The IS200JPDGH1A Power Distribution Board is a critical power management core component within GE's Mark VIe and Mark VIeS control systems, serving as a central hub in the Power Distribution System (PDM). This product is specifically designed for complex power distribution requirements in industrial control environments, providing reliable power assurance for the stable operation of the entire control system.

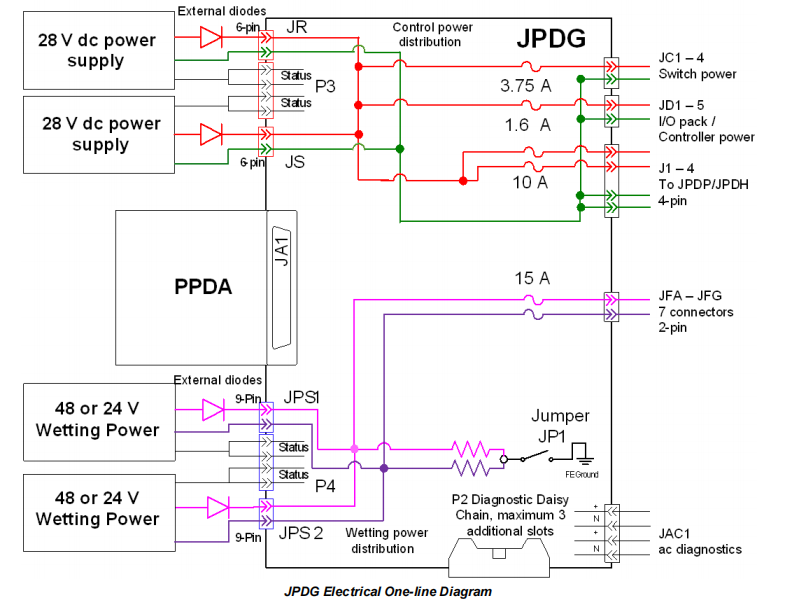

As a core unit in the power distribution architecture, the IS200JPDGH1A undertakes dual power distribution tasks: on one hand, it handles 28V DC control power distribution to supply critical equipment such as controllers, I/O modules, and network switches; on the other hand, it manages 24V/48V DC wetting power distribution to provide operating power for contact input/output terminal boards. This clearly divided power management system ensures that different types of loads receive stable and reliable power supply.

In modern industrial control systems, the reliability and intelligence level of power distribution directly affect the availability and maintenance efficiency of the entire system. Through integration of advanced power monitoring, fault diagnosis, and ground detection functions, the IS200JPDGH1A achieves the transition from simple power distribution to intelligent power management. Its design fully considers various harsh conditions in industrial environments, including temperature fluctuations, electrical noise, and mechanical vibrations.

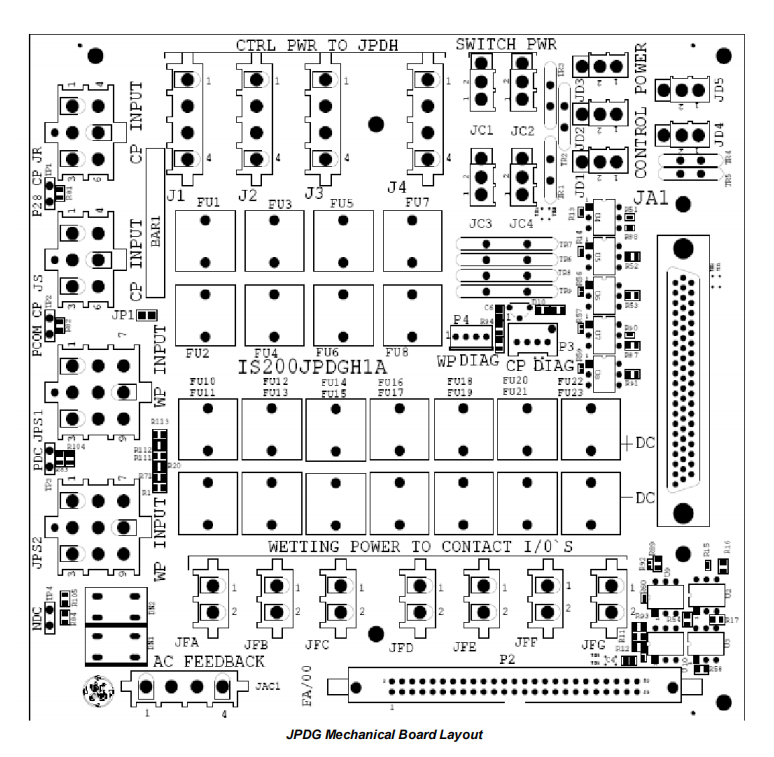

2. Hardware Architecture and Interface Design

The hardware design of the IS200JPDGH1A power distribution board reflects the high reliability and modular concept of industrial-grade products, with its architecture optimized around the core function of power distribution:

Power Input Interface System:

28V DC Control Power Input: Equipped with two 6-pin Mate-N-Lok connectors (JR and JS), each connector uses multiple pins in parallel design (pins 1-3 for power return, pins 4-6 for positive) to form a bus system with capacity up to 40A (at 55°C). This redundant input design achieves "OR" logic through external diodes, ensuring system power supply is not affected by single power source failure.

24V/48V DC Wetting Power Input: Accessed through two 9-pin Mate-N-Lok connectors (JPS1 and JPS2), also using multiple pins in parallel scheme (pins 1-4 for return, pins 6-9 for positive), supporting maximum 40A steady-state current capacity. Input voltage can be selected between 24V DC or 48V DC, but must be unified within the same system.

Power Output Interface System:

High-power Output Interface: Four 4-pin Mate-N-Lok connectors (J1-J4) specifically supply power to remote power distribution boards (JPDP/JPDH), with each output branch equipped with 10A slow-blow fuses (such as Bussmann MDA-10) on the positive line for overcurrent protection.

Control Equipment Power Supply Interface: Five 2-pin Mate-N-Lok connectors (JD1-JD5) supply power to I/O modules and controllers, protected by self-resetting fuses with ratings automatically adjusted according to ambient temperature (0.9A at 55°C, 0.5A at 70°C).

Network Equipment Power Supply Interface: Four 2-pin connectors (JC1-JC4) specifically supply power to network switches, also using temperature-dependent self-resetting fuses for protection.

Wetting Power Output Interface: Seven 2-pin Mate-N-Lok connectors (JFA-JFG) provide wetting power for contact I/O terminal boards, with each branch equipped with 15A fuses on both positive and negative lines, but actual operating current limited to 10A (at 55°C) for safety.

Auxiliary Function Interfaces:

PPDA I/O Module Interface: 62-pin D-shell connector (JA1) for connecting power system feedback modules to achieve intelligent power management.

Diagnostic Data Interface: 50-pin ribbon cable connector (P2) for receiving diagnostic feedback signals from other power distribution boards.

Power Status Monitoring Interface: 4-pin connectors (P3 and P4) monitor status switch signals of 28V and 24/48V power supplies respectively.

3. Core Functions and Working Principles

The functional implementation of the IS200JPDGH1A power distribution board is based on precise electrical design and intelligent monitoring mechanisms, with its working principles involving multiple technical aspects:

3.1 Dual Power Distribution Mechanism

Control Power Distribution Principle:

The 28V DC control power distribution adopts a layered protection strategy. Input power is redundantly configured through external diodes to form a unified power bus. This bus is then distributed to four independent branches, each protected by 10A fuses against overcurrent. This design ensures both power supply reliability and local isolation of faults, preventing single branch failures from affecting the entire system.

A key innovation in the power distribution process is the application of self-resetting fuses. For sensitive control equipment power supply, the JD series outputs use self-resetting fuses, whose resistance characteristics automatically adjust with temperature changes. When ambient temperature rises, the fuse trip threshold correspondingly decreases, providing optimal protection characteristics for equipment through this temperature-adaptive feature.

Wetting Power Distribution Principle:

The 24V/48V wetting power distribution uses a floating bus design, achieving ground fault detection through center grounding resistors. Under normal operating conditions, the positive bus-to-ground voltage is half of the power supply voltage (12V for 24V systems, 24V for 48V systems), and the negative bus-to-ground voltage is the corresponding negative value. This symmetrical configuration ensures that any ground fault on either pole disrupts the voltage balance, thus being detected by the monitoring system.

The wetting power output branches use bidirectional fuse protection, meaning fuses are installed on both positive and negative lines. This dual protection design effectively handles various types of line faults, including positive-to-ground shorts and negative-to-ground shorts.

3.2 Intelligent Ground Fault Detection System

The IS200JPDGH1A's ground fault detection system is based on the resistor center grounding principle, which is its most core technical feature:

Detection Principle:

The JP1 jumper selects whether to use the onboard 12kΩ center resistors. When JP1 is closed, the positive and negative buses are connected to functional ground (FE) through 12kΩ resistors, forming a voltage divider circuit. In fault-free state, the positive and negative bus-to-ground voltages are equal in absolute value; when any bus experiences a ground fault, the voltage balance is disrupted, and the detection circuit identifies the fault by measuring changes in bus-to-ground voltages.

System Configuration:

In complex power distribution systems, multiple distribution boards may share the same wetting power bus. The JPDG features intelligent resistor configuration logic: when both JPDG and JPDE distribution boards are used in the system, only one board can enable the center resistor function. This configuration prevents detection sensitivity degradation caused by parallel resistors, ensuring reliability of ground fault detection.

3.3 AC Power Diagnostic Function

Although the IS200JPDGH1A does not directly distribute AC power, it provides two-channel AC power monitoring functionality:

Signal Acquisition Principle:

AC signals of 115V or 230V are accessed through the JAC1 connector, with onboard sensing circuits converting AC signals to low-voltage signals suitable for measurement. The acquisition circuit uses differential input design to accurately measure voltage between phase and neutral lines.

Diagnostic Mechanism:

The measurement system provides voltage readings with ±4% full-scale accuracy, transmitting data to the control system through the PPDA module. This enables operators to monitor AC power status in real-time and promptly identify power quality issues.

3.4 Comprehensive Diagnostic Feedback System

The IS200JPDGH1A's diagnostic system employs advanced signal aggregation technology:

Signal Integration:

Due to the large number of signals that the IS200JPDGH1A needs to monitor, a single feedback signal set is insufficient to transmit all diagnostic information. Therefore, the JPDG occupies three of the six available feedback signal sets in the PPDA, including:

Electronic ID information (board type, revision number, and serial number)

28V and 24/48V bus voltage measurements (accuracy ±1%)

All fuse status feedback

DC power converter status signals

Test point access signals

Intelligent Diagnostics:

The diagnostic system features configurable enable/disable functions, allowing users to select which power inputs to monitor according to actual needs. When input voltage falls below preset thresholds (5V for 28V systems, 10V for 24V systems), related diagnostic information is automatically suppressed to avoid false alarms.

4. Installation and Configuration Specifications

Mechanical Installation:

The IS200JPDGH1A adopts vertical mounting method, fixed to metal brackets with four screws. Board dimensions are 16.51cm high × 17.8cm wide, using DIN rail mounting method. Installation position is typically chosen in the lower part of the control cabinet for convenient grounding connections and cable routing.

Electrical Connections:

Protective earth (PE) connections must comply with local standards, with minimum grounding capability required to withstand 60A current for 60 seconds, with voltage drop not exceeding 10V.

Functional earth (FE) is connected to the base through metal brackets, serving as signal reference ground.

All power connections must observe polarity to ensure correct connection of positive and negative terminals.

System Configuration:

JP1 jumper configuration depends on system grounding requirements: close JP1 when the board needs to provide center grounding function; keep JP1 open when using external center resistors or when other distribution boards provide this function.

Configure diagnostic parameters through ToolboxST software, including input diagnostic enable, dry contact configuration, etc.

5. System Integration and Compatibility

The IS200JPDGH1A occupies a core position in the power distribution system, working in coordination with various power distribution boards:

Compatibility Configuration:

Can be combined with auxiliary distribution boards such as JPDE (24V or 125V), JPDB (AC), etc.

Not compatible with simultaneous use of JPDS, JPDM, or JPDC

Allows maximum one JPDB and one JPDE, but can be paired with two JPDFs

PPDA Integration:

Directly hosts the PPDA I/O module through the JA1 connector, achieving centralized monitoring of the power system. This tight integration simplifies wiring and improves system reliability.

6. Safety Features and Maintenance Support

Protection Mechanisms:

Multi-level fuse protection: including replaceable fuses and self-resetting fuses

Redundant power inputs: achieving power redundancy through external diodes

Ground fault detection: early identification of insulation degradation issues

Maintenance Functions:

Abundant test points (TP1-TP4) for convenient field measurements

Detailed fuse status monitoring

Power supply status contact monitoring