The IS220PDIAH1B Discrete Input Module is a critical interface device within the Mark VIe control system, specifically designed for acquiring switch status signals. As a functionally enhanced version of the PDIA series I/O modules, it incorporates the BPPC processor board, offering significant improvements in compatibility, environmental adaptability, and diagnostic capabilities. This module is specifically engineered to process various dry contact signals from the industrial field, such as limit switches, relay contacts, and pushbutton statuses, and convert them into digital signals processable by the Mark VIe controller.

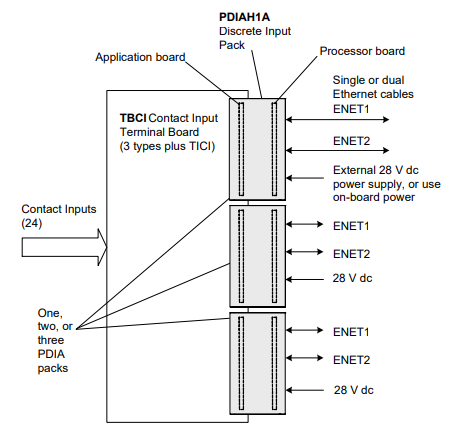

The IS220PDIAH1B module connects to the system's IONet network via dual RJ-45 Ethernet interfaces, supporting flexible system configurations including Simplex, Dual, and Triple Modular Redundant (TMR) architectures. Its core function is to provide the control system with reliable and precise discrete status inputs, while incorporating comprehensive self-diagnostic and protection mechanisms to ensure stable operation in harsh industrial environments.

2. System Architecture and Hardware Design

2.1 Module Hardware Composition

The IS220PDIAH1B adopts a modular design, primarily consisting of three core components:

BPPC Processor Board: Acts as the module's "brain," responsible for communication coordination with the upper-level controller, data processing, and diagnostic management. Compared to its predecessor, the BPPC provides enhanced processing power and more complete software support (requires ControlST* software suite V04.04 or later).

Discrete Input Acquisition Board: Hardware dedicated to discrete signal conditioning, responsible for receiving raw signals from the terminal board, performing level shifting, isolation, and shaping.

DC-37-pin Connector: Located on the bottom of the module, used for direct plug-in connection to the discrete input terminal board, transmitting 24 input signals, ID recognition signals, relay coil power, and feedback multiplexing commands.

2.2 Interfaces and Connections

The module side provides a complete set of system interfaces:

ENET1 and ENET2: Two RJ-45 Ethernet interfaces supporting single or dual network connections for communication redundancy. Standard practice is to connect ENET1 to the network associated with the R controller.

3-pin Power Connector: Input for 28V DC power, supplying the I/O module itself and the connected terminal board. The module features soft-start capability, effectively suppressing inrush current during power-up and allowing hot plugging of the power connector.

2.3 Environmental Adaptability

The IS220PDIAH1B boasts a wider operating temperature range (-40°C to 70°C), compared to the PDIAH1A (-30°C to 65°C), making it more suitable for extremely harsh industrial environments and demonstrating its enhanced robustness.

3. Core Functions and Operating Principles

3.1 Discrete Signal Acquisition and Conditioning

The core task of the IS220PDIAH1B is to accurately and reliably acquire the status of 24 field dry contacts. Its signal processing flow reflects sophisticated electronic design:

Two-Stage Signal Conditioning:

Primary Conditioning on Terminal Board: The terminal board provides the wetting voltage (supports 24V DC, 48V DC, or 125V DC) and applies it to the field contact through a current-limiting resistor. When the contact closes, a loop is formed, generating an input current.

Secondary Conditioning in I/O Module: The acquisition board receives the voltage signal from the terminal board and performs further conditioning, including filtering and level shifting, to conform to the processor's standard recognition levels.

Optical Isolation: Each input channel is electrically isolated from the control logic through an opto-coupler, rated for 1500V. This effectively prevents interference such as voltage surges and ground potential differences from the field side from entering the control system side, significantly enhancing the system's noise immunity and safety. It is important to note that the 24 input channels are not isolated from each other.

3.2 Variable Threshold Detection and Intelligent Diagnostics

This is a key technology employed by the IS220PDIAH1B to ensure input accuracy:

Dynamic Threshold Calculation: The comparator threshold for input detection is not fixed but is derived from the contact wetting voltage input from the terminal board. In most applications, this voltage is scaled to provide a 50% input detection threshold. For example, with a 125V DC wetting voltage, the threshold is approximately 62.5V.

Threshold Clamping Protection: To prevent an indeterminate input state if the wetting voltage drops to zero, the threshold is clamped to a minimum of 13%.

Undervoltage Detection: If the contact wetting voltage falls below 40% of the nominal voltage, an undervoltage detector annunciates this condition to the control system, indicating unreliable signal quality.

Pulse Test Mode: The module automatically executes a diagnostic test every 4 seconds. In this mode, the threshold is forcibly pulsed high and then low, and the system checks the response of the optocouplers. Any input channel that fails to respond correctly to this test pulse is flagged as faulty and generates an alarm. This mechanism effectively detects potential issues like optocoupler aging, open circuits, or external wiring faults.

3.3 Input Filtering and Status Indication

Hardware Filtering: Each input channel is equipped with a 4-millisecond hardware filter, effectively suppressing transient glitches caused by contact bounce or electromagnetic interference, ensuring stable status readings.

AC Voltage Rejection: With 125V DC wetting, the module possesses 60V RMS (50/60Hz) AC common-mode rejection capability, allowing accurate DC signal recognition in environments with AC interference.

Field Status Indication: The module front features yellow status LED indicators for each of the 24 input channels. When an input is energized (contact closed, signal active), the corresponding LED lights up; when the input is de-energized (contact open), the LED turns off. This provides maintenance personnel with an intuitive means of status determination during field debugging and maintenance.

4. Compatibility and System Configuration

4.1 Broad Terminal Board Compatibility

The IS220PDIAH1B is compatible with a wide range of discrete input terminal boards, covering different voltage levels and application scenarios:

Standard Industrial Voltages: TECH2C (24V DC), TECH3C (48V DC), TECH1C/TECH5C (125V DC), etc.

Hazardous Location Applications: TECH4C and STCH8A terminal boards are specifically designed for hazardous environments.

Safety-Certified Systems: Certain terminal boards (e.g., STCIS2A, STCIS4A) are IEC 61508 safety certified when used with the YDIA I/O pack, making them suitable for the Mark VIeS Safety Control System.

AC Signal Acquisition: Terminal boards like TICIH1A support AC wetting (115/230V AC), expanding the application range.

4.2 Flexible Redundancy Architectures

The IS220PDIAH1B supports three main system configuration modes to meet varying reliability requirements:

Simplex Configuration: Uses one IS220PDIAH1B module with single or dual network connections. Dual networks provide communication path redundancy.

Dual Configuration: Uses two IS220PDIAH1B modules, each with one network connection. The modules operate in parallel, and the controller evaluates the inputs.

Triple Modular Redundant (TMR) Configuration: Uses three IS220PDIAH1B modules, connected to the R, S, and T controller channels respectively. The controller performs a "two-out-of-three" vote on the inputs, achieving the highest level of availability. Compatible TMR terminal boards (e.g., TECH series) provide three independent DC-37 connectors, allowing the simultaneous installation of three PDIA modules.

5. Installation and Wiring Specifications

5.1 Mechanical Installation

The installation process is designed for simplicity and reliability:

Securely mount the selected terminal board onto the panel.

Align the IS220PDIAH1B module directly and plug it into the terminal board's DC-37-pin connector.

Use the threaded studs adjacent to the Ethernet ports to slide the module into the mounting bracket specific to the terminal board type. The bracket position must be adjusted to ensure no right-angle force is applied to the DC-37 connector. This adjustment is typically required only once during the product's service life.

5.2 Key Wiring Principles

Correct wiring is fundamental to avoiding misoperation and equipment damage:

Voltage Type Distinction: AC wetting and DC wetting terminal boards must be strictly distinguished. Mixing them is prohibited as it causes malfunction and hardware damage.

Special Terminal Board Wiring (TECH4C/STCH8A):

Dedicated Lines: Each wetting voltage output can only connect to one field contact (i.e., "home run" or "star" wiring).

Parallel Connection Prohibited: Branching one wetting voltage output to multiple contacts is forbidden, as it causes misoperation and self-test failures.

Ground Fault Detection: When using these terminal boards, the ground fault detection threshold for the connected JPDE power distribution board must be set to 4V DC in the ToolboxST software to ensure sensitive detection of ground shorts.

6. Diagnostics and Maintenance Functions

The IS220PDIAH1B integrates a multi-level self-diagnostic system, ensuring operational reliability:

Power-Up Self-Test: Includes checks of RAM, Flash memory, Ethernet ports, and most processor board hardware.

Continuous Power Supply Monitoring: Internal power supply voltages are continuously monitored to ensure operation within normal ranges.

Hardware Identity Verification: Checks electronic ID information from the terminal board, acquisition board, and processor board to confirm hardware set compatibility and verifies that the loaded application code is correct for the hardware set.

Wetting Voltage Loss Detection: Monitors for the loss of contact wetting voltage on the terminal board.

Input Channel Response Test: Diagnoses non-responsive contact inputs via the aforementioned pulse test mode.

All this diagnostic information is transmitted to the upper-level controller via the IONet and displayed in the ToolboxST software, facilitating quick fault localization and troubleshooting for maintenance personnel.