The 3500/92 Communication Gateway is a high-performance communication module under the 3500 Machinery Protection Systems, specifically designed for machinery condition monitoring systems in industrial environments. As a critical component of the 3500 series, this module provides robust communication interface capabilities, supporting multiple industrial protocols. It efficiently and reliably transmits monitored data, status information, and alarm information from all modules within the chassis to upper-level control systems or data acquisition platforms. Its design meets industrial-grade environmental requirements, boasts extensive certifications and adaptability, and is suitable for various sectors such as power, petrochemical, maritime, and manufacturing.

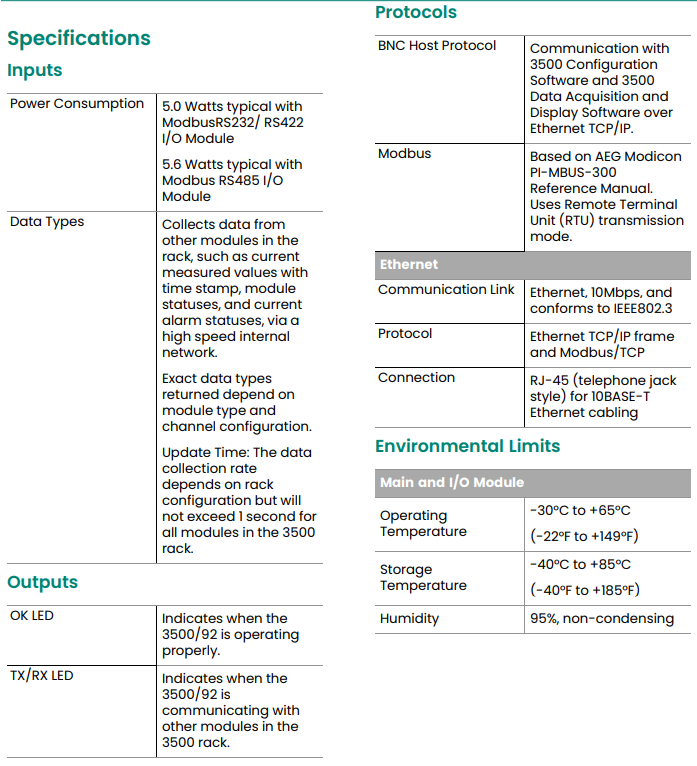

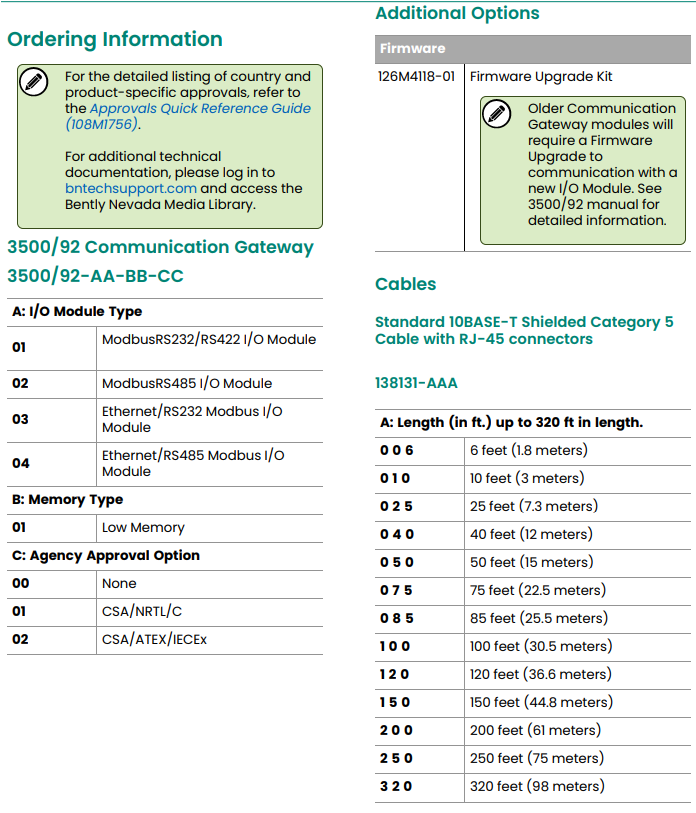

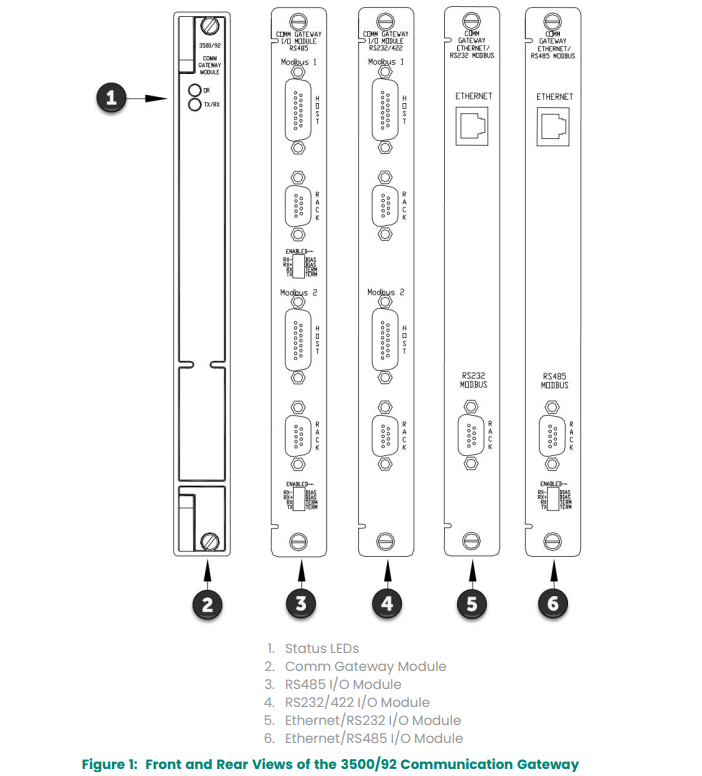

The 3500/92 consists of a fixed front card (136180-01) and four different types of rear cards (details can be found on the Ordering page). The 136180-01, combined with any one rear card, forms a complete system.

Key Features and Functions

1. Multi-Protocol Communication Support

The 3500/92 supports the following three mainstream industrial communication protocols:

Modicon Modbus Protocol: Implemented via RS232/RS422/RS485 serial interfaces, it is suitable for integration with traditional PLC and DCS systems. It supports RTU (Remote Terminal Unit) mode, where data is transmitted in a compact binary format, offering high efficiency and strong error detection capabilities, making it ideal for use in noisy industrial environments.

Modbus/TCP Protocol: A variant of serial Modbus based on Ethernet TCP/IP, it supports higher data transmission rates and is suitable for modern automation networks. It allows simultaneous multi-client access through standard network infrastructure, greatly enhancing system scalability and integration flexibility.

Bently Nevada Proprietary Protocol: Used for communication with the 3500 Rack Configuration Software and Data Acquisition Software, enabling configuration management, real-time data monitoring, and historical data recording. This protocol is deeply optimized for the Bently Nevada product series, offering rich features including module parameter configuration, real-time data streaming, and diagnostic information access, making it key to deep system integration and efficient maintenance.

2. Dual Communication Interface Design

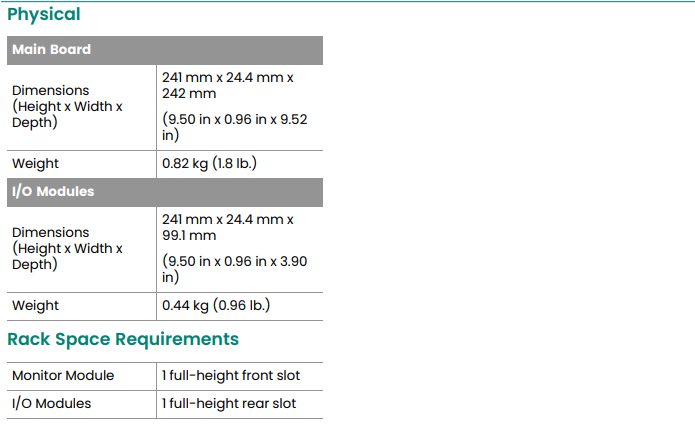

Ethernet Interface: Adopts the 10BASE-T standard with an RJ45 interface, supporting star topology and a communication rate of 10Mbps, compliant with IEEE 802.3 standards. This interface serves not only as a data transmission channel but also as the primary means for the 3500 chassis to communicate with engineering stations (running configuration software) or data servers (running data acquisition software). It supports remote configuration, diagnostics, and firmware upgrades, significantly facilitating system maintenance and management.

Serial Interface: Supports RS232, RS422, and RS485 modes, allowing users to choose different I/O modules (e.g., ModbusRS232/RS422, ModbusRS485) based on practical applications. RS232 is suitable for short-distance, point-to-point reliable communication, often used to connect local display terminals or programmers. RS422 and RS485 support differential signal transmission, offering stronger anti-interference capabilities and longer transmission distances (RS485 can reach up to 4,000 feet). They support multi-drop network topology, making them ideal for connecting PLCs, DCSs, or other distributed control units, providing a robust bridge for integrating traditional industrial automation systems.

3. High-Performance Data Acquisition and Processing

The 3500/92 exchanges data with other modules in the chassis (e.g., vibration monitoring, temperature monitoring, speed monitoring) via a high-speed internal bus, collecting information such as real-time measured values, timestamps, module statuses, and alarm statuses. Its data acquisition mechanism combines periodic and event-triggered methods, ensuring that any important status changes are promptly captured and reported.

The data update rate depends on the chassis configuration but does not exceed 1 second, ensuring real-time performance and accuracy. This high-efficiency data processing capability enables upper-level systems to grasp the health status of monitored machinery in near real-time, providing a solid data foundation for predictive maintenance and fault diagnosis.

4. Configurable Modbus Registers

Compared to the earlier 3500/90 module, the 3500/92 offers a Configurable Modbus Register Utility, allowing users to flexibly define register mapping relationships to better adapt to the data requirements of different control systems. This feature eliminates the constraints of traditional fixed-mapping gateways, enabling engineers to map specific monitoring points (e.g., vibration values, temperature values, alarm statuses of a particular channel) to specific holding register or input register addresses in the Modbus protocol. This flexibility greatly simplifies the complexity for third-party systems (e.g., SCADA, DCS, PLC) to access 3500 system data, eliminating the need for complex data address conversions in third-party systems. It achieves seamless integration and reduces engineering development and post-maintenance workload.

5. Low-Power Design and High Reliability

Typical power consumption is only 5.0–5.6 watts, making it suitable for high-density chassis deployment and effectively reducing the overall system's energy consumption and thermal load.

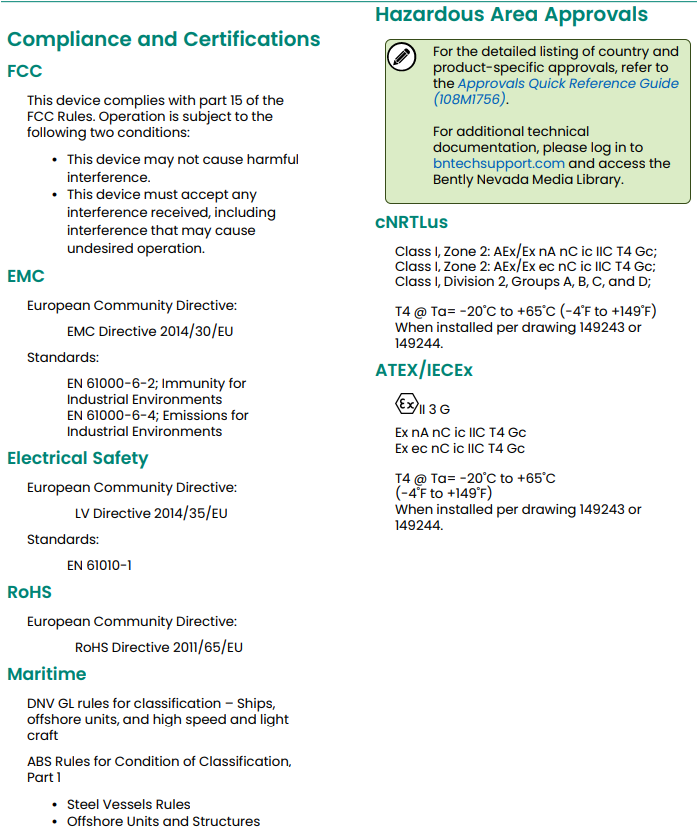

Wide operating temperature range (-30°C to +65°C) and humidity tolerance up to 95% (non-condensing) ensure good environmental adaptability. Its design follows strict industrial standards with carefully selected components, enabling stable operation in harsh industrial environments (e.g., high temperature, high humidity, strong electromagnetic interference). Its long Mean Time Between Failures (MTBF) guarantees the reliability required for 7x24 uninterrupted operation of critical monitoring systems.

6. Status Indication and Diagnostics

The front panel is equipped with an OK LED and a TX/RX LED, indicating the module's operational status and data communication status, respectively, facilitating on-site maintenance and troubleshooting. A steady green OK light indicates that the module has passed self-test and is operating normally; a blinking TX/RX light indicates that the module is exchanging data with other chassis modules via the internal bus. This intuitive visual indication provides technicians with first-hand information to quickly assess the gateway's basic status, serving as an effective tool for preliminary fault localization.

Detailed Working Principle

1. Data Flow Architecture

The 3500/92, as a communication gateway, occupies a core position in the 3500 monitoring system. Its data flow is divided into three layers:

Data Acquisition Layer: Periodically reads data from various monitoring modules (e.g., 3500/45, 3500/50) via the chassis's internal high-speed bus. This process is active; the gateway acts as a master device on the bus, polling each monitoring module according to a preset scan cycle to collect their latest data packets. These packets contain rich information, not only processed engineering values (e.g., µm pp, mm/s, °C) but also raw waveform and spectrum data (depending on module type and configuration), as well as detailed module and channel status words (health status, alarm/danger status, bypass status, etc.).

Data Processing Layer: Processes the acquired data by packaging, timestamp alignment, and protocol encapsulation. The gateway internally maintains a dynamic data image area that reflects the latest status of the entire chassis. When a data request is received from an upper-level system, the gateway retrieves the data quickly from this image area rather than immediately scanning the modules, ensuring response speed. For data requiring timestamp alignment (e.g., needing to record the status of multiple measurement points at a specific moment simultaneously), the gateway ensures temporal consistency. Subsequently, according to the rules of the target protocol (Modbus/TCP, Modbus RTU), it converts the internal data format into standard Protocol Data Units (PDUs).

Communication Output Layer: Sends data to upper-level systems based on the configured protocol type (Modbus/TCP, Modbus RTU, BNC protocol, etc.). This layer handles the underlying communication details of the network or serial interface. For Modbus/TCP, it listens on a designated TCP port (usually 502), parses received Modbus/TCP frames, executes the contained Modbus function codes (e.g., 03 Read Holding Registers, 04 Read Input Registers), and constructs response frames by extracting corresponding data from the data image area. For Modbus RTU, it manages serial port parameters like baud rate, data bits, stop bits, and parity, framing and deframing according to the RTU format. For the BNC protocol, it handles encrypted and authenticated communication with Bently Nevada proprietary software.

2. Protocol Processing Mechanism

Modbus RTU Mode: Uses RTU (Remote Terminal Unit) transmission mode, where data is transmitted in binary format, offering high efficiency and suitability for serial communication. Each RTU message starts and ends with a silent interval (at least 3.5 character times) and includes slave address, function code, data field, and CRC check code. The gateway can act as a slave responding to queries from a master (e.g., PLC) or, in some configurations, as a master querying other slave devices.

Modbus/TCP: Implemented on top of TCP/IP, each Modbus frame is embedded within a TCP packet, supporting multi-client connections and suitability for networked environments. The Modbus/TCP frame has a special MBAP header (Modbus Application Protocol Header) containing a transaction identifier, protocol identifier, length, and unit identifier (often used as the slave address). The gateway's built-in TCP/IP stack handles network connections, data packet segmentation, and reassembly, thus shielding the Modbus application layer from network complexities.

BNC Host Protocol: Designed specifically for Bently Nevada software, supporting configuration deployment, data querying, firmware upgrades, and other functions. This is a more advanced, feature-rich private protocol. It not only transmits real-time data but is also used to transfer entire chassis configuration information (download to or upload from the gateway), execute diagnostic commands, and manage user sessions and security authentication. It typically operates on higher TCP ports, and communication content is often encrypted to ensure the security of system configuration and data.

3. Network and Interface Technology

Ethernet Communication: Supports 10Mbps speed, uses an RJ45 interface, and can connect to switches or host computers via standard Cat5 shielded cables. Its network stack supports standard protocols like ARP, IP, ICMP, TCP, and UDP, ensuring compatibility with existing enterprise networks. The gateway's IP address can usually be set via front panel DIP switches or configuration software.

Serial Communication: RS485 supports multi-drop bus topology with a maximum transmission distance of 4,000 feet (1,220 meters), suitable for distributed systems; RS232 is suitable for point-to-point short-distance communication. RS485 uses balanced differential signals, offering strong common-mode noise rejection. The gateway's RS485 interface typically supports Auto-Direction Control, simplifying driver development. When networking, termination resistors must be installed at both ends of the bus to match impedance and reduce signal reflection.

4. Redundancy and Scalability

Supports various I/O module options, allowing users to select different types of modules (e.g., composite modules with Ethernet + serial ports) based on communication needs. This modular design enables flexible configuration according to the number and type of communication interfaces required for actual projects, eliminating the need to purchase entirely new gateways for different interface requirements, thus protecting investment and enhancing system adaptability.

Multi-chassis cascading can be achieved using extension cables to build large-scale monitoring networks. When using RS485 I/O modules, gateways from multiple 3500 chassis can be connected in series via an RS485 bus, forming a daisy-chain network. One gateway is designated as the master, responsible for communicating with the upper-level control, while other gateways act as transparent repeaters. This architecture allows monitoring data from multiple chassis physically dispersed in different locations to be aggregated and transmitted over a single bus, significantly saving wiring costs and the number of communication interfaces required by the control system. It enables centralized data management for truly large-scale, distributed machinery condition monitoring systems.