The 3500/45 Position Monitor is a highly specialized, multi-functional, and rugged position monitoring module within the Bently Nevada 3500 Series Machinery Condition Monitoring System. As a four-channel monitor, its core design objective is to accurately measure and monitor the mechanical position changes of critical components in rotating machinery, providing vital protection for predictive maintenance and preventing catastrophic mechanical failures.

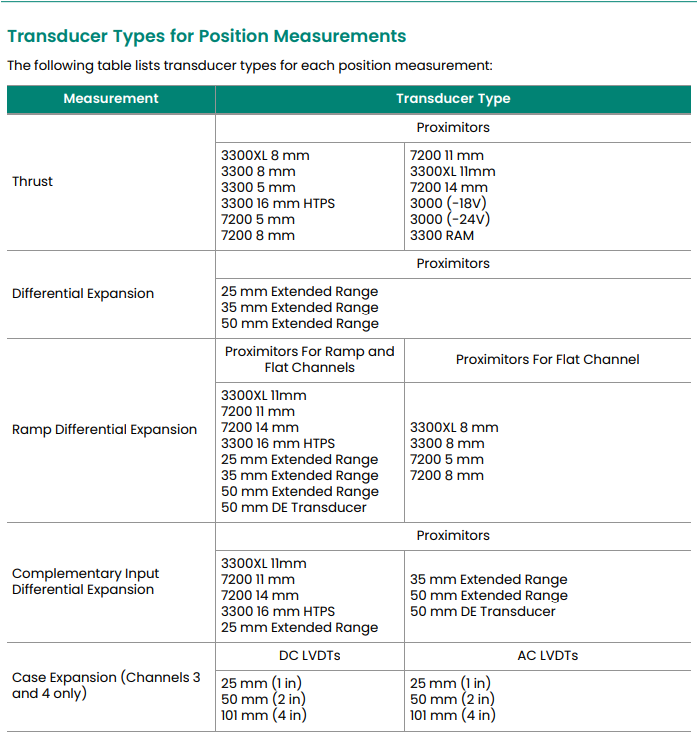

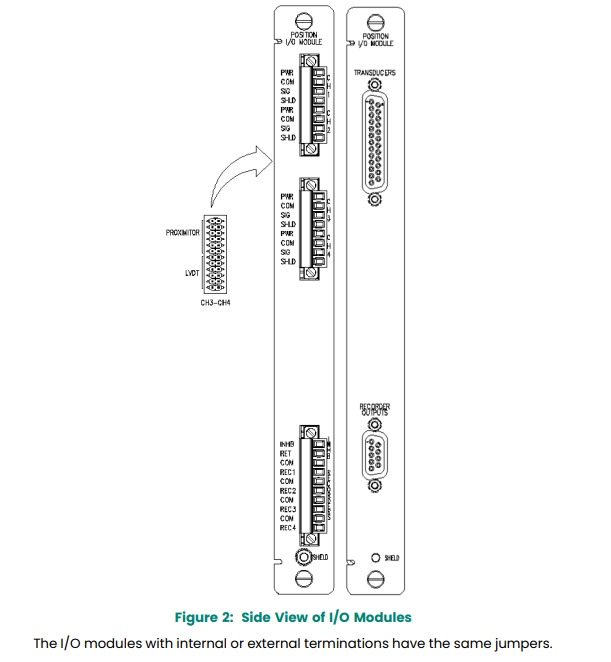

The monitor's excellence lies in its unparalleled sensor compatibility. It can directly receive and process signals from various position sensors, including:

Proximity Transducers

Rotary Position Transducers

DC Linear Variable Differential Transformers

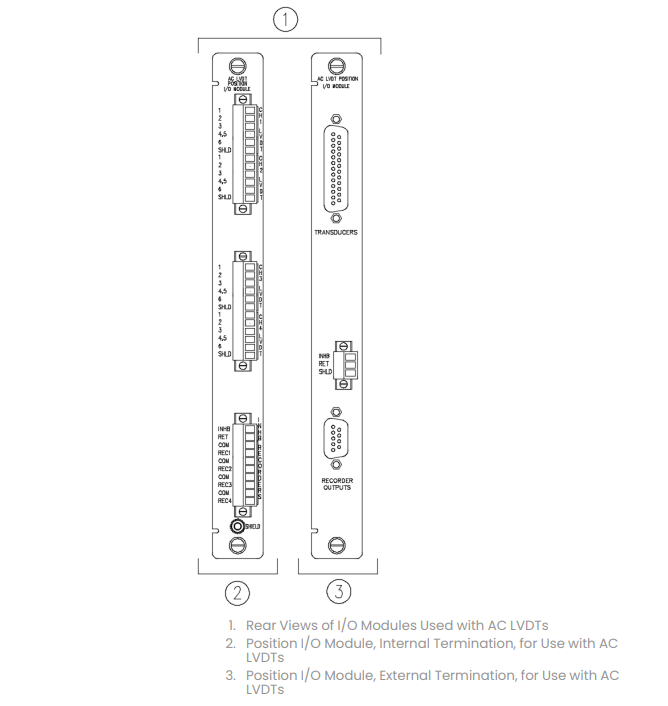

AC Linear Variable Differential Transformers

Rotary Potentiometers

This extensive compatibility allows the 3500/45 to meet diverse and complex position monitoring needs, from traditional turbomachinery to modern process industry valves.

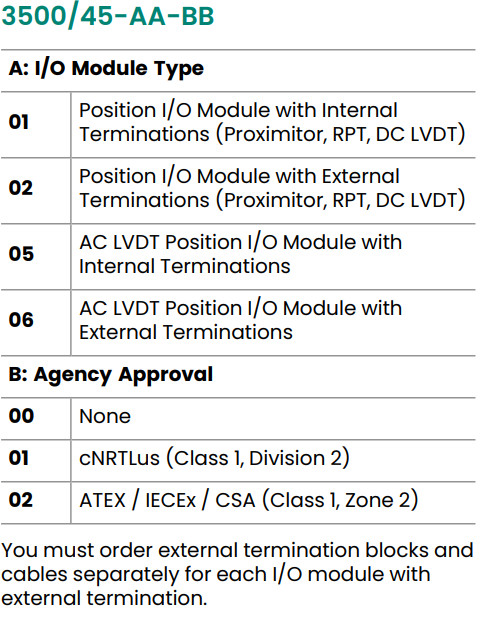

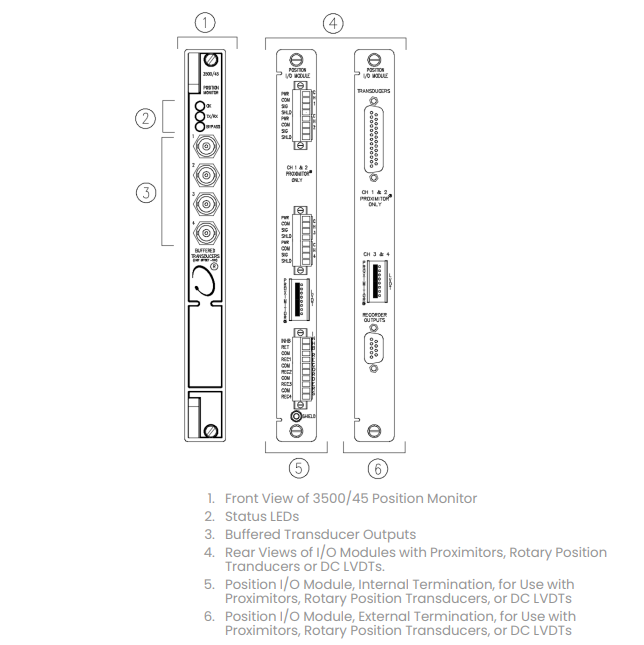

Using the 3500 Rack Configuration Software, users can configure each channel to perform several key functions, including: Axial (Thrust) Position, Differential Expansion, Standard Single Ramp Differential Expansion, Non-Standard Single Ramp Differential Expansion, Dual Ramp Differential Expansion, Complementary Input Differential Expansion (CIDE), Case Expansion, and Valve Position. The monitor's four channels are configured and managed in "Channel Pairs," allowing a single module to perform two different monitoring functions simultaneously.

2. Core Features and Detailed Functional Principles

2.1 Core Function: Multi-Sensor Interface and Precision Position Measurement

The core value of the 3500/45 is its integration of multiple sensor technologies into a unified platform, coupled with high-precision signal conditioning and calculation.

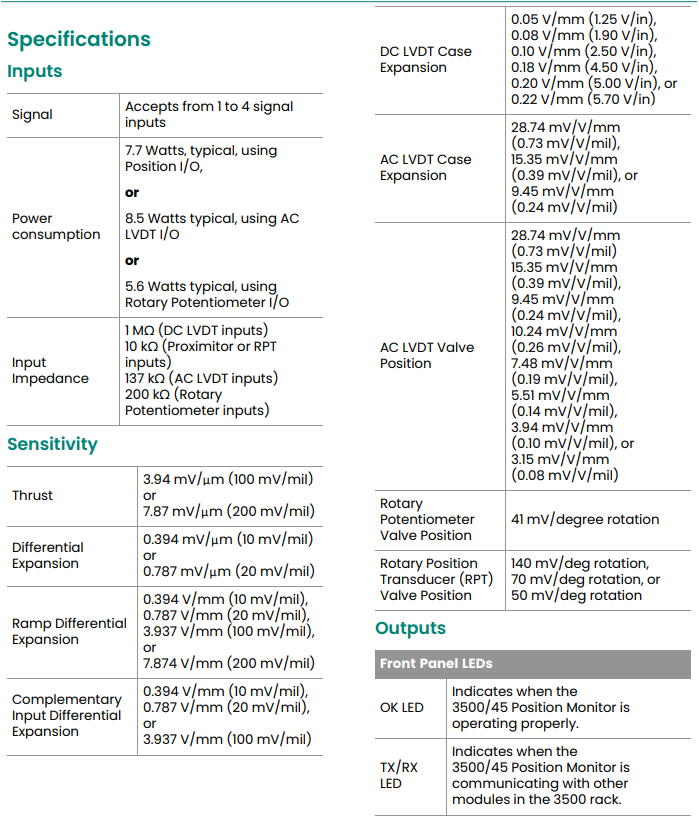

Multi-Sensor Interface and Power Supply: The monitor provides dedicated power supplies and signal conditioning circuits for different sensor types:

Proximity Transducers / RPTs: Supplies -24 Vdc excitation power, with an input impedance of 10 kΩ.

DC LVDTs: Supplies +15 Vdc excitation power, with an input impedance of 1 MΩ.

AC LVDTs: Supplies 2.3 Vrms, 3400 Hz sine wave excitation, with an input impedance of 137 kΩ.

Rotary Potentiometers: Supplies -12.38 Vdc excitation power, with an input impedance of 200 kΩ.

This targeted design ensures each sensor type operates under its optimal conditions, yielding the most accurate raw signals.

Signal Conditioning and Filtering: All position signals undergo precise conditioning. The module incorporates Direct and Gap filters with cutoff frequencies of 1.2 Hz and 0.41 Hz, respectively. These low-pass filters effectively remove high-frequency electrical noise and mechanical vibration interference, ensuring the extraction of true DC and low-frequency AC signals reflecting slow mechanical displacement, which is crucial for tracking slow processes like thermal expansion.

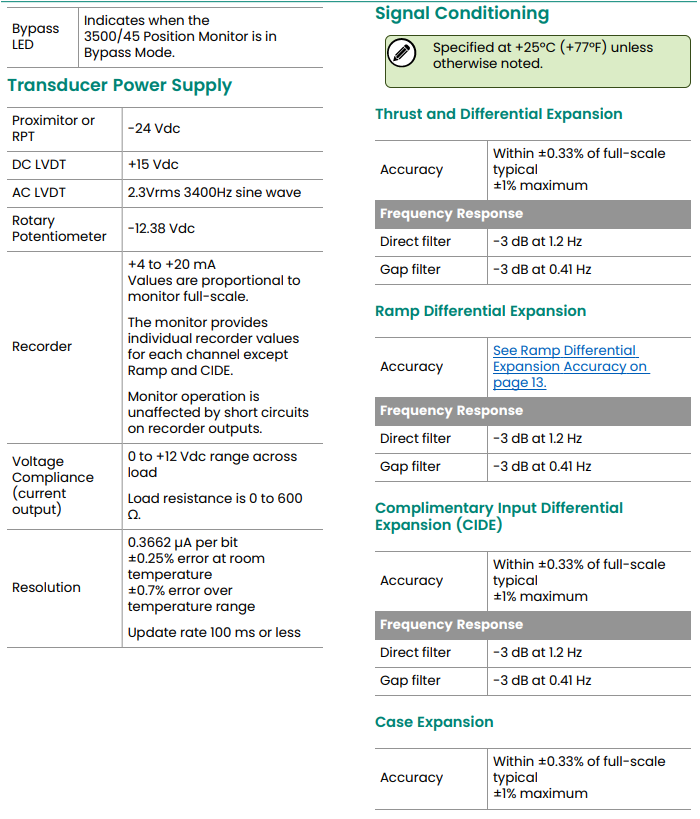

Measured Variables and Alarms: The conditioned signals are calculated into Measured Variables. Users can set Alert alarms for each active variable and select any two of the most critical variables for Danger alarms. The accuracy of the alarm setpoints is within ±0.13% of the desired value. Programmable alarm time delays further prevent false alarms.

Recorder Outputs: Each channel (except Ramp DE and CIDE) provides an independent 4-20 mA Recorder Output for connection to DCS or recording devices, enabling continuous data logging and monitoring.

2.2 Key Monitoring Functions: Working Principles and Mechanical Significance

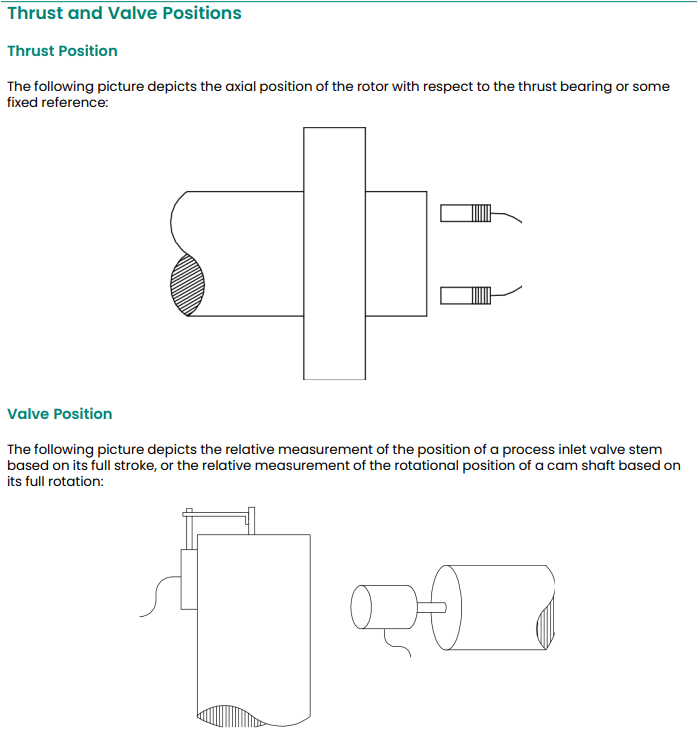

a) Axial (Thrust) Position Monitoring

Principle: Precisely measures the axial displacement of the rotor using proximity transducers installed near the thrust bearing. The monitor measures the average gap voltage of the transducer.

Mechanical Significance: Used to prevent axial rubbing between the rotor and stationary components in rotating machinery (e.g., steam turbines, compressors). When the rotor moves due to thrust unbalance, the monitor promptly triggers alarms, protecting the expensive thrust bearing and the entire rotor train. Its typical sensitivity is 3.94 mV/μm or 7.87 mV/μm.

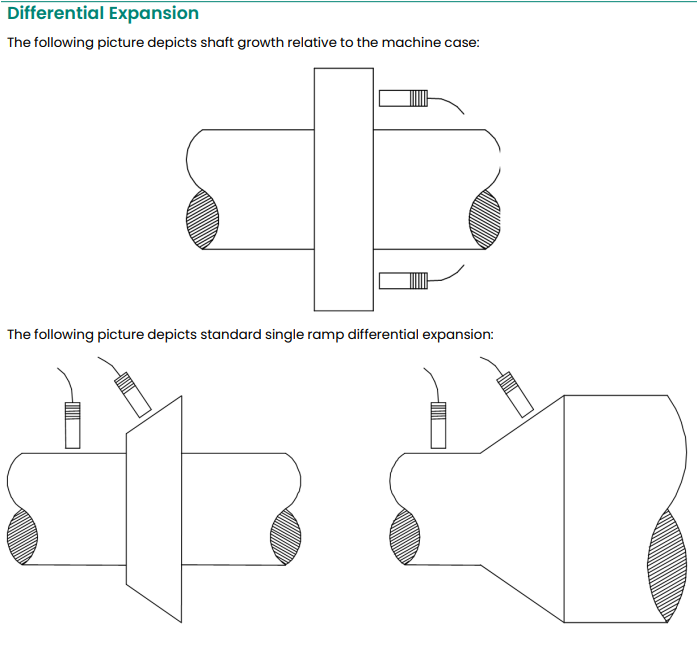

b) Differential Expansion Monitoring

Differential Expansion is one of the most critical monitoring parameters for large rotating machinery (especially steam turbines), referring to the difference in thermal expansion between the rotor and the casing due to differences in mass, material, and heating.

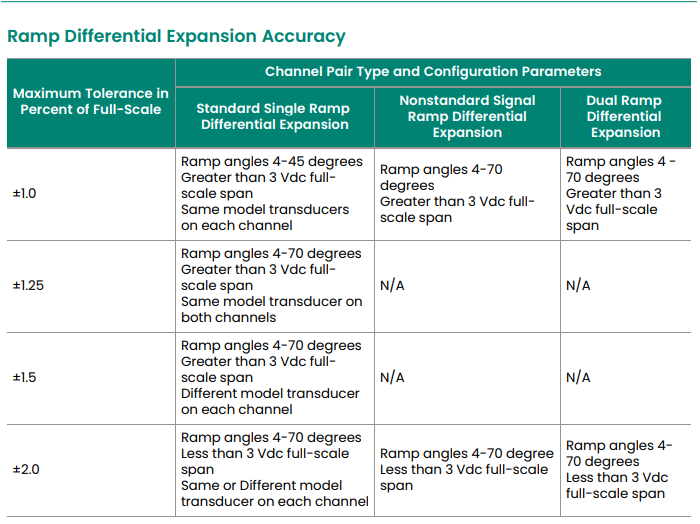

Standard Single Ramp DE: Uses one proximity transducer aimed at a ramped surface on the rotor. As the rotor expands, the relative position between the transducer and the ramp changes, causing a linear change in output voltage. The monitor converts this voltage into an expansion value.

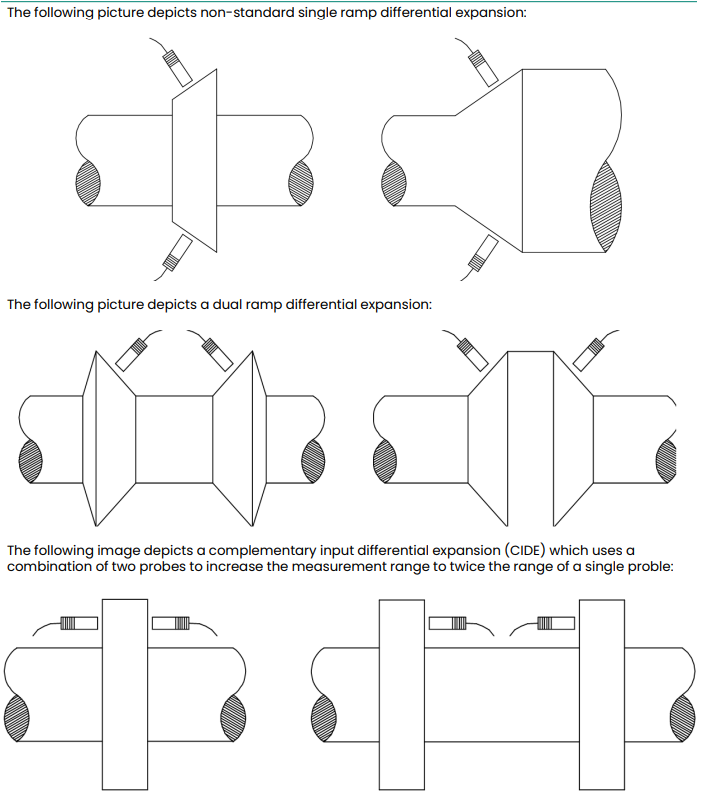

Non-Standard Single Ramp DE: Similar principle but allows for more flexible ramp angle configuration.

Dual Ramp DE: Uses two transducers monitoring two different ramped surfaces, providing a wider measurement range or redundancy.

Complementary Input DE (CIDE): This is an advanced feature of the 3500/45. It uses two transducers aimed at the same measurement plane on the rotor but installed on opposite sides. By combining the signals from both transducers using internal algorithms, the effective measurement range can be doubled compared to a single transducer. This is particularly important for units with very large expansion during startup and coastdown, ensuring seamless monitoring throughout the entire cycle.

Accuracy: The accuracy of Ramp DE depends on the ramp angle and full-scale voltage span, reaching ±1.0% of full scale under optimal conditions.

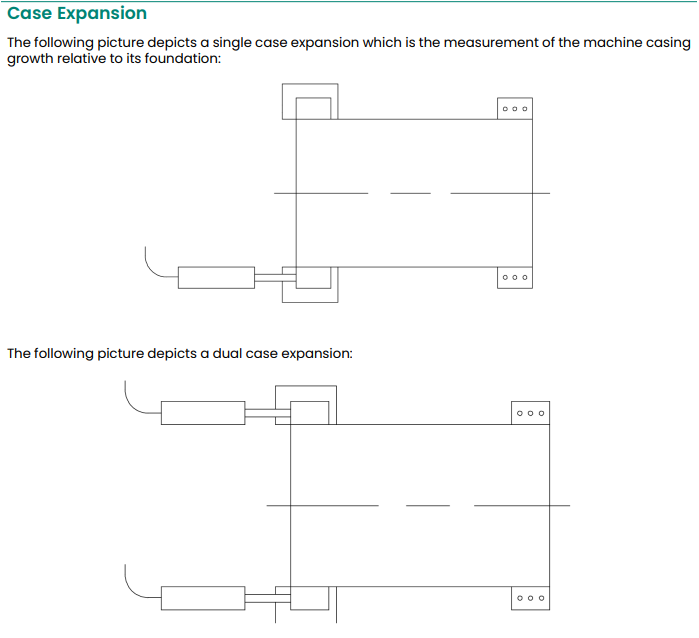

c) Case Expansion Monitoring

Principle: Uses DC LVDTs or AC LVDTs to measure the thermal expansion of the machine casing relative to its foundation.

Mechanical Significance: Combined with differential expansion data, case expansion data provides a more comprehensive assessment of the overall thermal behavior of the rotor and casing. It is key for diagnosing faults such as binding in the sliding key system or excessive pipe stress.

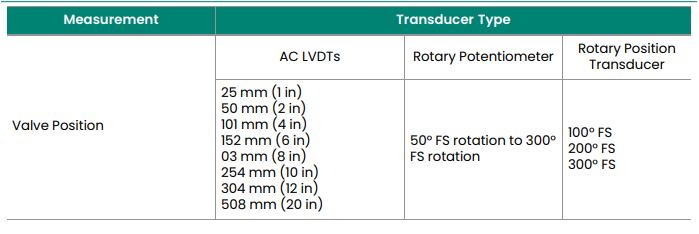

d) Valve Position Monitoring

Principle: Uses RPTs, Rotary Potentiometers, or AC LVDTs to measure the linear travel of a control valve stem or the rotational position of an actuator based on its full stroke or rotation.

Mechanical Significance: Used in process industries to monitor the opening of critical valves, ensuring precise process control and diagnosing issues like valve sticking or hysteresis.

2.3 Accuracy and Performance Assurance

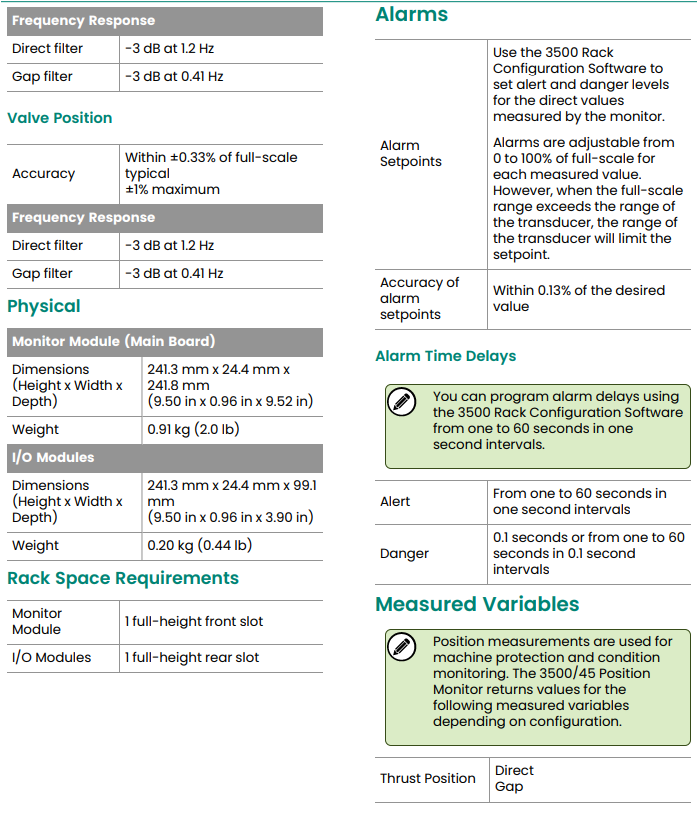

The 3500/45 delivers exceptional measurement accuracy. At +25°C, for most measurements, the typical accuracy is ±0.33% of full scale, with a maximum of ±1% of full scale. The module's power consumption varies depending on the I/O module type used, typically between 5.6 Watts and 8.5 Watts, reflecting an efficient design.

3. Hardware Architecture and Configuration

4. Environmental Suitability, Compliance, and Certifications

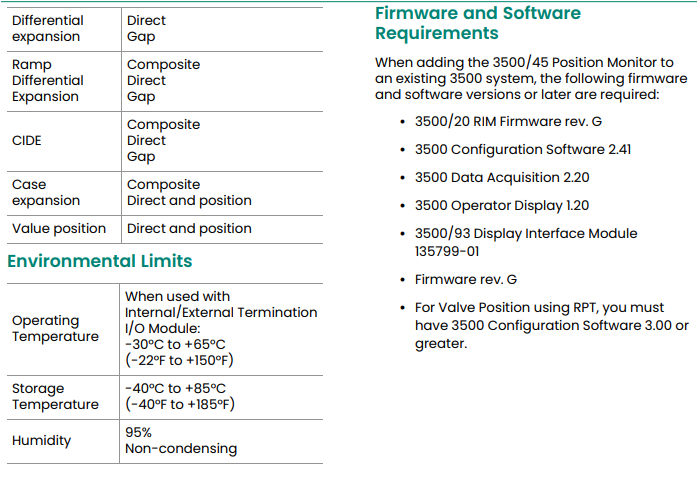

The 3500/45 is designed for harsh industrial environments:

Operating Temperature: -30°C to +65°C when used with standard I/O modules.

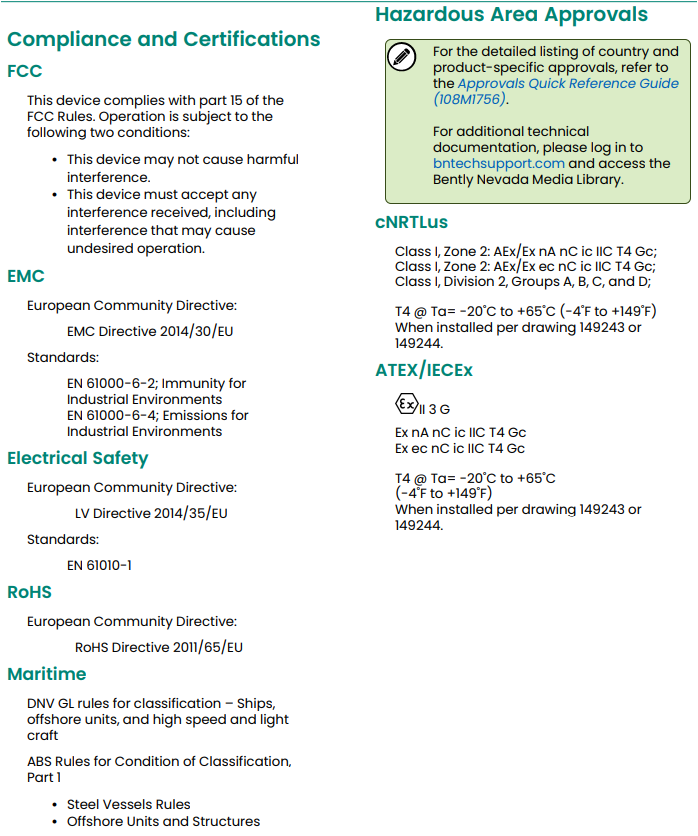

Certifications: Complies with FCC, EMC Directive, Low Voltage Directive, RoHS Directive, and holds marine certifications from DNV GL and ABS. When used with I/O modules with internal barriers, it can also meet hazardous area standards like cNRTLus, ATEX, and IECEx.

5. Application Scenarios

The 3500/45 Position Monitor is a cornerstone for the following critical applications:

Power Generation: Thrust bearing, differential expansion, and case expansion monitoring in steam turbines and gas turbines.

Oil & Gas: Axial position monitoring in large compressors and pumps.

Chemical and Process Industries: Valve position monitoring for critical control valves.

Any heavy industrial environment requiring precise monitoring of mechanical position, expansion, and displacement.