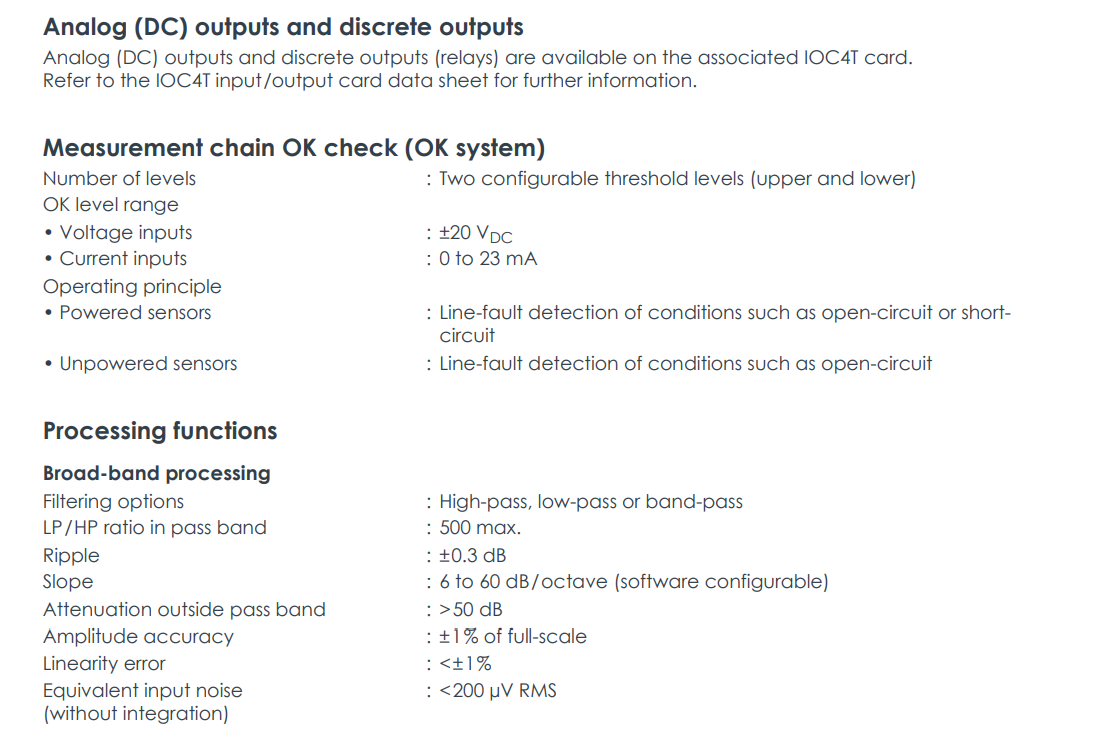

The MPC4 card features a flexibly configurable alarm system:

a) Alarm Levels

Each channel supports Alert and Danger two-level alarms, each configurable as over-limit (A+, D+) or under-limit (A-, D-).

Alarm thresholds can be set anywhere within the full scale and support adaptive adjustment, e.g., based on speed.

b) Alarm Delay & Hysteresis

c) Logic Combinations

Supports logic combinations such as AND, OR, and Majority Voting, with up to 8 basic functions and 4 advanced functions configurable.

Suitable for complex multi-parameter judgment in machinery systems.

d) Alarm Outputs

Alarm signals are output via the IOC4T card, driving relays or transmitting via the OC bus to other cards (e.g., RLC16, IRC4).

4. System Self-Diagnostics (OK System)

The MPC4 card includes a built-in OK System that continuously monitors the health of the sensor and signal chain:

Two-Level Threshold Detection: Configurable upper and lower limits monitor whether the signal level is within a reasonable range.

Line Fault Detection: Identifies faults such as open circuits and short circuits.

Front-Panel Indication: Each channel has an LED indicating the "OK" status or fault type.

Additionally, the MPC4 card performs a self-test routine upon startup, diagnosing hardware and firmware status to ensure reliable system operation.

IV. Version Differences & Applicable Scenarios

| Version | Characteristics | Typical Applications |

| Standard | Supports all features, including VME bus, tachometer channels, narrowband tracking. | General machinery protection systems. |

| Separate Circuits | Electrically isolated design, compliant with IEC 60255-5. | High electromagnetic interference environments. |

| Safety (MPC4SIL) | No VME interface, no tachometer or narrowband tracking support, SIL 1 certified. | Functional safety systems (e.g., SIL 1 / PL c). |

V. Typical Applications

Gas & Steam Turbines: Vibration, displacement, speed monitoring.

Compressors & Pumps: Shaft vibration, bearing condition, thrust position.

Generators & Motors: Vibration protection, phase analysis.

Wind Turbines: Drive train vibration and speed tracking.